Silicon wafer batch polishing equipment

A technology for silicon wafers and equipment, which is applied in the field of batch polishing equipment for silicon wafers, can solve problems such as the inability to polish silicon wafers at the same time, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

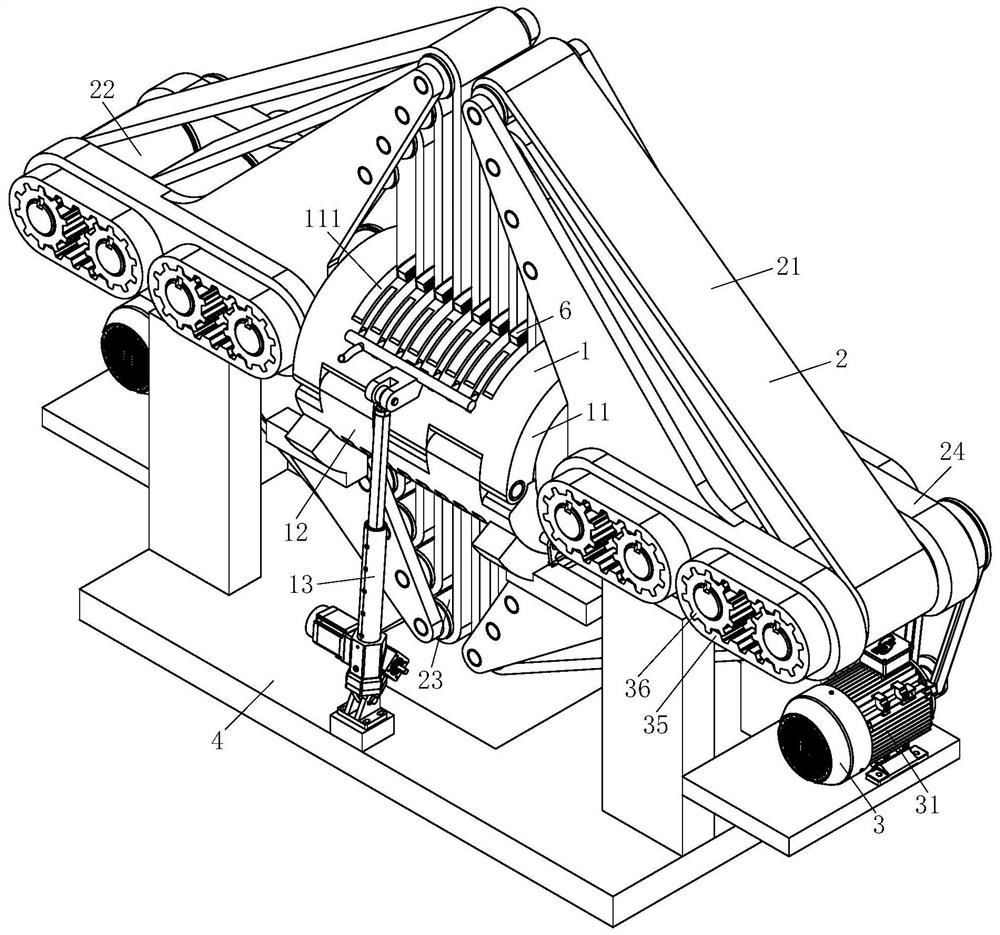

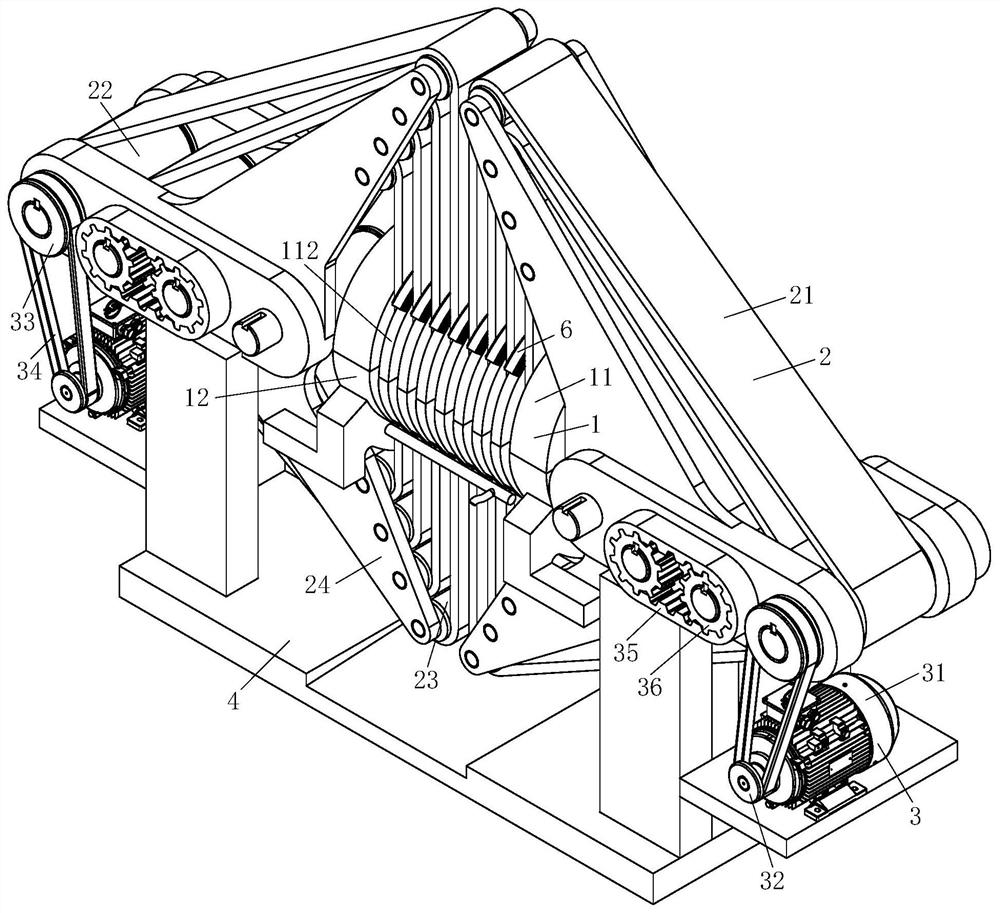

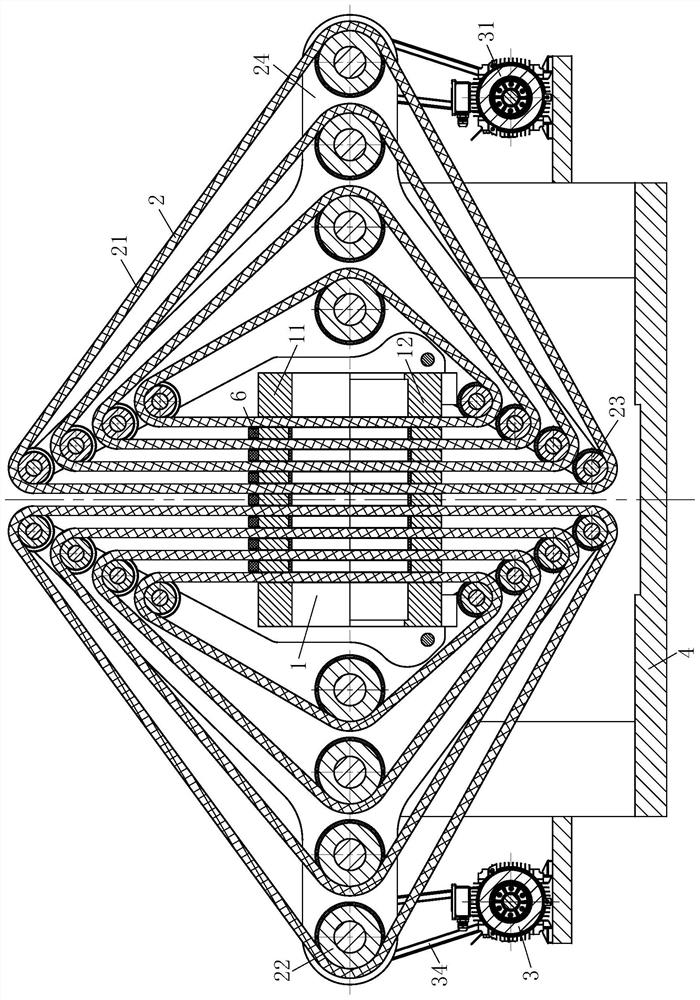

[0039] Such as Figure 1 to Figure 8 As shown, a batch polishing equipment for silicon wafers includes a clamping part 1, a polishing part 2, a power part 3 and a mounting frame 4; the clamping part 1 is arranged above the mounting frame 4; the clamping part 1 For clamping silicon wafers; the top of the mounting frame 4 is provided with a grinding part 2; the grinding part 2 is used to polish the surface of the silicon wafer; the mounting frame 4 is provided with the power part 3; The power unit 3 is used to provide power for the grinding unit 2;

[0040] The clamping part 1 includes an upper clamping body 11, a lower clamping body 12 and a No. 1 electric push rod 13; the upper clamping body 11 and the lower clamping body 12 are both semi-circula...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap