Method and device for recovering and purifying argon tail gas

A purification method and tail gas technology, applied in chemical instruments and methods, inert gas compounds, specific gas purification/separation, etc., can solve problems such as difficult recycling, environmental pollution, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

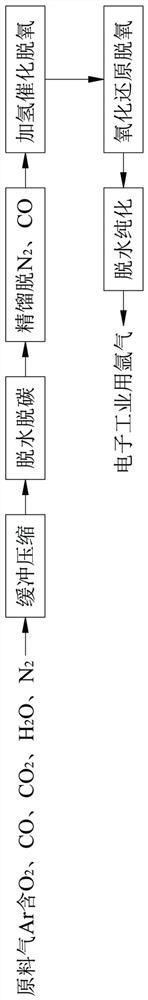

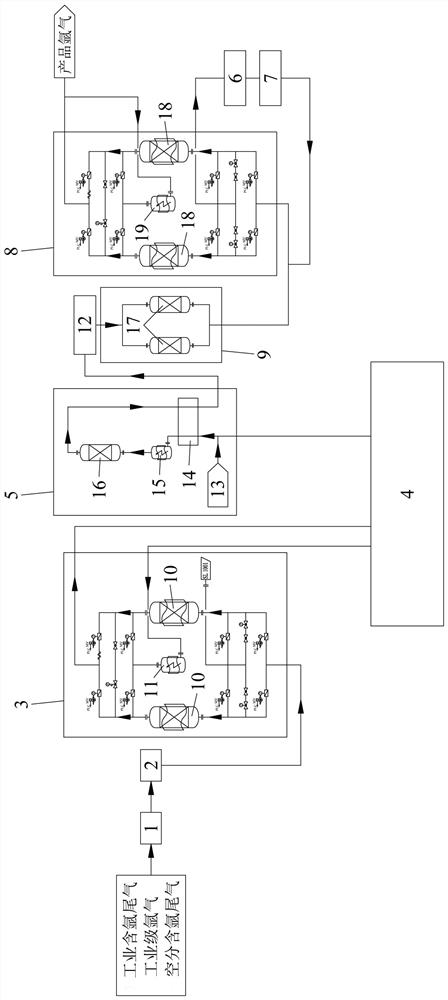

[0050] Example 1: An attached figure 1 As shown, the argon tail gas, the raw material gas to be recovered, except for argon, and a large amount of oxygen, carbon monoxide, carbon dioxide, water and nitrogen, the argon tail gas can be an industrial argon exhaust gas, industrial grade argon or space Argonically argon and the like. The recovery purity of the argon exhaust gas can be obtained by argon (conform to GB / 16945-2009), and the specific argon tail gas recovery method includes sequentially performing the following steps:

[0051] Step 1: Pretreatment of the argon tail gas to obtain a pretreatment of the particulate impurities and reaches the desired pressure and the desired temperature (buffer compression);

[0052] Step 2: Adsorbent by adsorbent to remove water and carbon dioxide in the gas after pretreatment to obtain purified gas (dehydrated);

[0053] Step 3: Distillation removes nitrogen gas and carbon monoxide in the purified gas to obtain rectification gas (rectificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com