In-situ measurement method for metal resistivity at high temperature and high pressure

A metal resistance, high temperature and high pressure technology, which is applied in the direction of measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problems of sample type limitation, inconsistency, filamentary sample deformation, etc., and meet the high-voltage experimental conditions , control product quality, good contact avoiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

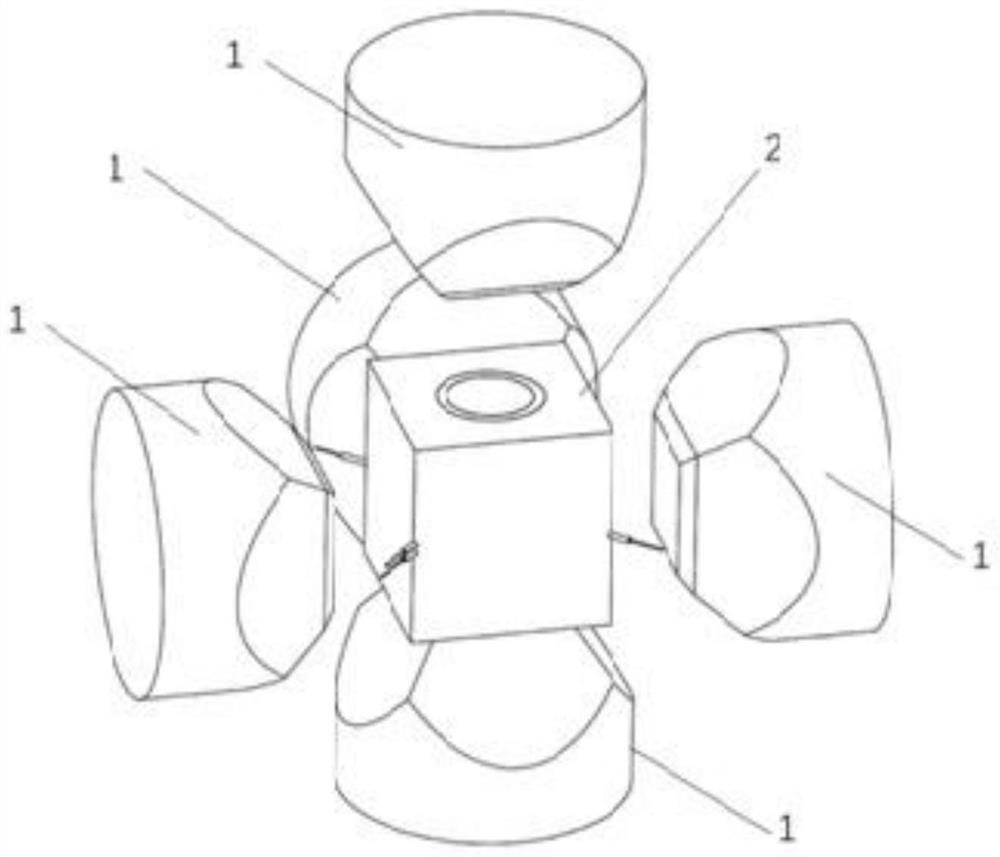

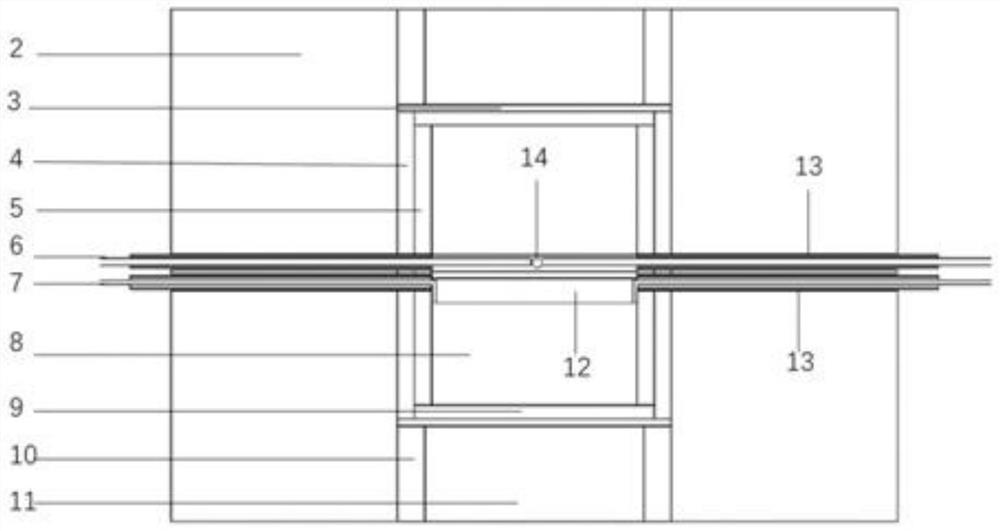

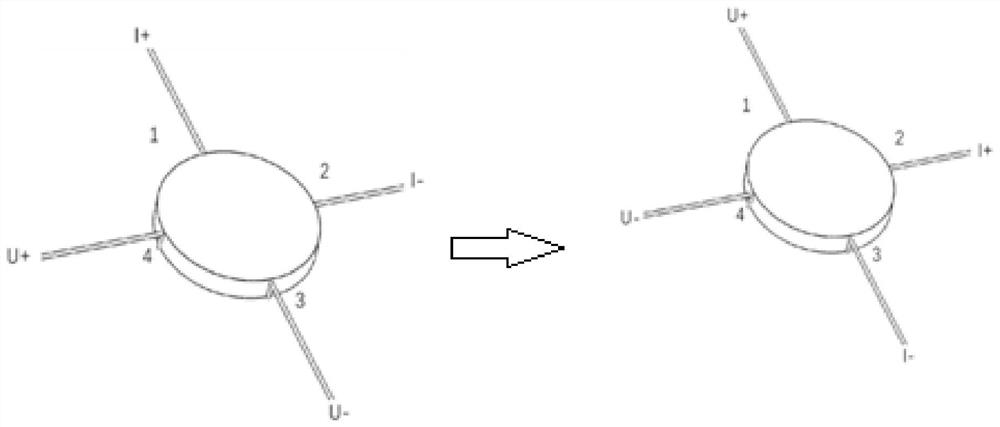

[0040] The invention provides an in-situ measurement method of metal resistivity under high temperature and high pressure. The method uses the Van der Pauw four-wire method as the measurement principle, and a domestic six-sided top large cavity press is used as an equipment platform for generating high temperature and high pressure. Use pyrophyllite as pressure medium, graphite tube and graphite sheet as heater, hexagonal boron nitride tube as sample chamber, hexagonal boron nitride cylinder as filling, metal wire as test electrode, and thermocouple wire as temperature measuring element. The method specifically includes the following steps:

[0041] S1. Processing each component:

[0042] (1) Select the pyrophyllite 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com