Metal powder injection molding (MIM) production process for fragile tungsten-nickel-iron alloy material

A technology of tungsten-nickel-iron alloy and metal powder, which is applied in the field of MIM production process of brittle tungsten-nickel-iron alloy material metal powder injection molding. damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

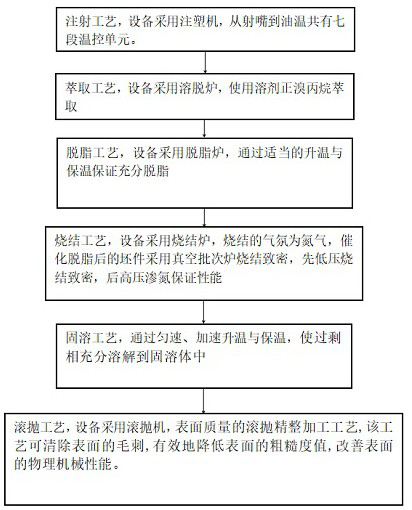

[0033] Fragile tungsten-nickel-iron alloy material metal powder injection molding MIM production process, injection process, extraction process, degreasing process, sintering process, solid solution process, rolling and throwing process, the proportion of each metal powder in the production process: tungsten accounts for 97% , The nickel component accounts for 1% to 1.5%, the iron component accounts for 1.5% to 2%, and the binder is a wax-based binder, of which paraffin wax accounts for about 80% and polyethylene accounts for about 20%.

specific Embodiment 3

[0035] Fragile tungsten-nickel-iron alloy material metal powder injection molding MIM production process, injection process, extraction process, degreasing process, sintering process, solid solution process, rolling and throwing process, the injection process adopts the general MIM wax-based system feeding injection process, of which injection The speed is 55±20, and the holding speed is 50±20.

specific Embodiment 4

[0037] Fragile tungsten-nickel-iron alloy material metal powder injection molding MIM production process, injection process, extraction process, degreasing process, sintering process, solid solution process, rolling and throwing process, the main component of the binder is removed in the extraction process. The binder is extracted with n-bromopropane as solvent to provide high-quality blanks for subsequent degreasing and sintering.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com