High-throughput preparation method for metal parts

A metal parts, high-throughput technology, applied in the field of high-throughput preparation of metal parts, can solve the problems of increasing the research cycle and cost of materials, improve mechanical properties and yield, improve solidification structure, and reduce shrinkage cavities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

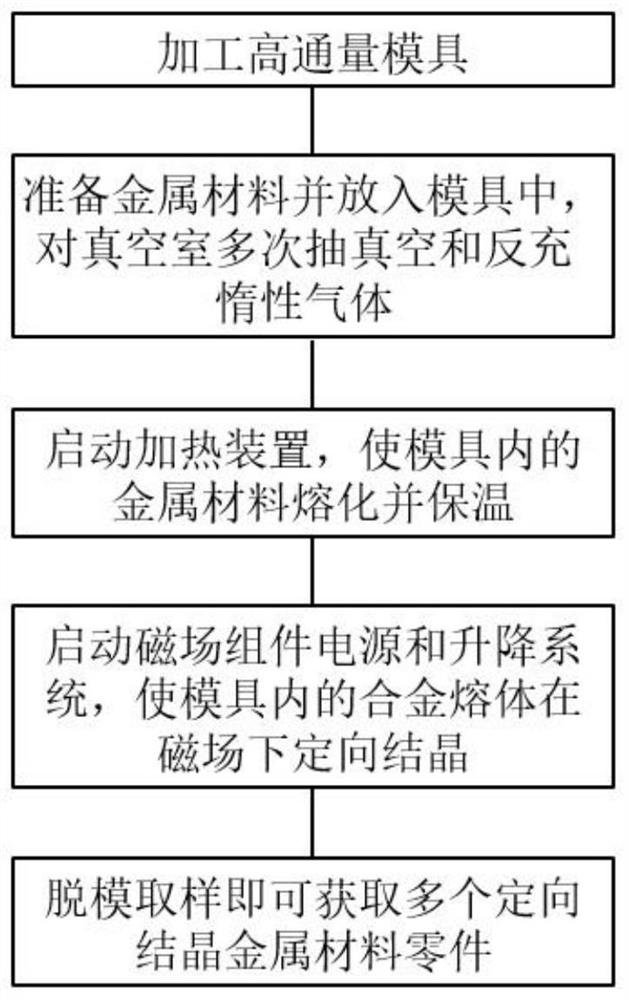

[0031] The invention provides a high-throughput preparation method of metal parts, comprising the following steps:

[0032] Placing raw metal into high-throughput molds;

[0033] In a protective atmosphere, the metal raw material in the high-throughput mold is heated and melted, and after the metal melt is obtained, the metal melt is subjected to directional crystallization;

[0034] The number of part sample slots in the high-throughput mold is ≥ 4, and the shape of the part sample slots is the same as that of the metal part.

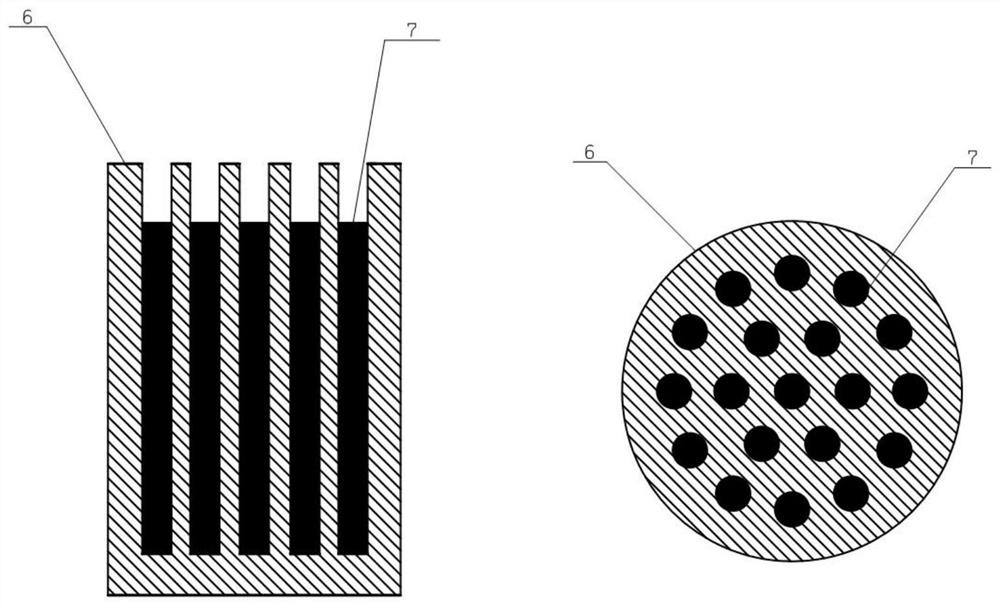

[0035] The present invention puts the metal raw material into the high-throughput mold; in the present invention, the number of part sample slots in the high-throughput mold is ≥4, preferably 4 to 19. In a specific embodiment of the present invention, The number of the part sample slots is preferably 4, 6, 16 or 19.

[0036] In the present invention, the shape of the part sample groove is the same as the shape of the metal part, and the shape of the ...

Embodiment 1

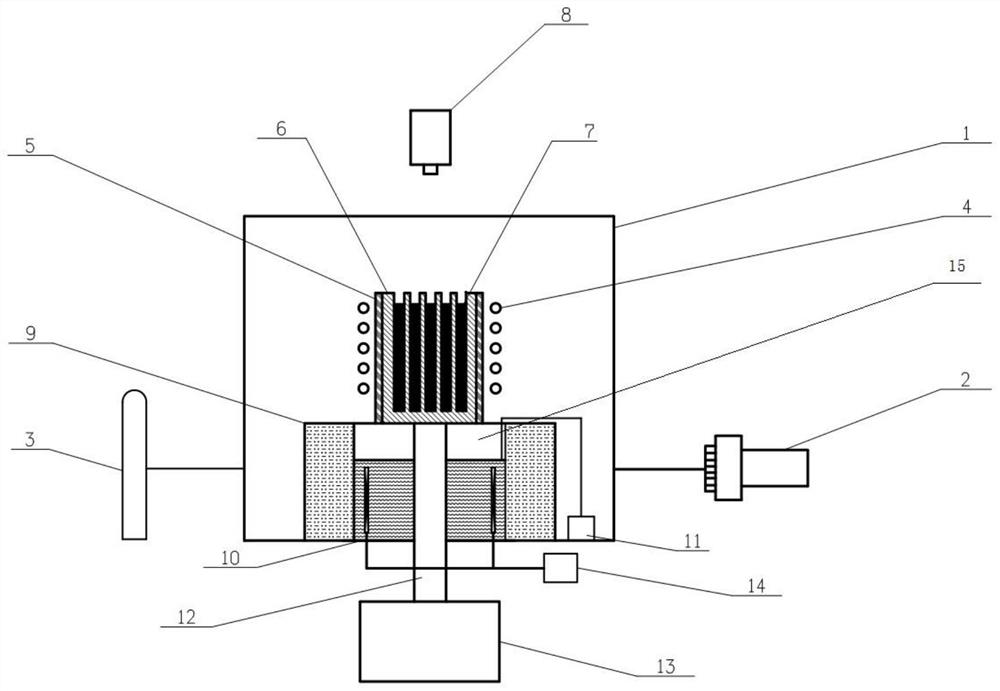

[0078] The high-throughput mold 6 (100mm in diameter and 150mm in height) for processing BN material is evenly distributed with 6 I-shaped sample grooves with a diameter of 20mm and a length of 100mm, such as Figure 4 shown.

[0079] Prepare 2kg of 304 stainless steel alloy particles with an average particle size of 1-2mm, fill them into the sample groove in the mold, and make the height of the alloy material 20mm lower than the top of the mold, such as Figure 4 shown. The high throughput mold 6 is placed in the inductor 5 of the vacuum chamber 1 .

[0080] Vacuum chamber 1 is evacuated to 1×10 by vacuum pump 2 -6 Pa, and then use the inert gas source 3 to backfill high-purity argon until the pressure of the vacuum chamber 1 is 5×10 4 Pa, repeat this process 5 times. Start the induction power supply, and keep warm for 30 minutes after the metal is completely melted.

[0081] Place the DC electromagnet in the crystallization chamber, start the magnetic field power supply...

Embodiment 2

[0085] A high-throughput mold (120mm in diameter and 200mm in height) for processing graphite materials, in which 19 cylindrical sample slots with a diameter of 10mm are evenly distributed, such as image 3 shown.

[0086] Prepare 5kg of Inconel625 alloy particles with an average particle size of 1-2mm, fill it into the sample groove in the mold, and make the height of the alloy material 20mm lower than the top of the mold, such as image 3 shown. Place the high-throughput mold into the inductor in the vacuum chamber.

[0087]Evacuate the vacuum chamber to 1×10 by vacuum pump -4 Pa, and then use an inert gas source to backfill high-purity argon until the pressure of the vacuum chamber is 8×10 4 Pa, repeat this process 3 times. Start the induction power supply, and keep warm for 10 minutes after the metal is completely melted.

[0088] Place the DC electromagnet in the crystallization chamber, start the magnetic field power supply to generate a DC magnetic field, such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com