Device and process for producing dilute nitric acid by magnesium nitrate method

A technology of magnesium nitrate and dilute nitric acid, which is applied in the field of dilute nitric acid production, can solve the problems that the concentration change cannot be greatly adjusted, the utilization rate of equipment is low, and the process route is difficult to make large changes and adjustments, etc., and the preparation method is simple and the cost is low. Reduce, the effect that preparation method is easy to popularize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

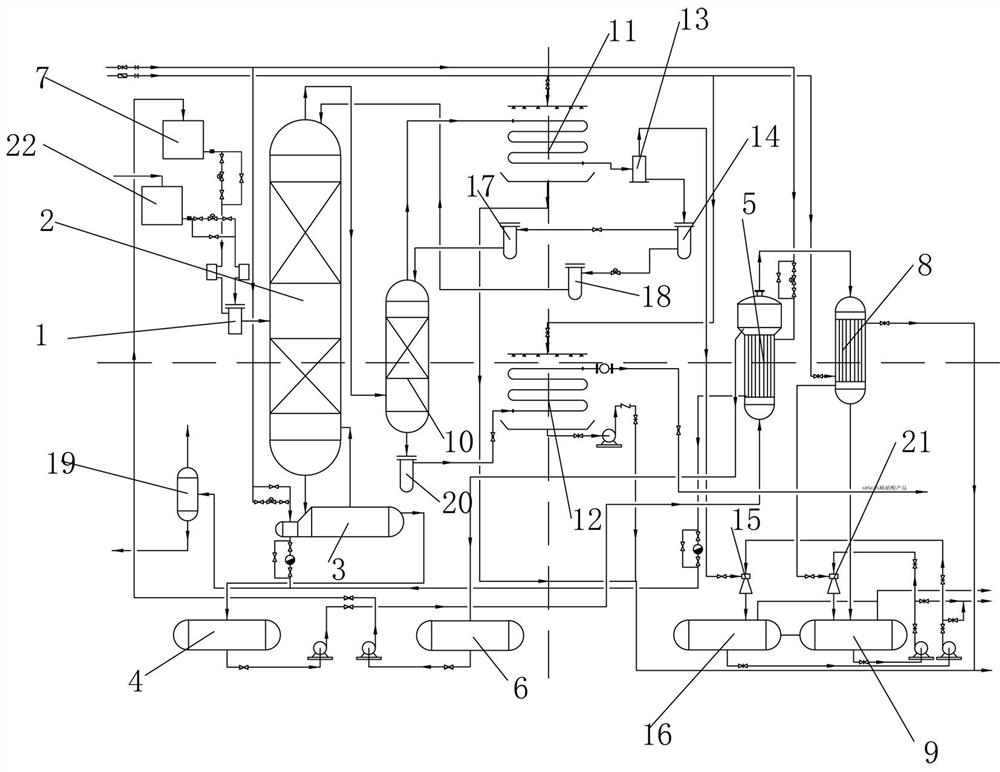

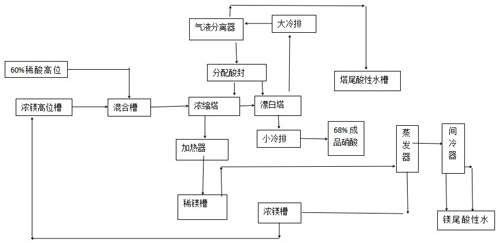

[0024] As shown in the figure, a device for producing dilute nitric acid by magnesium nitrate method includes a raw material mixing distributor 1, a nitric acid concentration tower 2 connected to the outlet of the raw material mixing distributor 1, and the bottom of the nitric acid concentration tower 2 is connected with a magnesium nitrate heater 3 3 outlets of the magnesium nitrate heater are connected with the dilute magnesium nitrate tank 4, and the dilute magnesium nitrate tank 4 sends the material to the magnesium nitrate evaporator 5 for further processing by the dilute magnesium nitrate pump, and the liquid collected by the magnesium nitrate evaporator 5 Connected with the concentrated magnesium nitrate tank 6, the concentrated magnesium nitrate tank 6 sends the material to the concentrated magnesium nitrate high tank 7 for further utilization through the concentrated magnesium nitrate pump, and the gas at the top of the magnesium nitrate evaporator 5 is cooled by the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com