Fish-flavor essence as well as preparation method and food of fish-flavor essence

A technology of essence and fish flavor, which is applied in the field of fish flavor essence and its preparation, can solve the problems of insufficient flavor of essence and high production cost, and achieve the effect of improving color and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

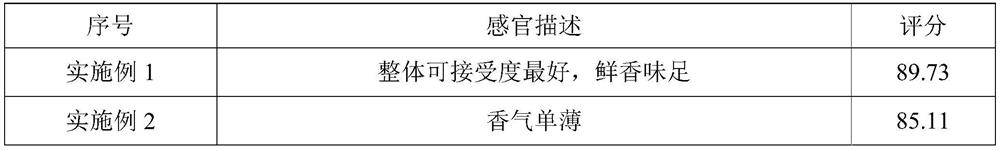

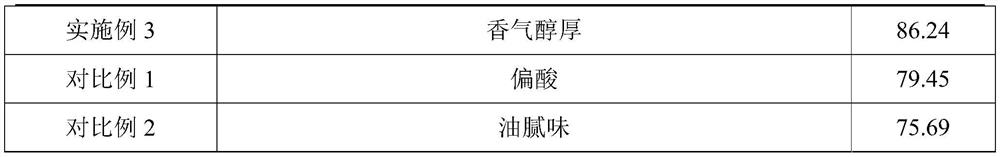

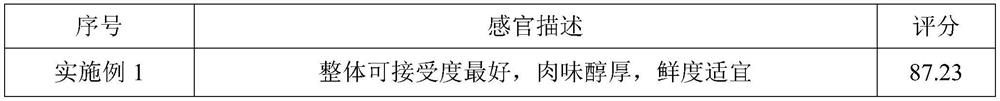

Examples

preparation example Construction

[0031] On the one hand, the present invention provides a kind of preparation method of fish flavor essence, it comprises the following steps:

[0032] After mixing the materials, carry out thermal reaction under preset pressure to prepare fish flavor;

[0033] The material includes components by weight: 20-40 parts of fish meat enzymatic hydrolysis solution, 10-30 parts of fish bone enzymatic hydrolysis solution, 1-5 parts of glucose, 0.2-1 part of yeast extract, 0.2-0.5 parts of thiamine, plant 2-4 parts of protein hydrolyzate, 1.5-4 parts of amino acid and 0.2-0.5 parts of disodium nucleotide;

[0034] Wherein the preparation method of fish enzymatic hydrolyzate comprises:

[0035] Mix and heat minced fish meat with a solid-to-liquid ratio of (1-3):5 and water, add 0.1wt%-0.2wt% flavor protease and 0.05wt%-0.1wt% animal protease for enzymolysis, and inactivate the enzyme live;

[0036] Among them, the specific activity of flavor protease is 100,000-300,000 u / g, and that o...

Embodiment 1

[0063] The flavor protease and animal protease used in this example are enzymes with a specific activity of 200,000 u / g from Nanning Pangbo Biological Co., Ltd.

[0064] 1) Preparation of fish enzymatic hydrolyzate

[0065] Cut the fresh fish meat into 3cm-sized pieces, and mince the fish meat, and mix the minced fish meat with ultrapure water evenly according to the ratio of material to liquid: 2:5. Then use a water bath to heat to 40°C, then add 0.15wt% flavor protease and 0.05wt% animal protease, after 60 minutes of enzymolysis, raise the temperature to 100°C, and keep it for 20 minutes to inactivate the enzyme. Then cool to room temperature to prepare fish enzymatic hydrolyzate.

[0066] 2) Preparation of fish bone enzymatic hydrolyzate

[0067] Put the fish bones in a grinder to grind them to form a fish bone paste, then mix the fish bone paste and ultrapure water according to the material-to-liquid ratio of 1:5, heat to 40°C in a water bath, and add 0.3wt% animal Carr...

Embodiment 2

[0071] The preparation method of this example is basically the same as that of Example 1, except that the solid-liquid ratio of minced fish and water is 1:5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com