Heat shrink film packaging machine with micropore detection structure

A heat-shrinkable film, detection structure technology, applied in packaging, wrapping paper, transportation packaging, etc., can solve the risk of increasing the production process interruption, cannot pre-check the heat-shrinkable film, and the heat-shrinkable film packaging machine does not have a microporous detection mechanism and other problems to achieve the effect of reducing the risk of production interruption, reducing production costs and labor costs, and reducing inspection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

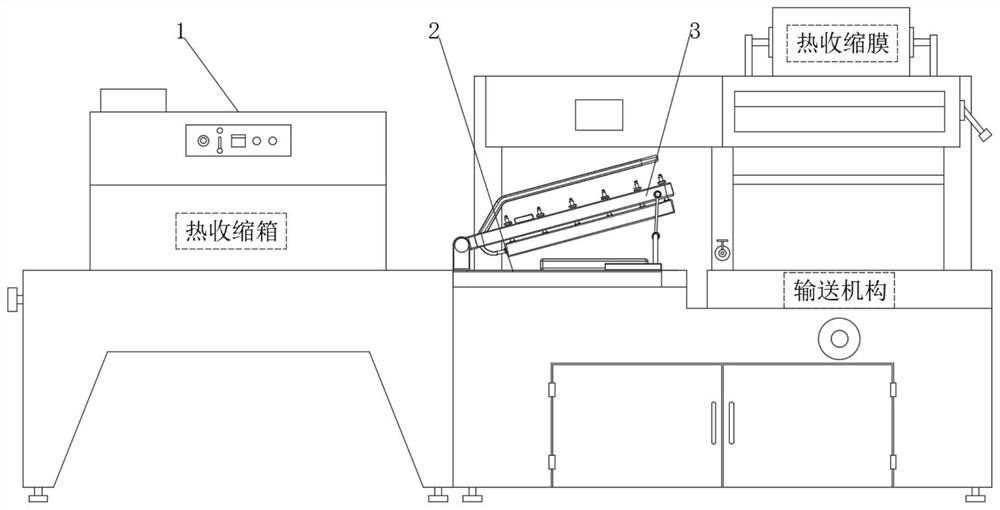

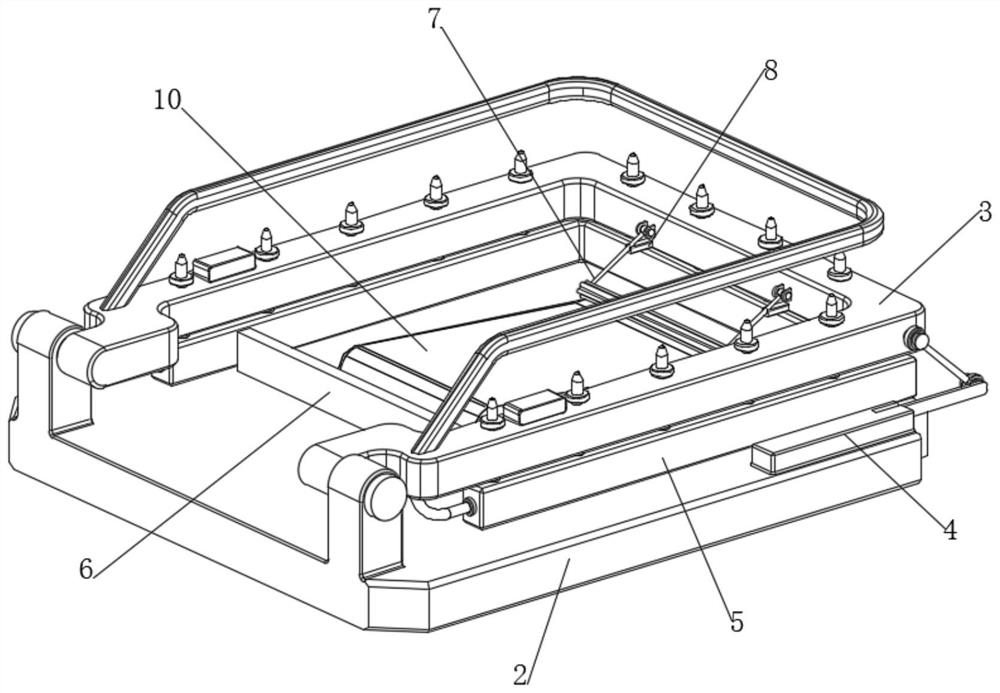

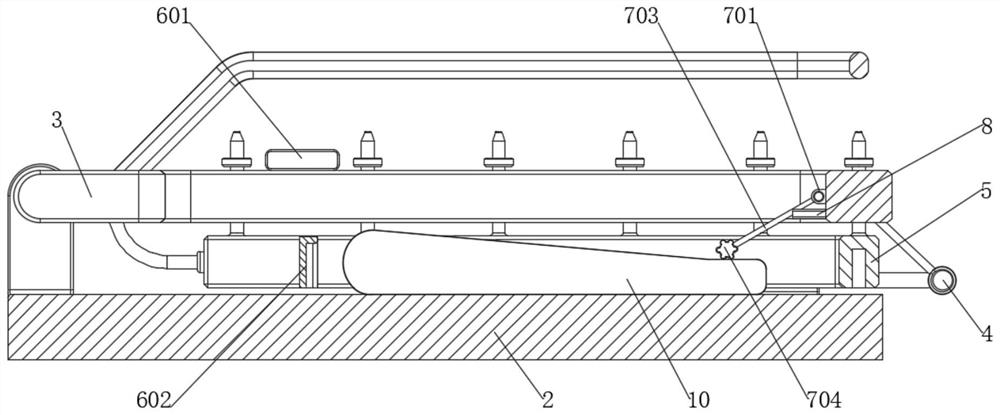

[0046] see Figure 1-10 , a heat shrinkable film packaging machine with a micropore detection structure, including a film cutting workbench 2 installed on the upper end of the packaging machine body 1, a heat shrinkable film package body 10 is placed on the upper end of the film cutting workbench 2, and the film cutting workbench 2 The upper end is rotatably connected with a fusion sealing film cutting frame 3, and the front and rear ends of the film cutting workbench 2 are equipped with a connecting rod driving mechanism 4 matching the melting sealing film cutting frame 3, and the connecting rod driving mechanism 4 is located on the melting sealing film cutting frame. 3. On the right side, the lower end of the fusion sealing film cutting frame 3 is fixedly connected with a fusion sealing device 5 matching the heat shrinkable film packaging body 10, and the inner end of the fusion sealing film cutting frame 3 is connected with a film extruding assembly 7, which is melted, seale...

Embodiment 2

[0055] see Figure 1-10 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 2 and embodiment 1 is: please refer to Figure 5 with Image 6 , the magnetic pressure rotating rod 703 is fixedly connected with a magnetic guide rod 7031, and the flexible shrinkage embossing roller 704 is wrapped with a pressure adjustment inner film 7041, and the pressure adjustment inner film 7041 is filled with a plurality of single-phase magnetic pole balls 7042, and the magnetic force The left end of the guide rod 7031 extends into the pressure regulating inner membrane 7041 and matches with the single-phase magnetic pole ball 7042 . After the single-phase magnetic pole ball 7042 is moved by the same magnetic pole, it will drive the pressure adjustment inner membrane 7041 to deform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com