A hydrogel ink, a direct writing 3D printing ionic conductive hydrogel

A conductive hydrogel and 3D printing technology, applied in the field of hydrogels, can solve the problems of unsatisfactory mechanical properties of ion conductive hydrogels, unsatisfactory mechanical properties, and hindering practical applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] In the present invention, the preparation method of the hydrogel ink preferably comprises the following steps:

[0044] (1) heating and mixing polyvinyl alcohol with water to obtain an aqueous solution of polyvinyl alcohol;

[0045] (2) Chitosan and polyvinyl alcohol aqueous solution are ball-milled and mixed, and then acrylamide is added to the ball-milled mixed solution to obtain a premixed solution;

[0046](3) Mix the premixed solution with a photoinitiator and a crosslinking agent at 5-20° C. under light-shielded conditions to obtain a hydrogel ink.

[0047] The invention heats and mixes polyvinyl alcohol and water to obtain polyvinyl alcohol aqueous solution. In the present invention, the heating and mixing temperature is preferably 100° C.; in the present invention, the heating and mixing is preferably performed under stirring conditions, and the stirring rate is preferably 500-1000 rpm, more preferably 600-800 rpm. In the present invention, the polyvinyl alcoh...

Embodiment 1

[0063] (1) Take 3.22g of polyvinyl alcohol with a number average molecular weight of 89000-90000 and mix it with 26.78g of deionized water, and stir it mechanically at 100°C to obtain 30g of a polyvinyl alcohol aqueous solution with a mass concentration of 12%;

[0064] (2) Mix 3.75g chitosan with the above-mentioned polyvinyl alcohol aqueous solution by ball milling, the rotating speed of the ball milling is 1500rpm, and the time is 6min, add 6g acrylamide to the ball milling dispersion, and vigorously stir mechanically at 60°C to make it evenly dispersed , prepare the premixed solution;

[0065] (3) Add 0.1 g of photoinitiator α-ketoglutaric acid and 0.1 mL of cross-linking agent MBAA solution with a concentration of 10 mg / mL to the premixed solution, mechanically stir and mix evenly at 15° C. under light-shielding conditions, get hydrogel ink;

[0066] (4) The obtained hydrogel ink is placed in a centrifuge, and centrifuged at 8000rpm for 5min to remove air bubbles;

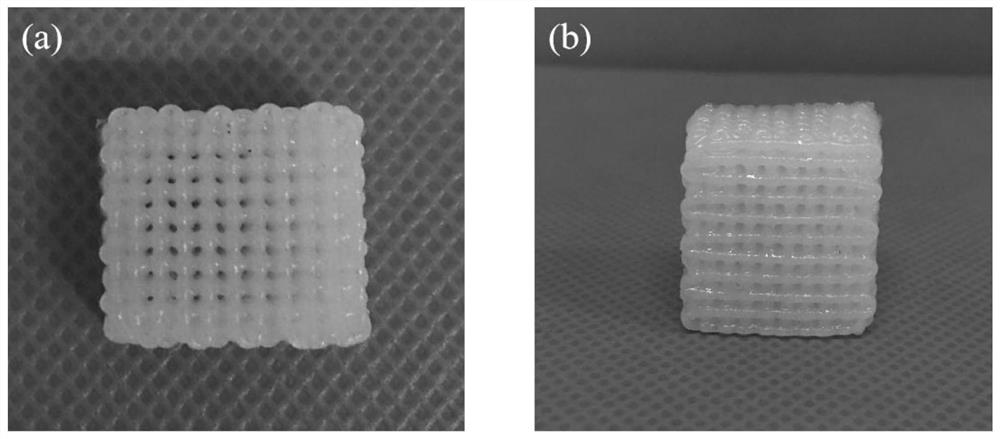

[00...

Embodiment 2

[0072] (1) Take 3.22g of polyvinyl alcohol with a number average molecular weight of 89000-90000 and mix it with 26.78g of deionized water, and stir it mechanically at 100°C to obtain 30g of a polyvinyl alcohol aqueous solution with a mass concentration of 12%;

[0073] (2) Mix 4.5g of chitosan with the above-mentioned polyvinyl alcohol aqueous solution by ball milling, the rotating speed of the ball milling is 1500rpm, and the time is 6min, add 6g of acrylamide to the ball milling dispersion, and vigorously stir mechanically at 60°C to make it evenly dispersed , prepare the premixed solution;

[0074] (3) Add 0.0015g of photoinitiator α-ketoglutaric acid and 0.1mL of cross-linking agent MBAA solution with a concentration of 10mg / mL to the premixed solution, mechanically stir and mix evenly at 10°C and in the dark, get hydrogel ink;

[0075] (4) The obtained hydrogel ink is placed in a centrifuge, and centrifuged at 7000rpm for 5min to remove air bubbles;

[0076] (5) Inject...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

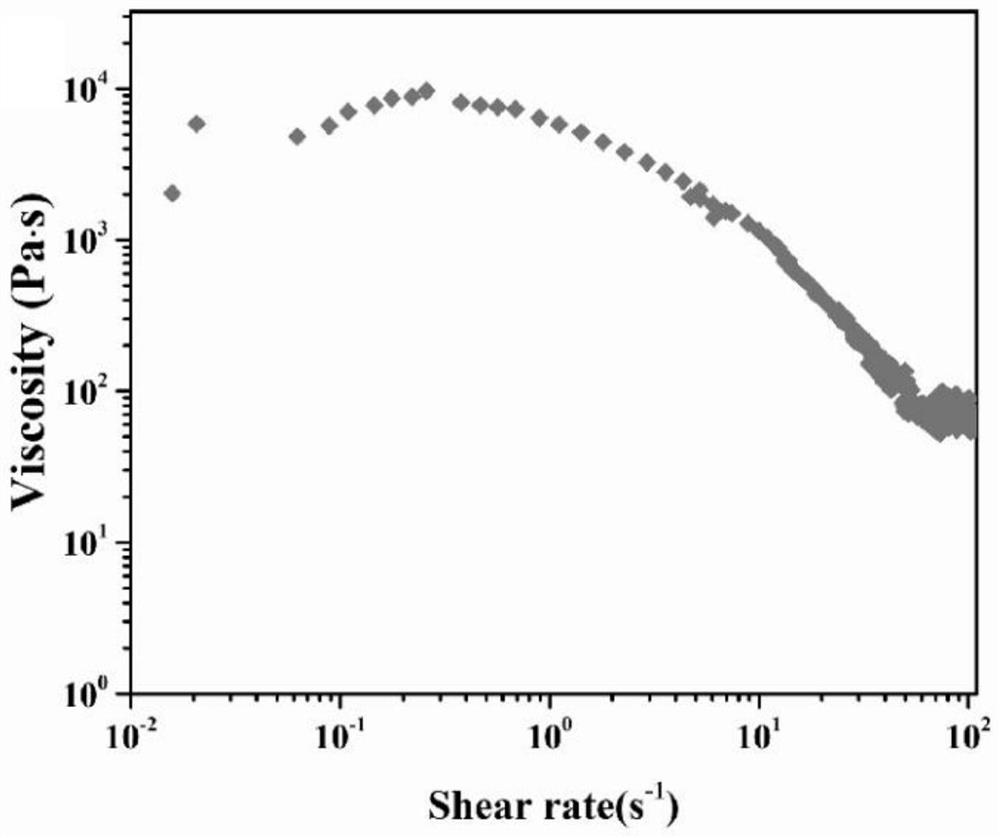

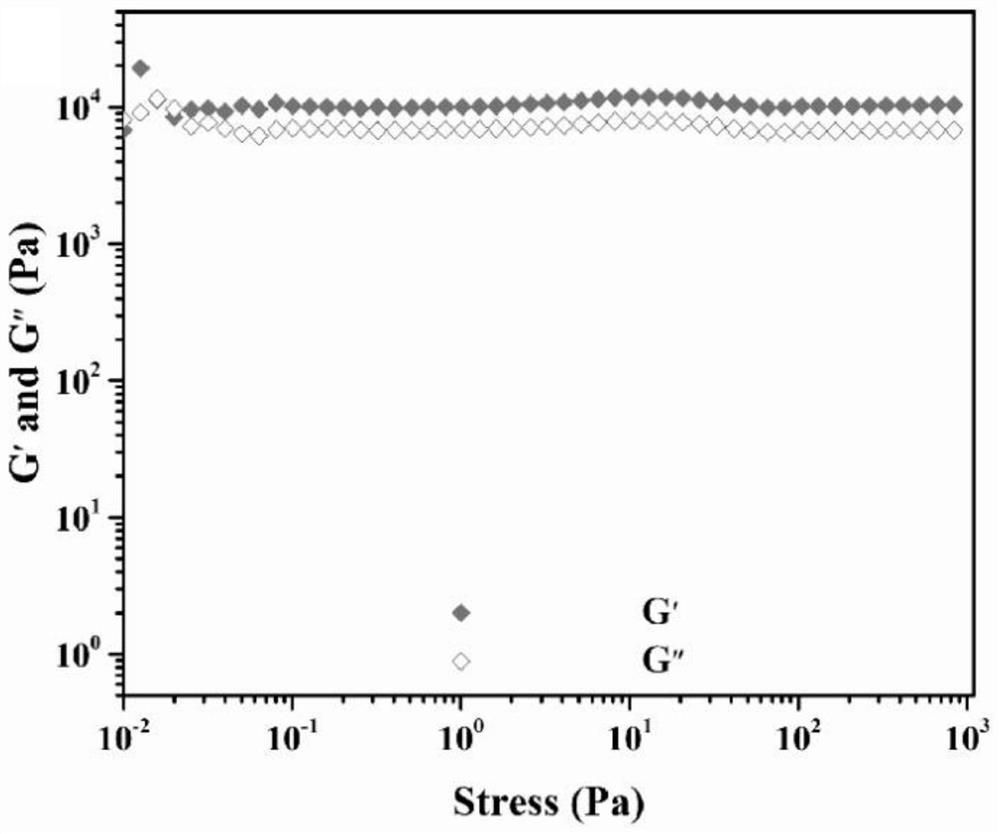

| viscosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com