Continuous manufacturing system of conductive connecting layer

A technology of conductive connection and metal wire, applied in the field of continuous production system, can solve the problems of poor welding of conductive connection layer, unsatisfactory yield strength, complicated production process, etc., to achieve the effect of efficient continuous production, lower yield strength, and reduced turnover process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

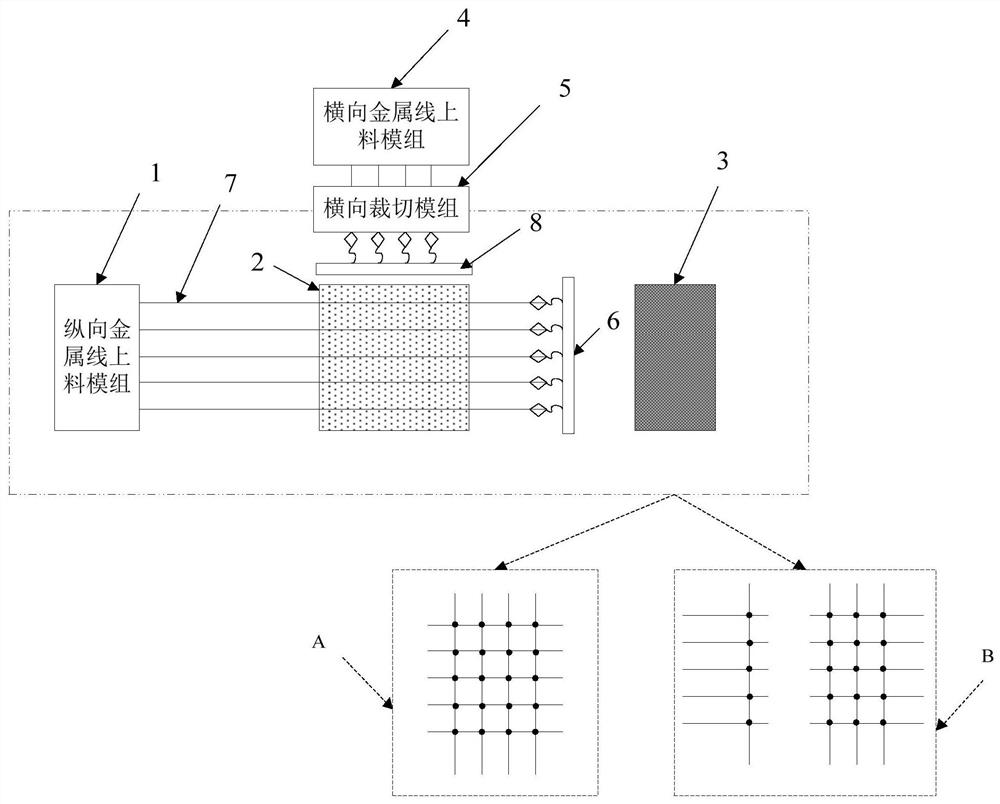

[0035] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

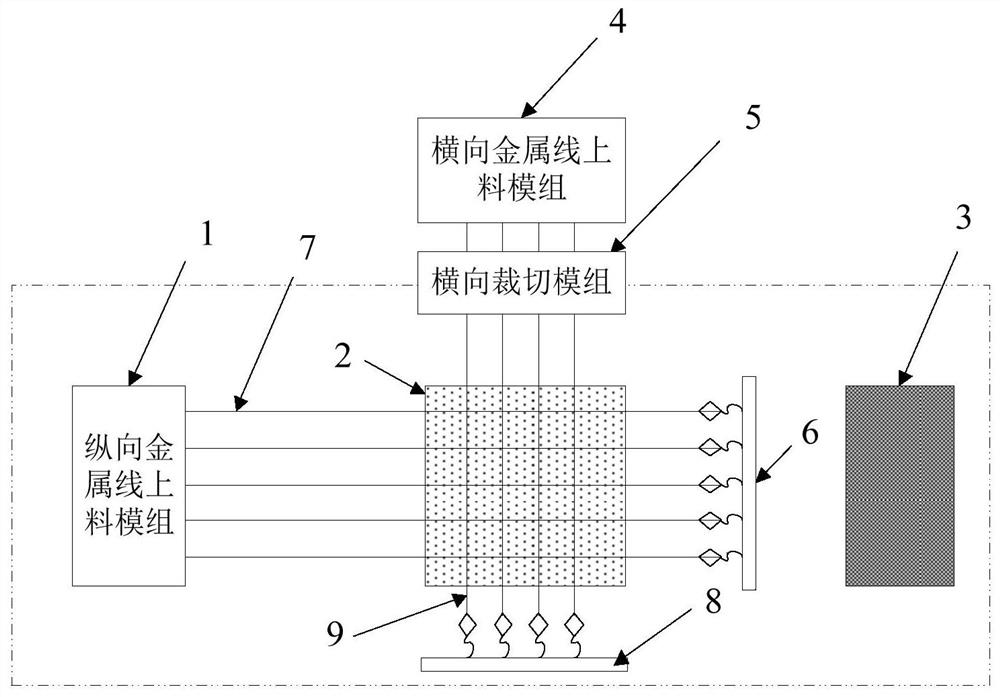

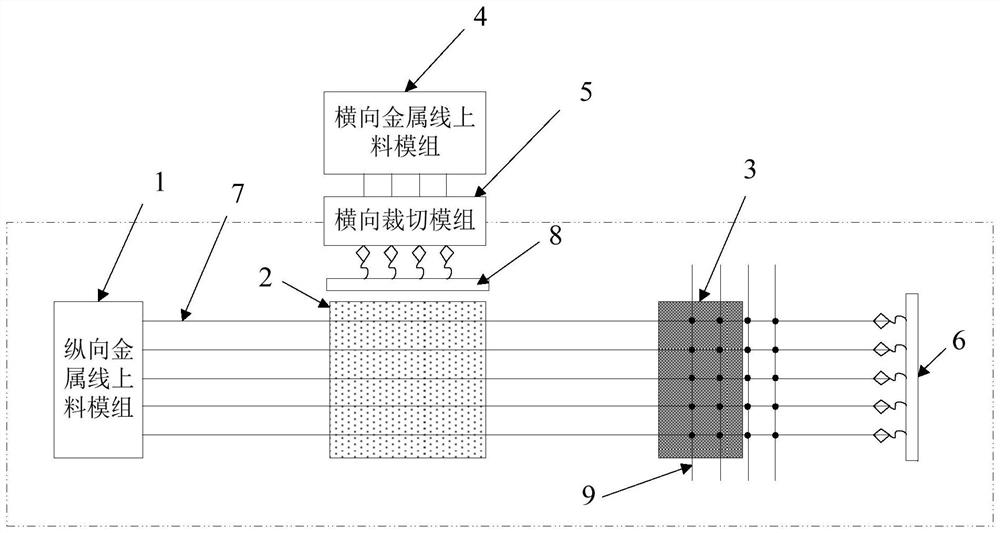

[0036] The present application discloses a continuous production system of a conductive connection layer, the system includes a longitudinal metal wire feeding module 1, a welding module 2 and a longitudinal cutting module 3 arranged sequentially along the first direction from front to back. In the processing line, the transverse metal wire feeding module 4 is arranged beside the processing line at the welding module 2 , and the transverse cutting module 5 is arranged between the transverse metal wire feeding module 4 and the welding module 2 .

[0037] The longitudinal metal wire pulling module 6 moves toward the direction of the longitudinal cutting module 3 and pulls out N longitudinal metal wires 7 along the first direction from the longitudinal metal wire feeding module 1, such as figure 1 Take N=5 as an example.

[0038] When the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com