Method for manufacturing hot-dip galvanized steel sheet

A technology of hot-dip galvanized steel sheet and manufacturing method, which is applied in hot-dip galvanizing process, manufacturing tools, chemical instruments and methods, etc., can solve the problems of reduced productivity, decreased coating adhesion, decreased coating alloying speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

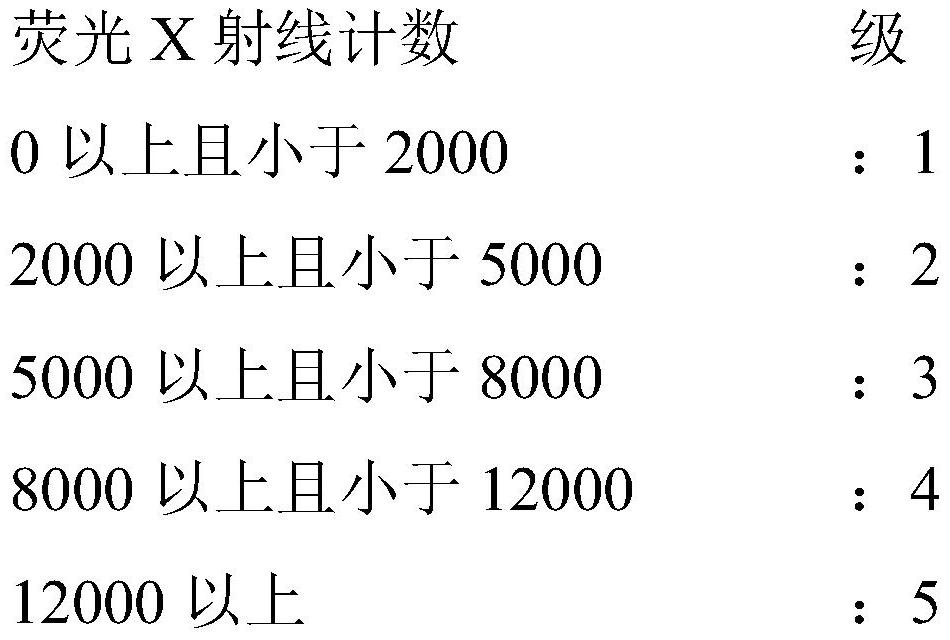

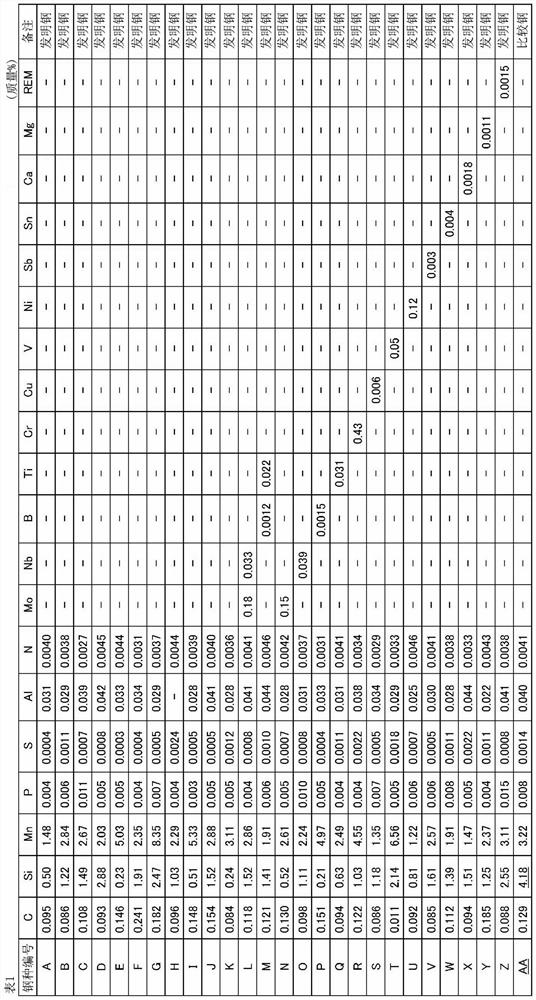

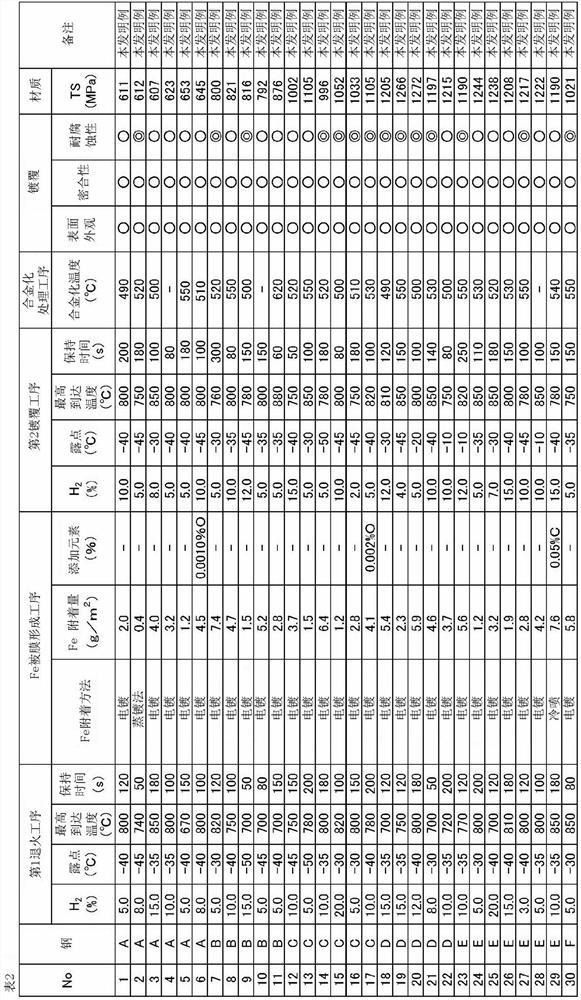

[0104] A steel having a composition containing elements shown in Table 1 and the remainder consisting of Fe and unavoidable impurities was melted in a converter and cast into a slab by a continuous casting method. The obtained slab was heated at 1240° C. for 60 minutes in a heating furnace, hot-rolled, and coiled at 550° C. to obtain a hot-rolled steel sheet. Next, pickling was performed on the hot-rolled steel sheet to remove black scale, and cold rolling was performed to obtain a cold-rolled steel sheet with a thickness of 1.4 mm. The cold-rolled steel sheet was subjected to the first annealing step, the Fe film formation step, and the second annealing step under the conditions shown in Table 2 and Table 3. It should be noted that in Table 2 and Table 3, the holding time of the first annealing step represents the time for holding the steel sheet in the temperature range of 650°C to 900°C, and the holding time of the second annealing step represents the holding time of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com