GIS equipment mechanical fault detection system and method based on acoustic imaging

A technology of mechanical faults and detection methods, which is applied in the testing of mechanical components, radio wave measurement systems, and testing of machine/structural components. The results are not intuitive and other problems, to avoid the mixing of false sound sources, improve the anti-interference ability, and reduce the effect of variance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

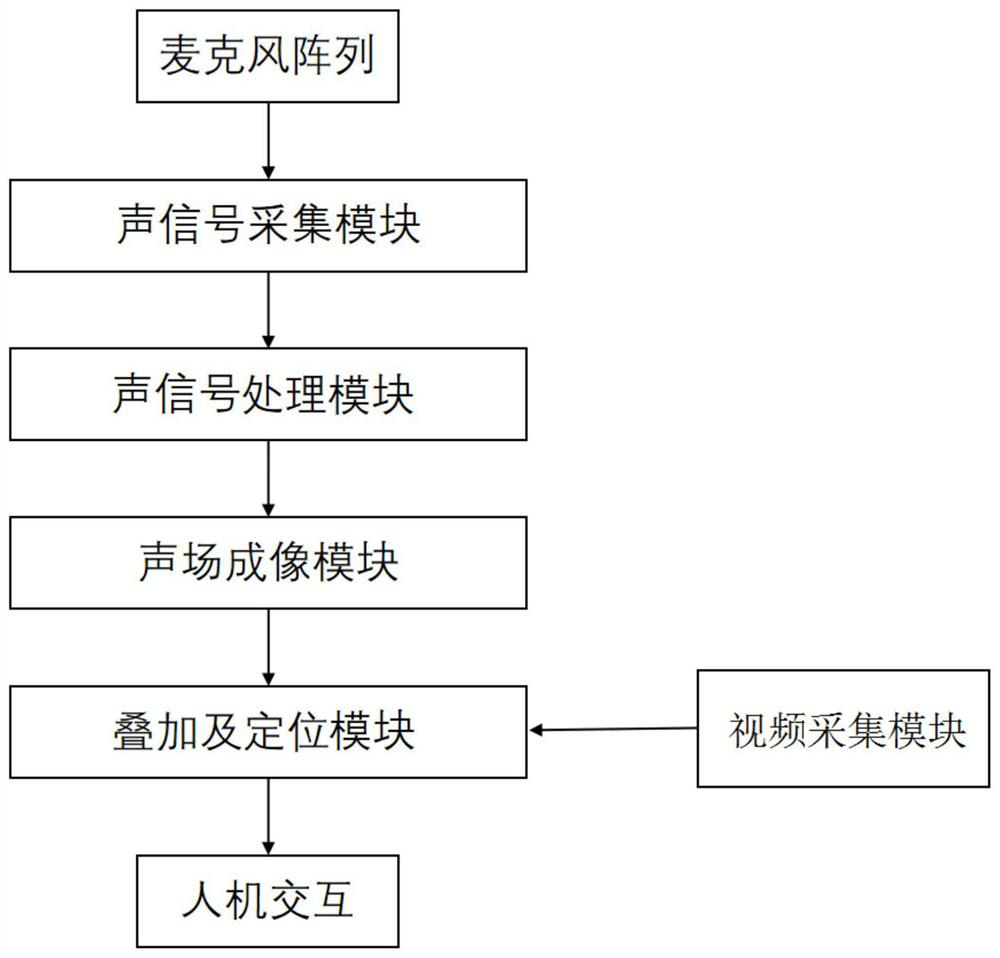

[0055] Embodiment 1 of the present invention provides a GIS equipment mechanical failure detection system based on acoustic imaging, such as figure 1 As shown, the detection system shown includes an acoustic signal acquisition module, an acoustic signal processing module, a sound field imaging module, a video acquisition module, a superimposed positioning output module, and a human-computer interaction terminal. The acoustic signal acquisition module is connected to the acoustic signal processing module. The sound field imaging module is respectively connected with the sound signal processing module, the video acquisition module and the human-computer interaction terminal;

[0056] In this embodiment, the detection system data processing adopts the FPGA storage control unit as the core processing unit, and executes the stored program algorithm through multi-task management;

[0057] The acoustic signal acquisition module includes a microphone array and an analog-to-digital con...

Embodiment 2

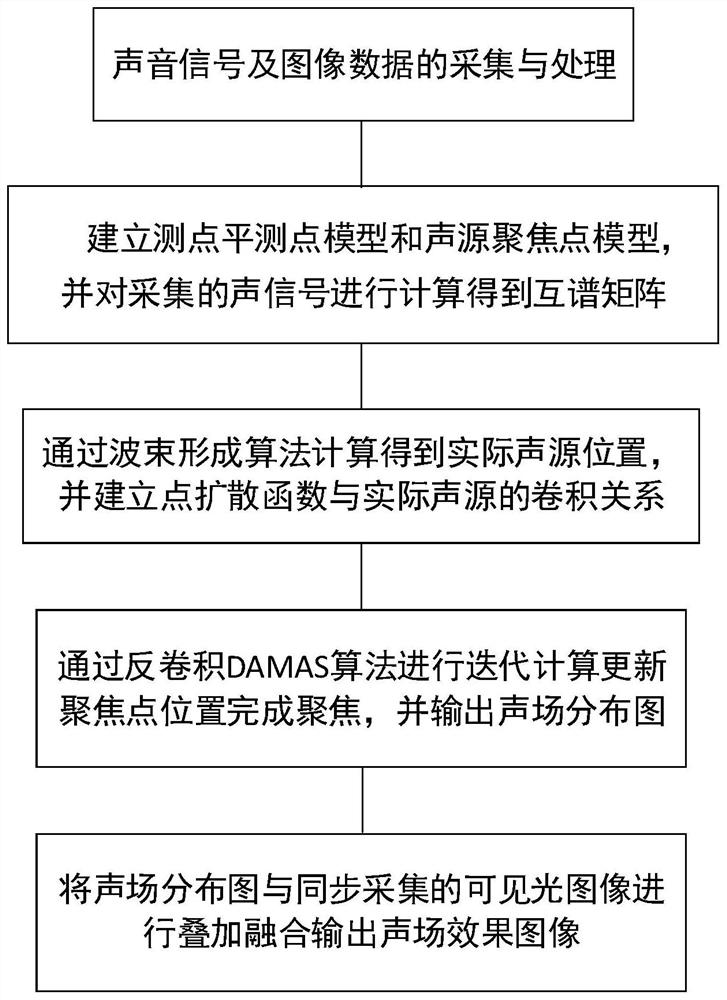

[0068] Embodiment 2 of the present invention provides a GIS equipment mechanical failure detection method based on acoustic imaging, based on the detection system in Embodiment 1 above, such as image 3 As shown, the specific steps of the detection method are as follows:

[0069] Acquisition and processing of sound signals, collecting sound field signals of the equipment to be tested, obtaining sound signals of multiple channels, and denoising and amplifying the collected sound signals;

[0070] combine Figure 4 and Figure 5 As shown, the obtained multi-channel sound signal X(n) is windowed and framed, and the i-th frame speech signal xi(m) with a frame length of N is obtained, and the obtained speech signal is subjected to fast Fourier transform. The transformed output signal is denoted as xi(k), and the noise estimation algorithm is used to calculate xi(k) to output the signal D(k). )| 2 , will |xi(k)| 2 and D(k) are used as input for spectral subtraction, and the obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com