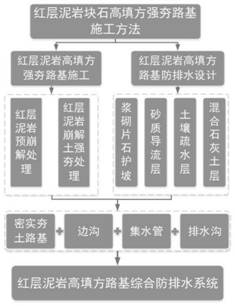

Construction method using red-layer mudstone as high-fill dynamic compaction roadbed filler

A technology for red-bed mudstone and roadbed filler is applied in the field of dynamic compaction construction of red-bed mudstone high-fill roadbed, which can solve the problems of complex construction process, low efficiency, and no construction technical scheme is proposed, so as to simplify construction operation steps and reduce construction. Steps, avoid the effect of filling duplication of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

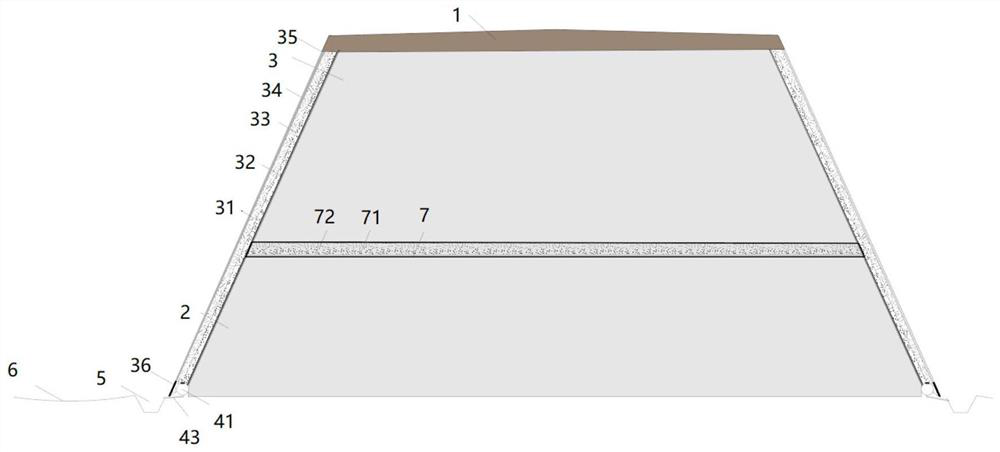

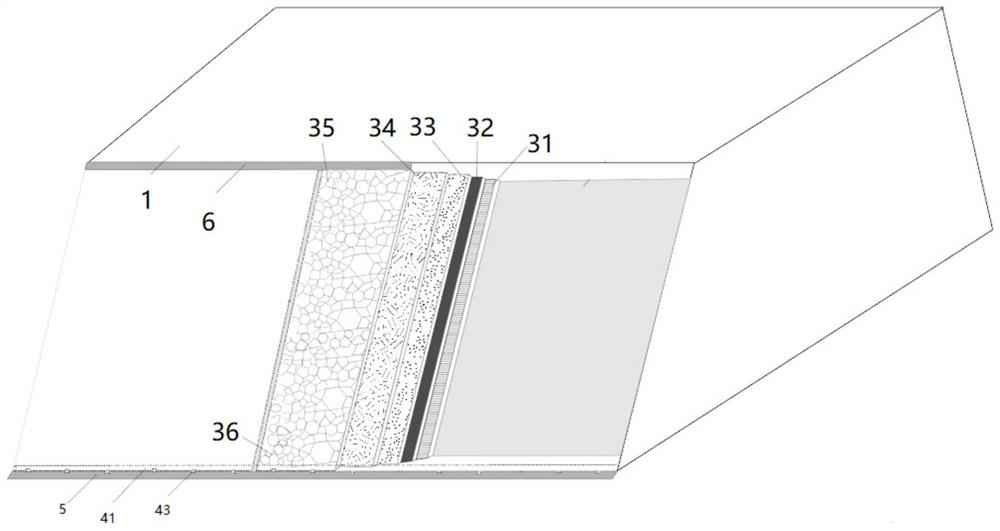

[0040] see Figures 1 to 4 ,

[0041] A construction method using red-bed mudstone blocks as high-fill dynamic compaction subgrade filler,

[0042] Include the following steps:

[0043] S1. Perform pre-disintegration treatment on the red bed mudstone, and expose the blasted red sandstone filler to the atmosphere, sunlight and rain without covering. The total number of days for the pre-disintegration treatment is 8 to 15 days.

[0044] Under the action of these natural factors, the red bed mudstone weathered and disintegrated rapidly, its strength decreased sharply, and its activity was rapidly eliminated.

[0045] S2. The pre-disintegrated red sandstone filler can be transported to the embankment for filling, and then undergo dynamic compaction treatment, first point compaction twice, and then full compaction once.

[0046] The processing method of this step is to tamp the embankment filler, accelerate the drainage and consolidation of the filler, and increase the compactne...

Embodiment 2

[0057] see Figures 1 to 4 ,

[0058] A construction method using red-bed mudstone blocks as high-fill dynamic compaction subgrade filler,

[0059] Include the following steps:

[0060] S1. Pre-disintegrate the red mudstone, and expose the blasted red sandstone filler to the atmosphere, sunlight and rain without cover. When the highest temperature is higher than 30°C in sunny days, water once a day. The temperature in sunny days is the lowest. When the high temperature is lower than 30°C, water once every other day, and the total number of days for pre-disintegration treatment is 8 to 15 days. The method for judging whether the red bed mudstone has been disintegrated is that large pieces of newly disintegrated red sandstone with a particle size of 50-70 cm, after several days of pre-disintegration treatment, a large number of cracks have appeared on the surface and most of the fragmented rocks have disintegrated. When pushing with the soles of the feet, the large rock block...

Embodiment 3

[0074] see Figures 1 to 4 ,

[0075] A construction method using red-bed mudstone blocks as high-fill dynamic compaction subgrade filler,

[0076] Include the following steps:

[0077] S1. Pre-disintegrate the red mudstone, and expose the blasted red sandstone filler to the atmosphere, sunlight and rain without cover. When the highest temperature is higher than 30°C in sunny days, water once a day. The temperature in sunny days is the lowest. When the high temperature is lower than 30°C, water once every other day, and the total number of days for pre-disintegration treatment is 8 to 15 days. The method for judging whether the red bed mudstone has been disintegrated is that large pieces of newly disintegrated red sandstone with a particle size of 50-70 cm, after several days of pre-disintegration treatment, a large number of cracks have appeared on the surface and most of the fragmented rocks have disintegrated. When pushing with the soles of the feet, the large rock block...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com