Forming method of small-size polyimide self-lubricating composite retainer material

A polyimide and molding method technology, applied in the field of cage preparation, can solve problems such as large human factors, material consistency needs to be improved, and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

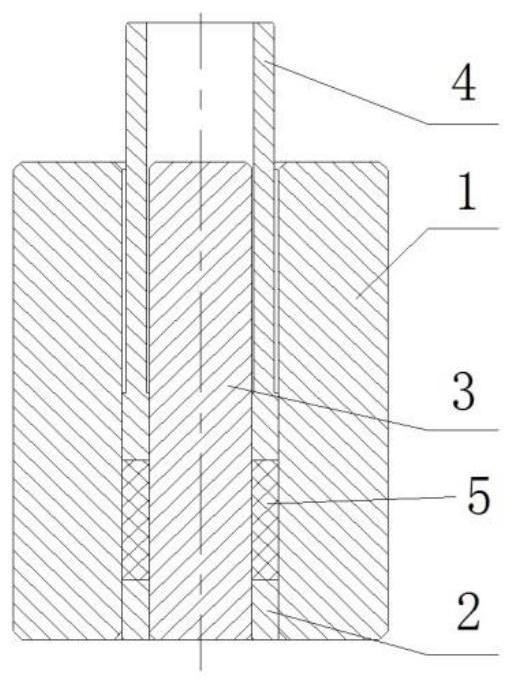

[0038] The molding method of the small-sized polyimide self-lubricating composite cage material in this embodiment uses such as Figure 2~3The six-unit solid mold includes cores (6), bases (6) and cavities (6), and the inner diameter of the cage is set to d=12mm, the outer diameter to D=14mm, and the height to H=3mm , the detailed molding process is as follows:

[0039] The first step: raw material pretreatment

[0040] Put the fusible ether anhydride type polyimide molding powder and molybdenum disulfide through 150-mesh sieve respectively in a vacuum drying oven for 2 hours, then take them out and cool them down and seal them separately. It is controlled at -0.08MPa, and the temperature of the vacuum drying oven is controlled at 150°C.

[0041] Put the polytetrafluoroethylene screened through 80 meshes in a vacuum drying oven for 2 hours, take it out, cool it and seal it for storage. The vacuum degree of the vacuum drying oven is controlled at -0.08MPa, and the temperature...

Embodiment 2

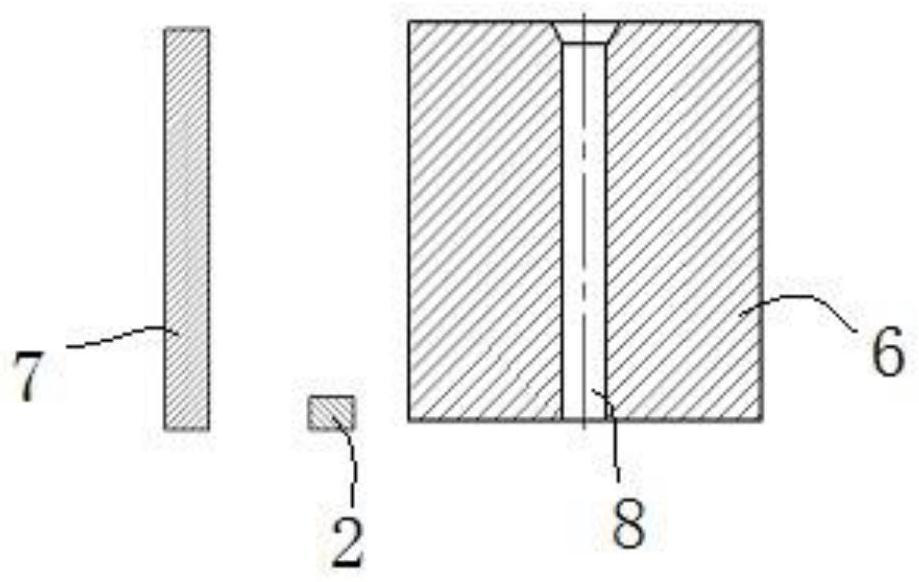

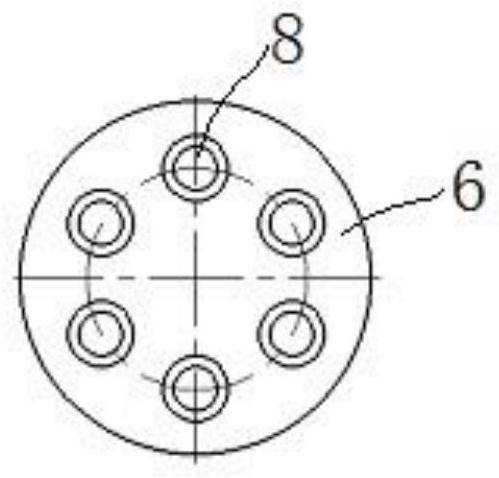

[0053] The molding method of the small-sized polyimide self-lubricating composite cage material in this embodiment uses Figure 4~5 The six-joint tubular material mold, with reference to the process parameters of Example 1, produced a tubular blank.

[0054] In other embodiments of the molding method of the small-sized polyimide self-lubricating composite cage material of the present invention, on the basis of Embodiment 1, the raw material composition of the molding cage material can be: meltable polyimide mold Plastic powder 85%, polytetrafluoroethylene 10%, molybdenum disulfide 5%, or fusible polyimide molding powder 75%, polytetrafluoroethylene 15%, molybdenum disulfide 10%.

[0055] The initial pressure condition can be 600kg / cm 2 Hold the pressure for 3 minutes, and the secondary pressing condition can be 1200kg / cm 2 Hold the pressure for 3 minutes, and the final pressure condition can be 1200kg / cm 2 Hold the pressure for 8 minutes.

[0056] The primary sintering and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com