Steady flow area laser/ultrasonic composite low-damage complex microstructure machining device and method

A processing device and low-damage technology, which is applied in the field of laser/ultrasonic composite low-damage complex microstructure processing devices in the steady flow region, can solve the problems of difficulty in meeting the requirements of micro-processing, pollution, etc., and achieves the improvement of processed surface quality and subsurface. performance, improved execution accuracy, the effect of reduced disturbances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

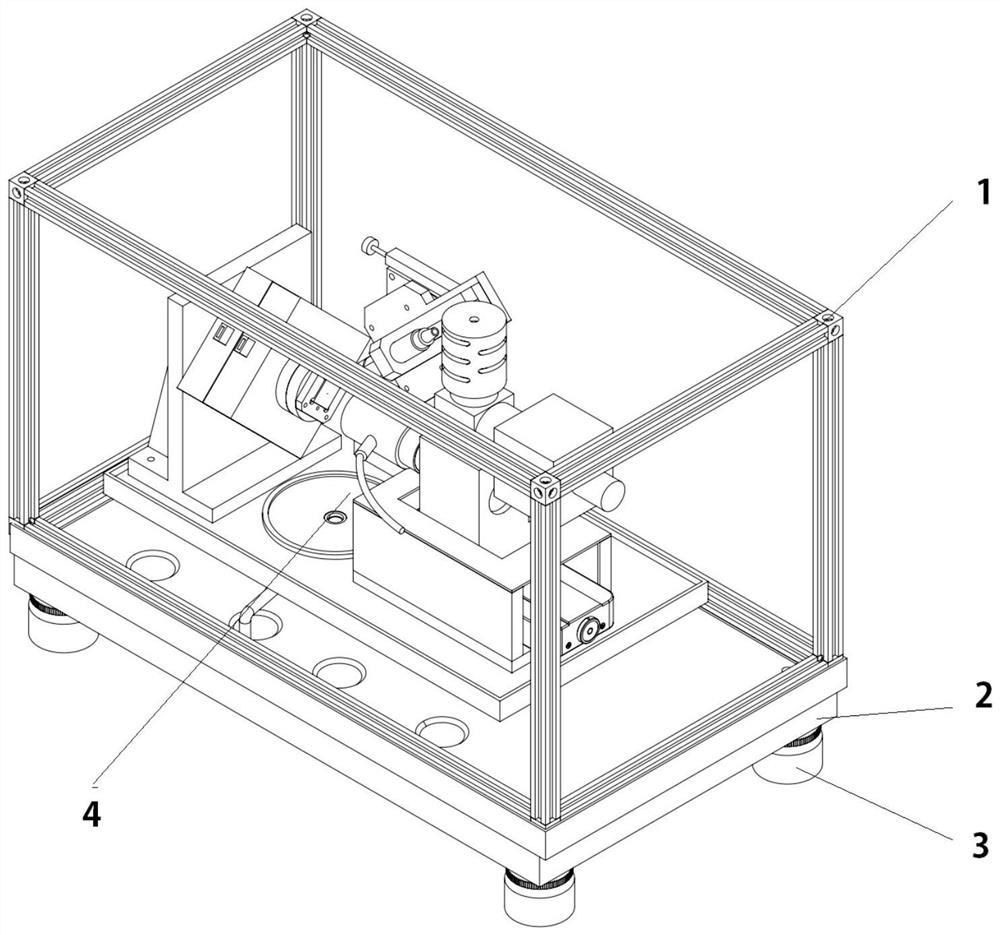

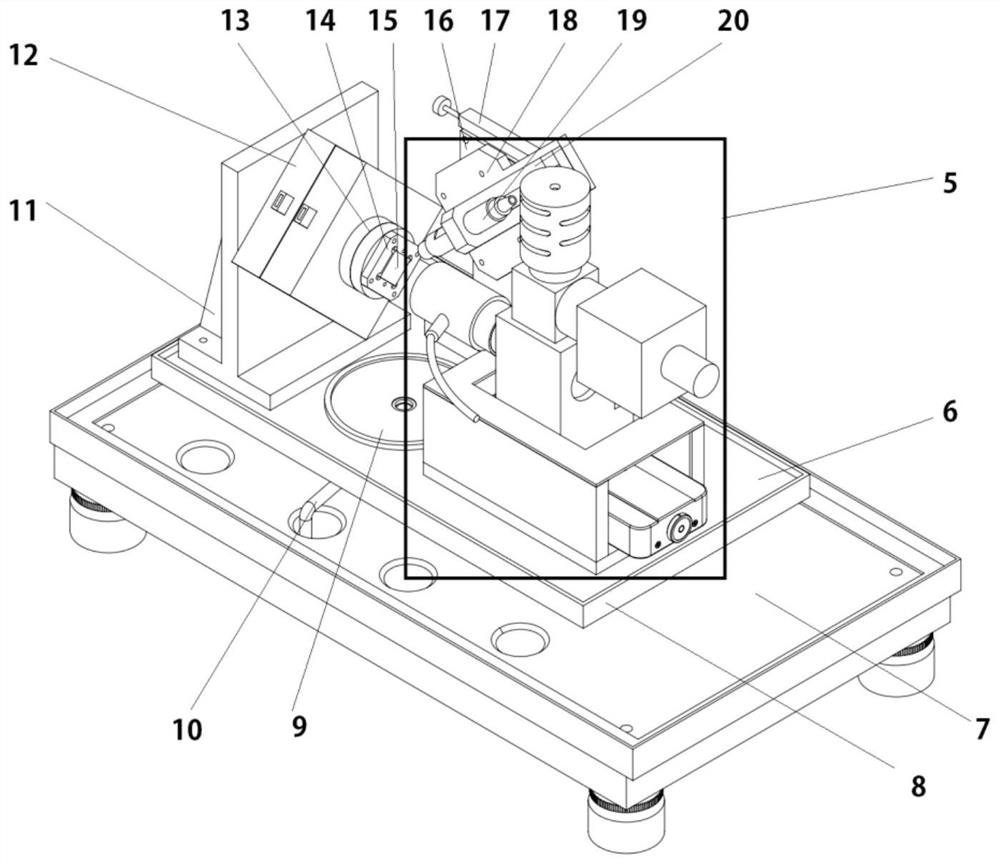

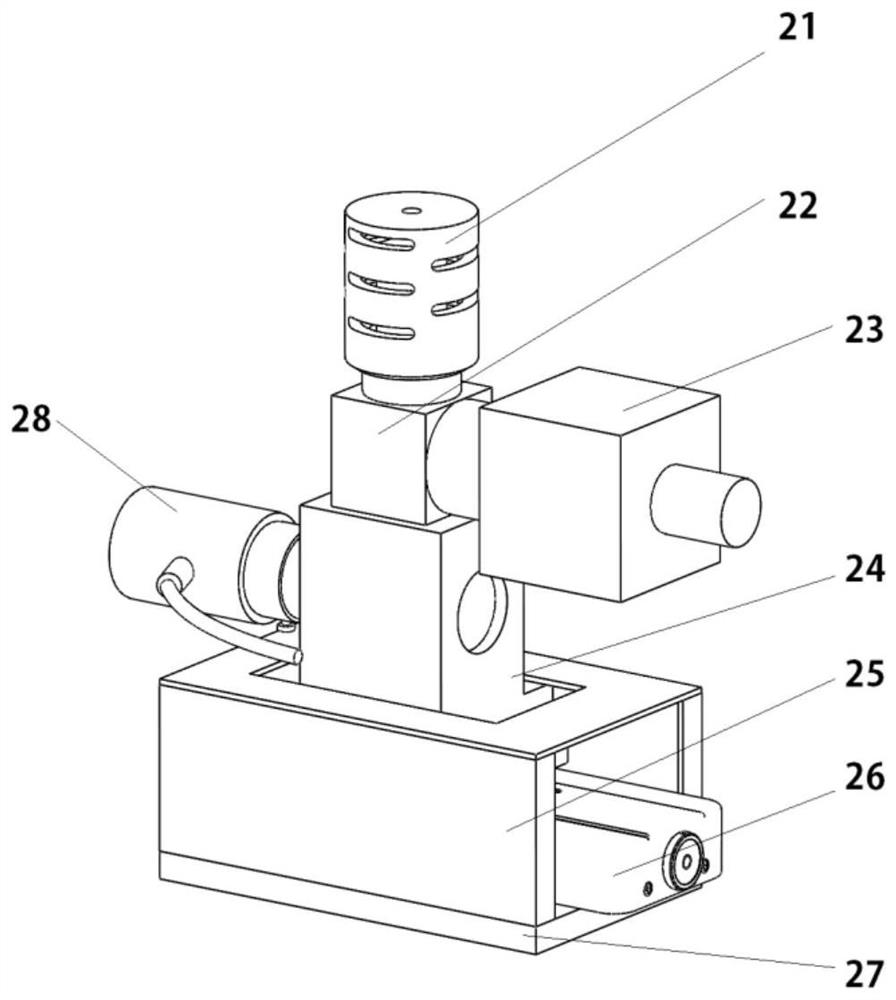

[0030] Such as figure 1As shown, the laser / ultrasonic composite low-damage complex microstructure processing device in the steady flow area includes: a base 2, a workpiece clamping slide unit 4, a laser unit 5, a jet gun unit and a host computer; the workpiece clamping slide The table unit 5, the laser unit 5 and the jet gun unit are all arranged on the base 2; below the workpiece clamping slide unit 5, a waste liquid tank 9 is arranged on the base 2; wherein the workpiece 15 is clamped On the workpiece clamping slide unit 5; in this embodiment, the material of the workpiece 15 is weak rigidity material. The optical axis of the laser light emitted by the laser unit 5 is in a horizontal state, perpendicular to the surface of the workpiece 15, and after the laser 23 finishes focusing during the processing, the light reflected by the mirror is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com