Iodine working medium electric propulsion storage and supply system based on sonic nozzle flow control

A sonic nozzle and flow control technology, which is used in thrust reversers, space navigation equipment, space navigation aircraft, etc., can solve the problems of complex control rate, slow response, low long-term work reliability, etc., to improve system flow regulation. The effect of speed, simple structure, improving thermal efficiency and temperature control response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

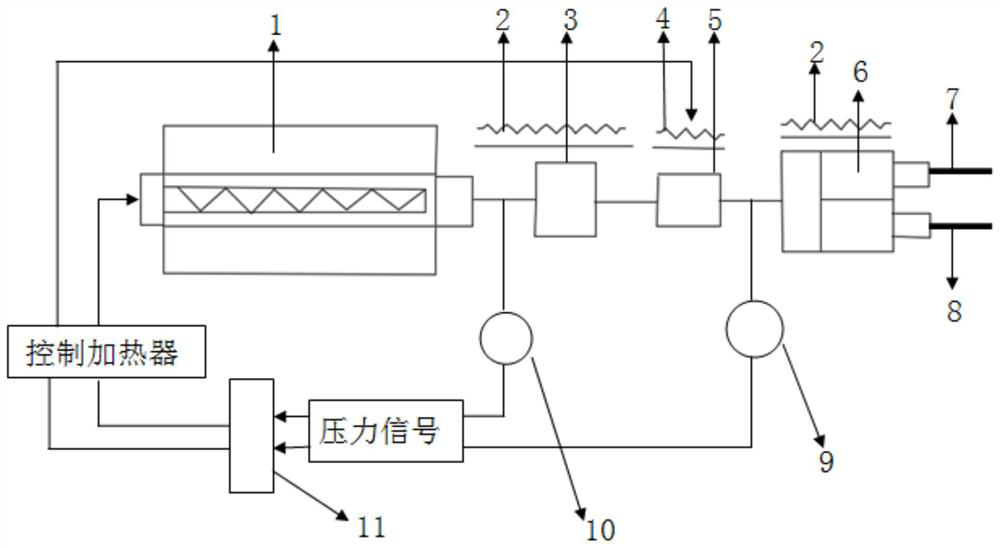

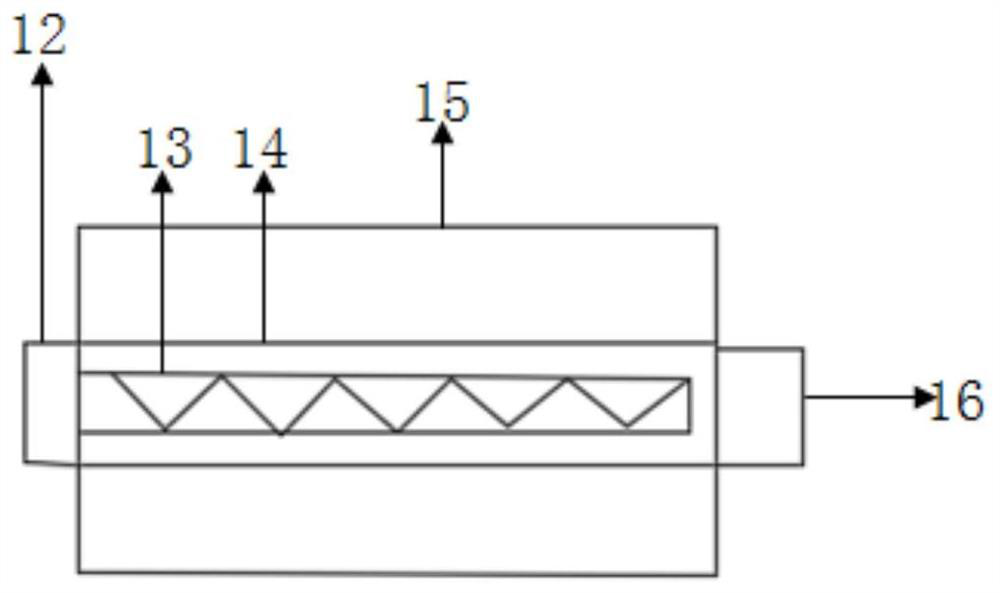

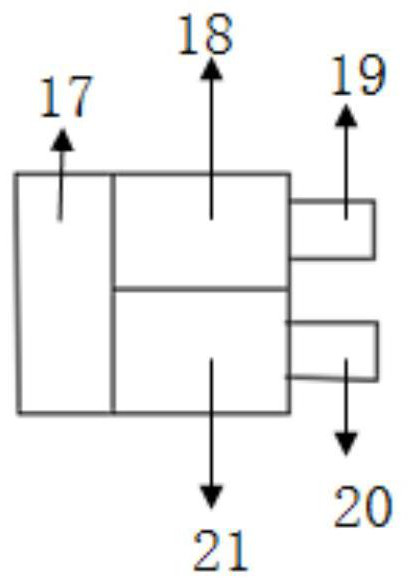

[0040] The iodine storage tank of the existing system is cylindrical, and the heating methods include external winding heating and internal end surface radiation heating. Typical supply system flow control methods include proportional control valve control and thermal throttle control. In terms of iodine working medium storage, cylindrical storage tanks are not conducive to the modular design of the system. External wrap tank heating methods are inefficient and slow to respond, which is not conducive to energy management and tank pressure regulation. The heating area of the internal end surface radiation heating is limited, and the response speed of the pressure control is slow. In terms of iodine working fluid supply, the proportional regulating valve is a frequently moving moving part, and contains non-metallic materials inside. Its long-term working reliability is low under high temperature environment and the possibility of condensation of iodine particles. The flow ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com