Polarization maintaining hollow-core anti-resonance optical fiber

A polarization-maintaining and anti-resonance technology, applied in the direction of polarized optical fiber, clad optical fiber, light guide, etc., can solve the problems of polarization mode dispersion and affecting the functional stability of optical devices, and achieve high polarization extinction ratio, obvious effect of high-order mode leakage, and polarization Maintain good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Taking the working wavelength of 1550nm as an example, the inventive principle is also applicable to each wavelength.

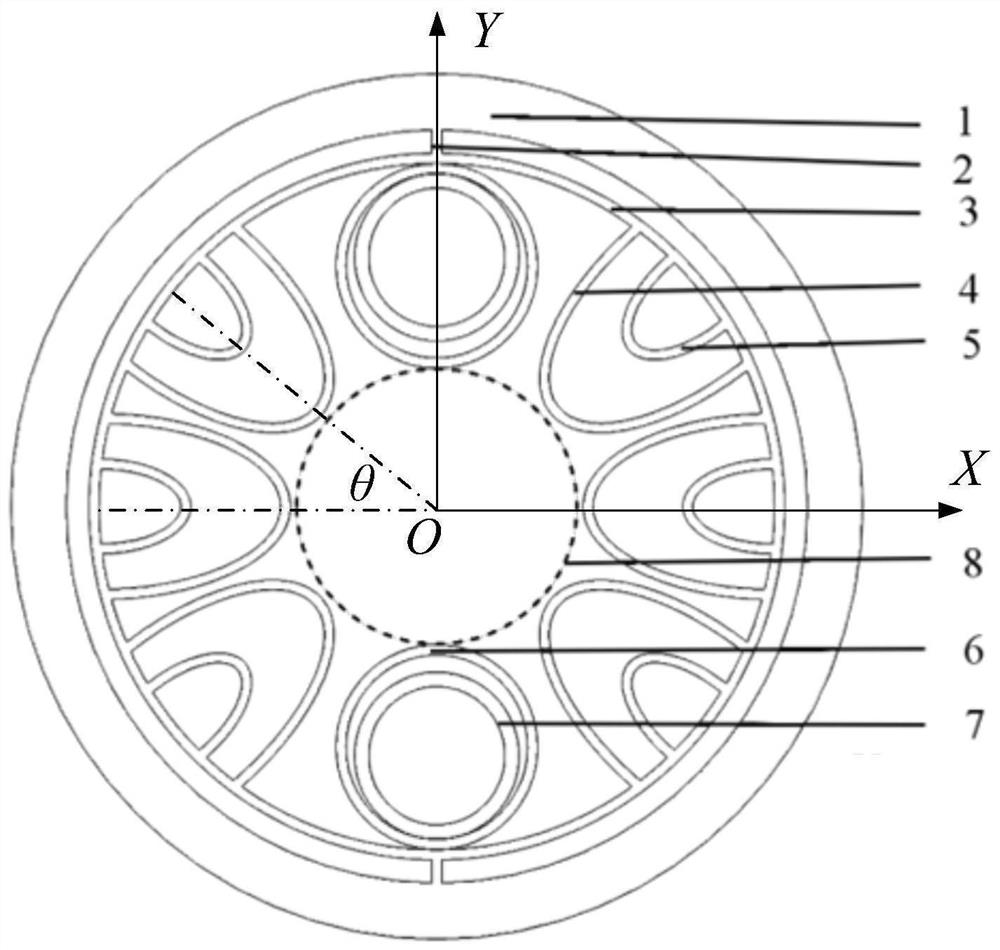

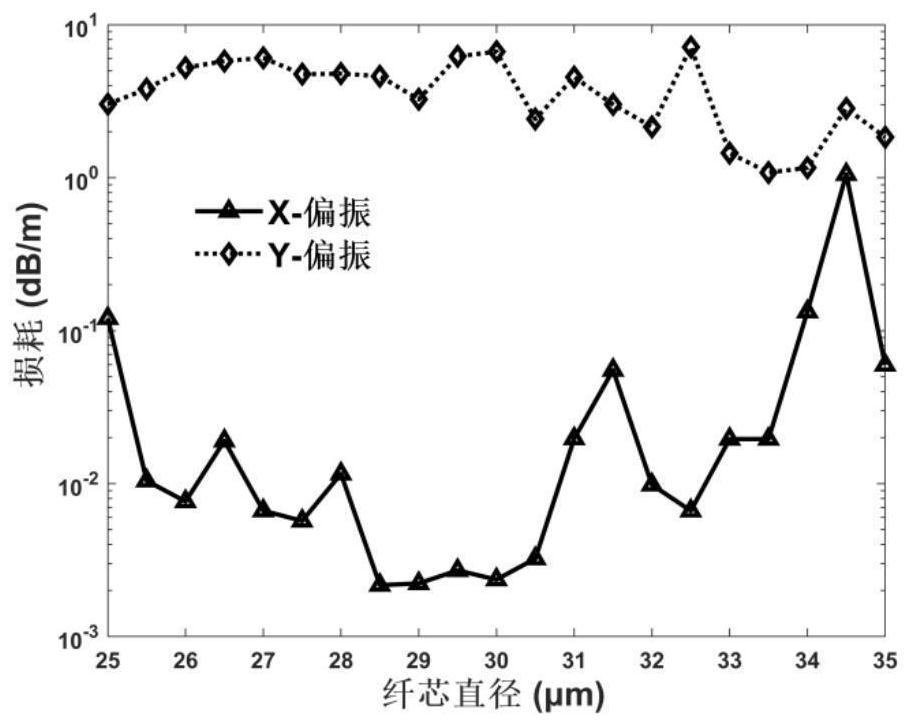

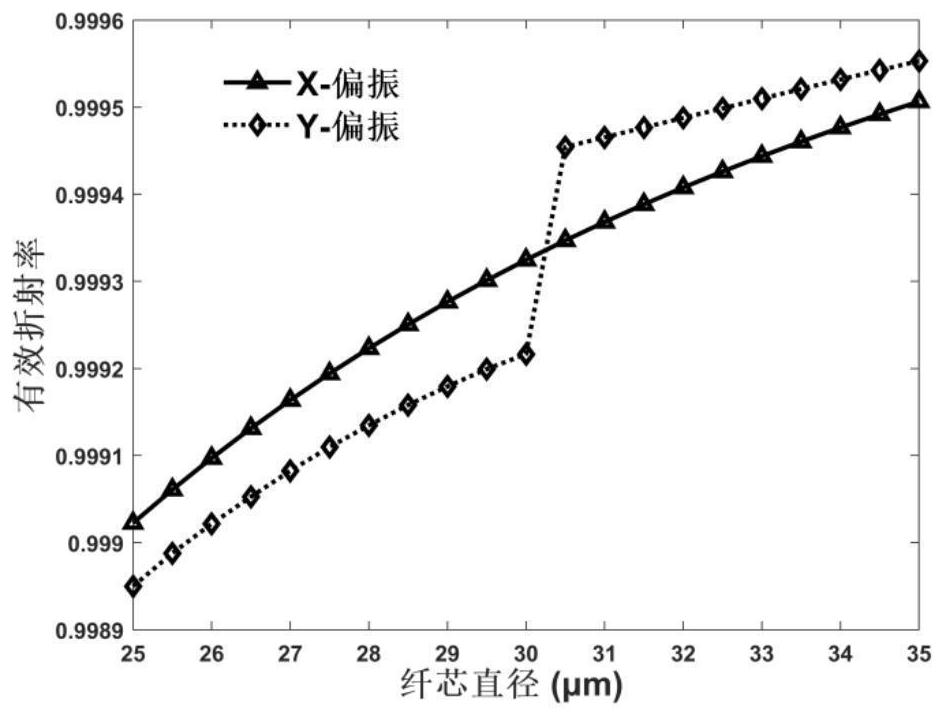

[0038] Such as figure 1 shown, calculated using finite element simulation figure 1 For the structure shown, the relevant parameters of the polarization-maintaining hollow-core anti-resonant fiber are as follows: the length of the connecting tube is 2.5 μm, the inner diameter of the cladding ring is 71.5 μm; the outer diameter of the outer cladding is 88 μm; the inner diameter of the circular cladding tube 6 and the semi-elliptical cladding tube 4 The inner diameter of the major axis: 20 μm; the inner diameter of the semi-elliptic nesting tube 5 is 9 μm; the inner diameter of the circular nesting tube 7 is 15 μm; the connecting tube 2, the cladding ring 3, the semi-elliptical cladding tube 4, and the semi-elliptical nesting tube 5. The wall thickness of the circular cladding tube 6 is 0.375 μm; the wall thickness of the circular nesting tube 7 is 1.58 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com