Vanadium-doped three-dimensional mesoporous Co3O4 nano-catalyst as well as preparation method and application thereof

A nano-catalyst and three-dimensional mesoporous technology, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of oxygen reduction and oxygen evolution reaction catalytic performance to be improved, and achieve excellent dual functions The effect of oxygen catalytic activity, simple reaction conditions, and less synthesis equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

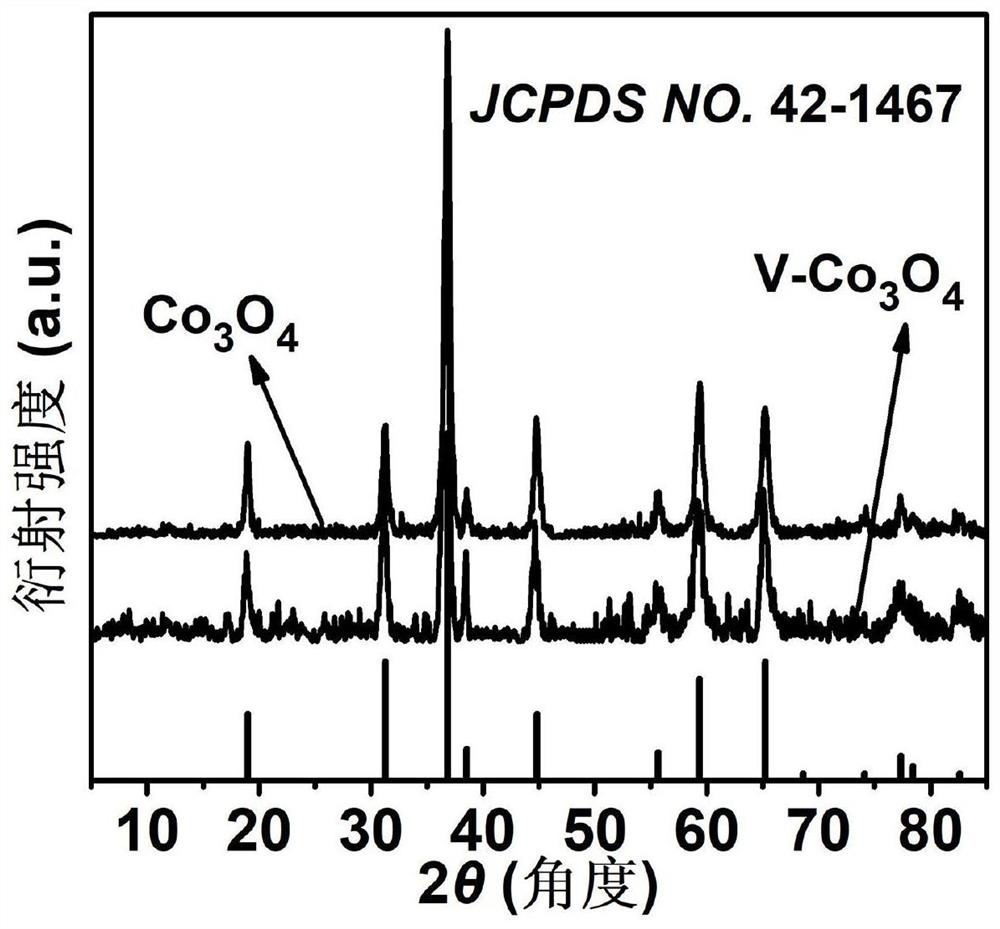

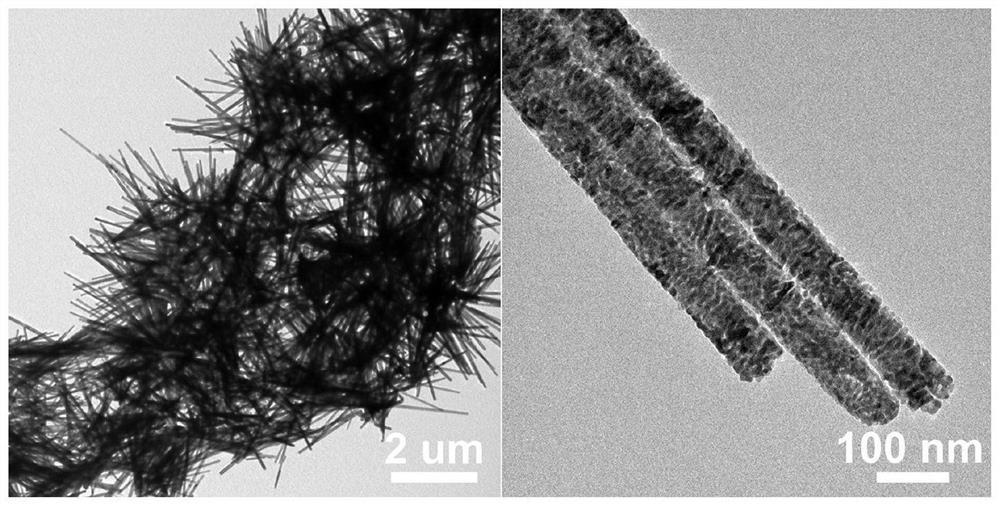

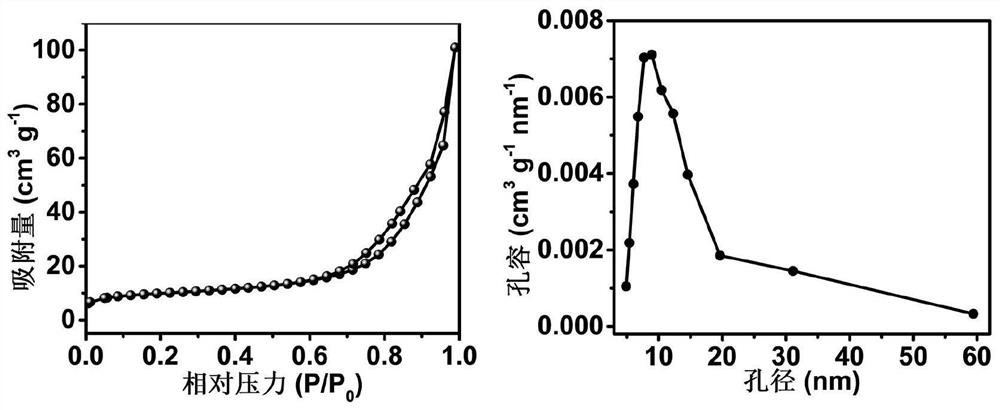

[0035] A vanadium-doped three-dimensional mesoporous Co 3 o 4 Nanorod, its preparation method is as follows:

[0036] (1) Evenly disperse 0.75 mmol of cobalt dichloride hexahydrate and 0.25 mmol of vanadium trichloride in 27 mL of ultrapure water, add 3 mL of glycerin dropwise, transfer to a 50 mL reaction kettle, and react in a blast oven at 200°C for 24 hours.

[0037] (2) After the hydrothermal kettle is naturally cooled to room temperature, the solid product is centrifuged, washed three times with ultrapure water, dried, and calcined at 250°C for 1 hour at a heating rate of 5°C / min in a muffle furnace to obtain vanadium-doped Heterogeneous three-dimensional mesoporous Co 3 o 4 Nano stave.

Embodiment 2

[0039] A vanadium-doped three-dimensional mesoporous Co 3 o 4 Nanorod, its preparation method is as follows:

[0040] (1) Evenly disperse 0.6 mmol of cobalt dichloride hexahydrate and 0.2 mmol of vanadium trichloride in 27 mL of ultrapure water, add dropwise 3 mL of glycerin, transfer to a 50 mL reaction kettle, and react in a blast oven at a constant temperature of 180°C for 24 hours.

[0041] (2) After the hydrothermal kettle is naturally cooled to room temperature, the solid product is centrifuged, washed three times with ultrapure water, dried, and calcined at 300°C for 1 hour at a heating rate of 5°C / min in a muffle furnace to obtain vanadium-doped Heterogeneous three-dimensional mesoporous Co 3 o 4 Nano stave.

Embodiment 3

[0043] A vanadium-doped three-dimensional mesoporous Co 3 o 4 Nanorod, its preparation method is as follows:

[0044] (1) Evenly disperse 0.55 mmol of cobalt dichloride hexahydrate and 0.25 mmol of vanadium trichloride in 27 mL of ultrapure water, add dropwise 3 mL of glycerin, transfer to a 50 mL reaction kettle, and react in a blast oven at 200°C for 24 hours.

[0045] (2) After the hydrothermal kettle is naturally cooled to room temperature, the solid product is centrifuged, washed three times with ultrapure water, dried, and calcined at 280°C for 1 hour at a heating rate of 5°C / min in a muffle furnace to obtain vanadium-doped Heterogeneous three-dimensional mesoporous Co 3 o 4 Nano stave.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com