Preparation method of antibacterial color master batch

A technology of antibacterial color and masterbatch, applied in the field of preparation of antibacterial color masterbatch, can solve the problems of unusable, unfavorable granulation, and no bacteriostatic and bactericidal effect of color masterbatch, so as to ensure the cutting effect and prolong the residence time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Such as figure 1 As shown, an antibacterial color masterbatch, the antibacterial color masterbatch is composed of the following parts by weight: 15-25 parts of silver-loaded silica gel, 25-32 parts of colorant, 1.2-2.5 parts of benzotriazole derivatives , 1.2-1.8 parts of titanate coupling agent, 1.6-3.5 parts of ethylene bis stearic acid amide, 1.5-2.4 parts of 2-phenylene moiety and 78.5-88.6 parts of linear low density polyethylene.

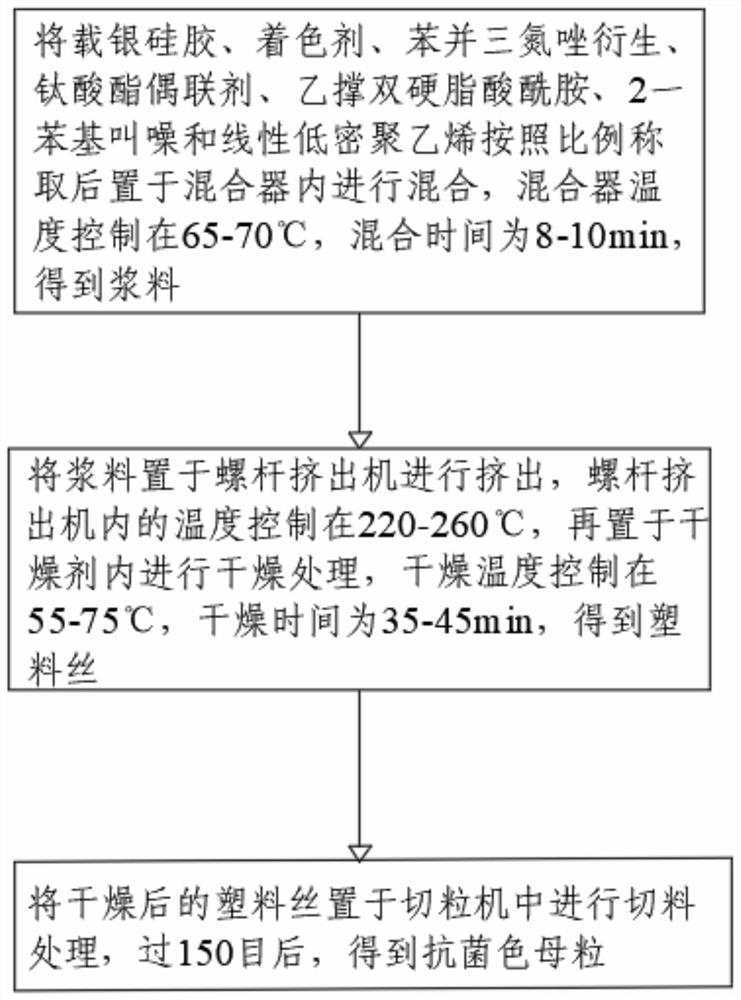

[0045] A preparation method of antibacterial color masterbatch, the preparation method steps are as follows:

[0046] Step 1. Weigh the silver-loaded silica gel, colorant, benzotriazole derivative, titanate coupling agent, ethylene bisstearic acid amide, 2-phenylene moiety and linear low-density polyethylene according to the proportion Then put it in a mixer for mixing, the temperature of the mixer is controlled at 65-70°C, and the mixing time is 8-10min to obtain a slurry;

[0047] Step 2. Put the slurry in a screw extruder for extru...

Embodiment 2

[0051] Embodiment 2 is a further improvement to Embodiment 1.

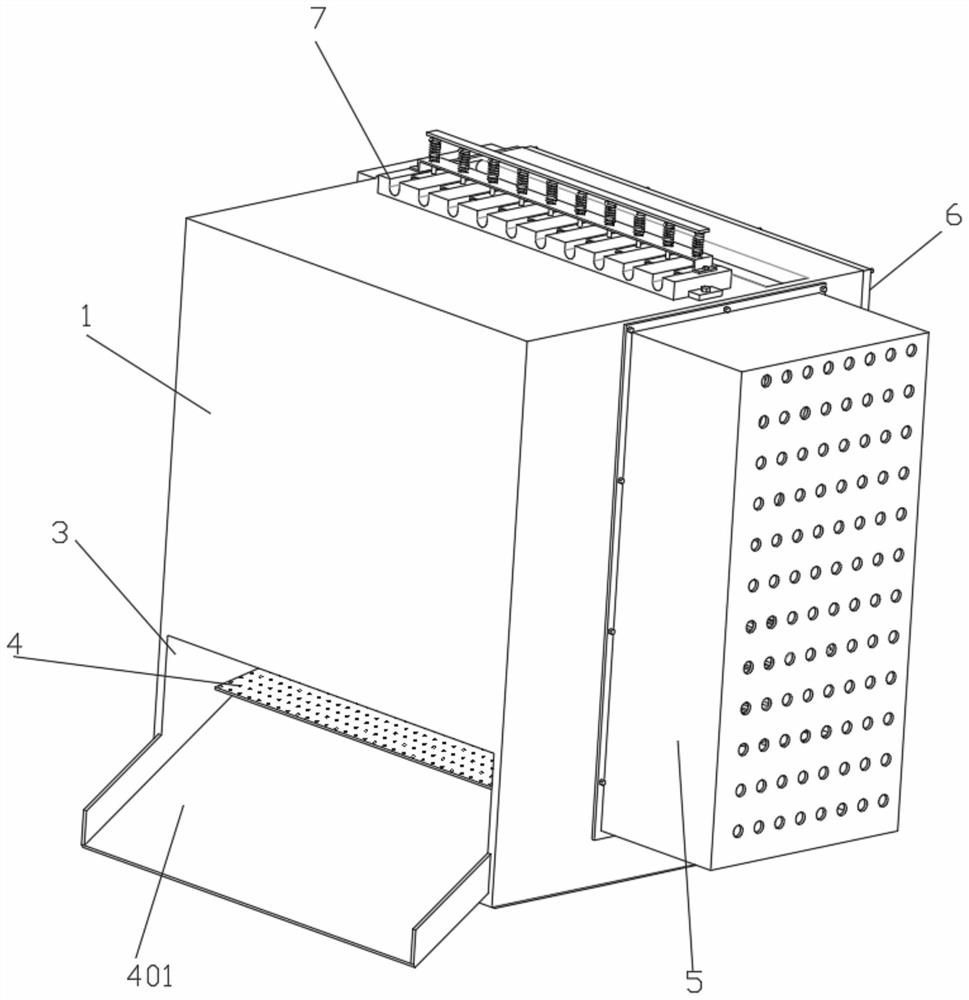

[0052] Based on the above formula and process, the present invention also provides a preparation device for antibacterial color masterbatch, such as figure 2 , 3 , 4, 5, 6, 8, 9, and 11 show a preparation device for antibacterial color masterbatches, comprising a pelletizing box 1, the rear side wall of the pelletizing box 1 is fixedly connected with a rear panel 6 by bolts, and the pelletizing The top of the box 1 is provided with a straight hole 9, and the top of the pelletizing box 1 is connected with a guide wire structure 7 for guiding materials in sequence. The guide wire structure 7 includes a bottom plate 701, a slide bar 702, a spring 703, and a lifter. 704, an n-shaped plate 705, an arc-shaped pressing plate 706, an arc-shaped groove 707, and the fourth projection 708, the fourth projection 708 is fixedly connected with a base plate 701, and the top of the base plate 701 is evenly fixedly connected wit...

Embodiment 3

[0056] Embodiment 3 is a further improvement to Embodiment 1.

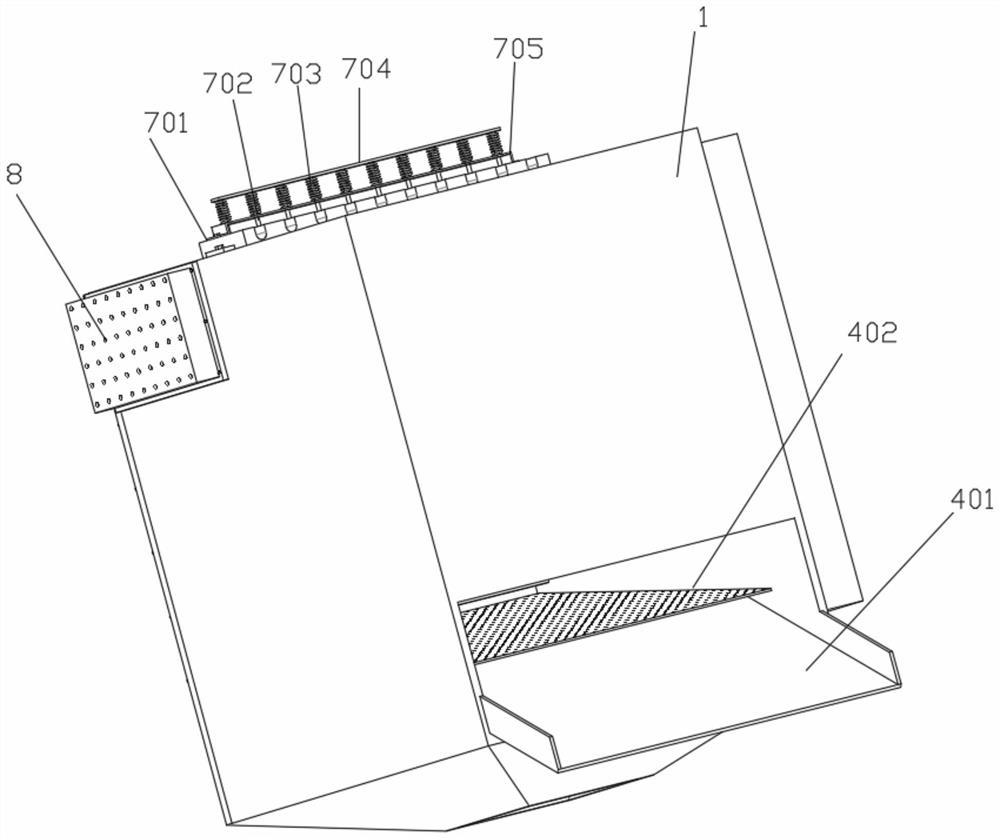

[0057] Such as image 3 , 7 , 8, 9, and 10, the front side wall of the pelletizing box 1 is provided with a discharge hole 3, and the pelletizing box 1 is provided with a screening structure 4 for vigorous screening at the bottom of the pelletizing roller 10, and the screening structure 4 Including U-shaped bucket 401, filter plate 402, first belt 403, first pulley 404, first shaft 405, first bump 406, second pulley 407, second bump 408, third bump 409 and inverted L shaped plate 410, the inner wall of the rear panel 6 is evenly fixedly connected with the third projection 409, the third projection 409 is connected with the second projection 408 through the rotating shaft fixedly connected, and the second projection 408 is fixedly connected with the The filter plate 402, the top of the filter plate 402 is provided with an inverted L-shaped plate 410 for collecting materials, the second pulley 407 is fixedly insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com