Gypsum-based thermal insulation mortar and preparation method thereof

A thermal insulation slurry and gypsum-based technology, which is applied in the field of building materials, can solve the problems of poor thermal insulation, limited application range, and complicated construction steps, and achieve good thermal insulation performance, large volume, and volume stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

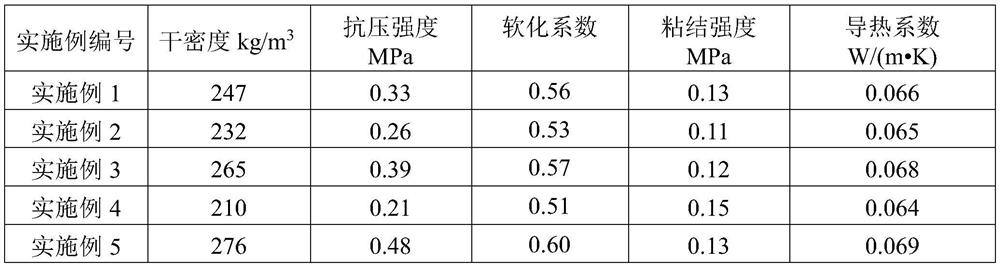

Examples

Embodiment 1

[0028] A gypsum-based thermal insulation slurry, the composition of each cube is: 75kg of hydrophobic modified expanded perlite, 250kg of gypsum-steel slag composite gel, 3kg of polycarboxylate high-performance water-reducing agent, 2kg of sodium citrate, silicone emulsion type Water repellent 3.5kg, carboxymethyl cellulose 3kg, water 142kg. The preparation method of the above-mentioned gypsum-based thermal insulation slurry comprises the following steps:

[0029] (1) Mix 75kg of water-enhanced modified expanded perlite with 250kg of gypsum-steel slag composite gel to obtain mixture A; wherein, the water-enhanced modified expanded perlite is expanded by hydrophobic modification of 2.36mm<particle size≤4.75mm Perlite, 1.80mm < particle size ≤ 2.36mm hydrophobic modified expanded perlite, particle size ≤ 1.80mm hydrophobic modified expanded perlite in a mass ratio of 4:1:5; gypsum-steel slag composite condensate The glue is prepared by mixing gypsum and steel slag uniformly acc...

Embodiment 2

[0033] A gypsum-based thermal insulation slurry, the composition of each cube is: 70kg of hydrophobic modified expanded perlite, 200kg of gypsum-steel slag composite gel, 2.5kg of polycarboxylate high-performance water reducing agent, 1.5kg of sodium tripolyphosphate, organic Silicone emulsion type waterproofing agent 1.5kg, carboxypropyl cellulose 2kg, water 135kg. The preparation method of the above-mentioned gypsum-based thermal insulation slurry comprises the following steps:

[0034] (1) Mix 70kg of water-enhanced modified expanded perlite with 200kg of gypsum-steel slag composite gel to obtain mixture A; wherein, the water-enhanced modified expanded perlite is expanded by hydrophobic modification of 2.36mm<particle size≤4.75mm Perlite, 1.80mm < particle size ≤ 2.36mm hydrophobic modified expanded perlite, particle size ≤ 1.80mm hydrophobic modified expanded perlite in a mass ratio of 2:2.5:5.5; gypsum-steel slag composite condensate The glue is prepared by mixing gypsum...

Embodiment 3

[0038] A gypsum-based thermal insulation slurry, the composition of each cube is: 80kg of hydrophobic modified expanded perlite, 300kg of gypsum-steel slag composite gel, 4kg of polycarboxylate high-performance water-reducing agent, 3kg of sodium polyphosphate, and silicone emulsion Type waterproofing agent 5kg, methyl cellulose 4kg, water 150kg. The preparation method of the above-mentioned gypsum-based thermal insulation slurry comprises the following steps:

[0039] (1) Mix 80kg of water-enhanced modified expanded perlite with 300kg of gypsum-steel slag composite gel to obtain mixture A; wherein, the water-enhanced modified expanded perlite is expanded by hydrophobic modification of 2.36mm<particle size≤4.75mm Perlite, 1.80mm < particle size ≤ 2.36mm hydrophobic modified expanded perlite, particle size ≤ 1.80mm hydrophobic modified expanded perlite with a mass ratio of 3.5:1.5:5; gypsum-steel slag composite condensate The glue is prepared by mixing gypsum and steel slag ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com