Sprayable modified polypropylene material as well as preparation method and application thereof

A polypropylene material and polypropylene technology, applied in the field of sprayable modified polypropylene material and its preparation, can solve problems such as shedding, poor compatibility of polypropylene injection molded parts, etc., and achieve the effect of low industrial cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

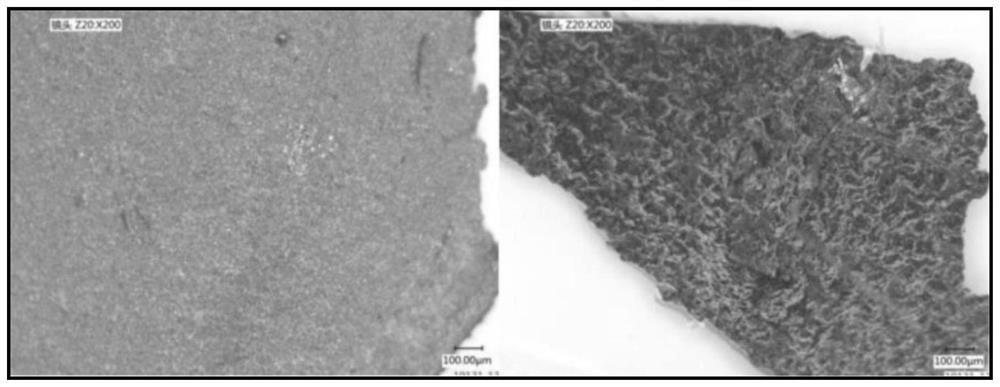

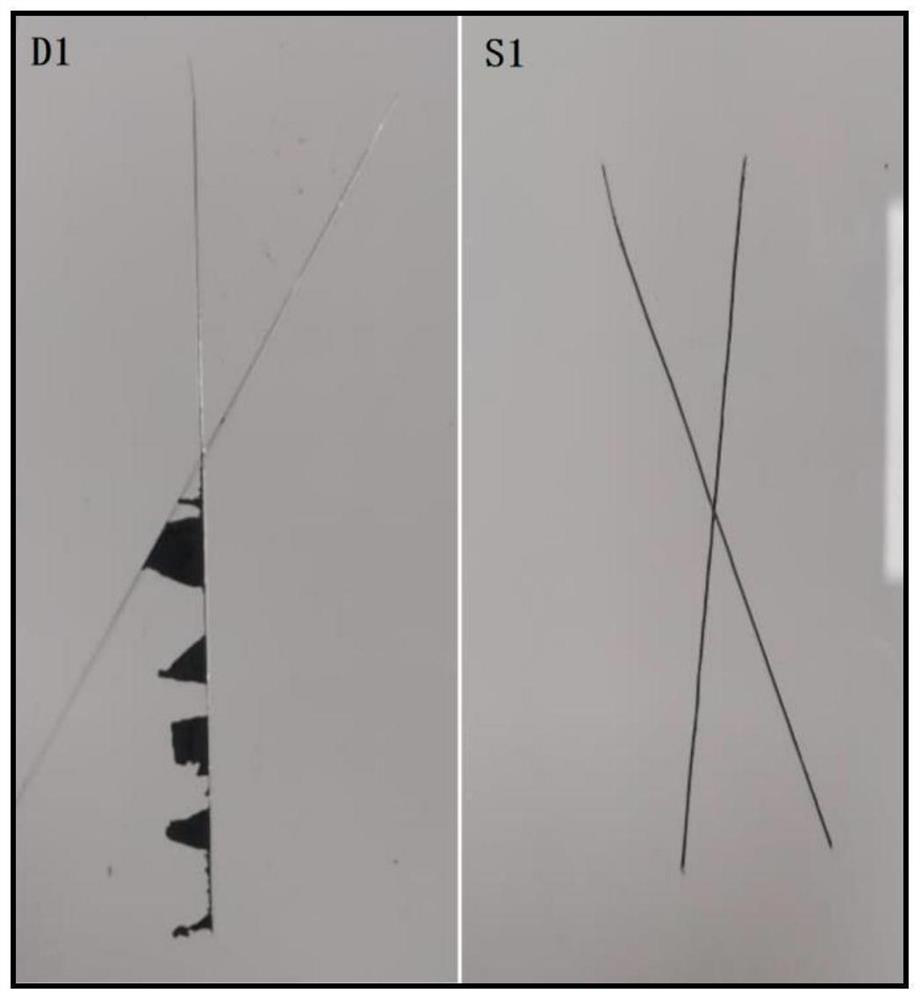

Image

Examples

Embodiment 1

[0054] Prepare the modified polypropylene material according to the following steps:

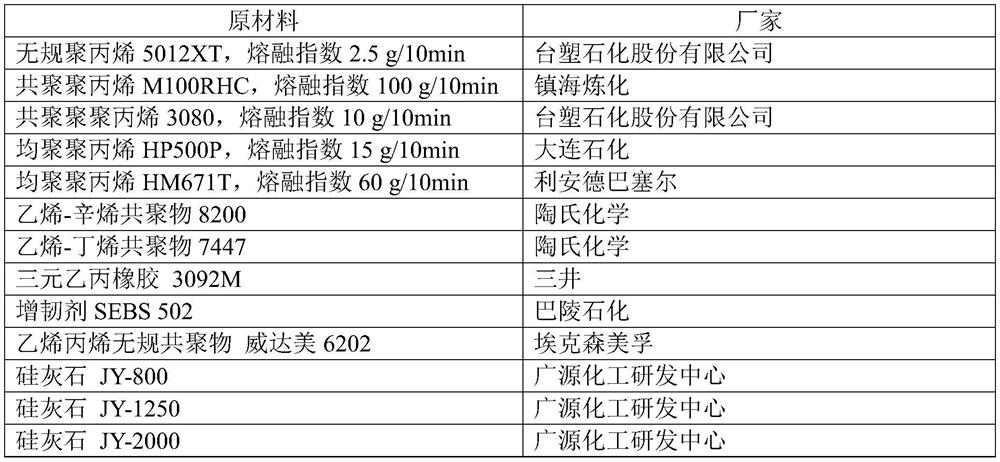

[0055] (1) Add 1000g of wollastonite JY-2000 and 30g of (3-mercaptopropyl)triethoxysilane into 10kg of absolute ethanol, heat and stir at 60°C for reaction, the stirring speed is 100rpm, and the stirring time is 1.5h. End the reaction. The reaction solution was centrifuged at 15000 rpm for 7 minutes, the solid was washed with absolute ethanol and then centrifuged, and the solid was obtained by repeating twice, and dried in a drying oven at -0.07MPaG for 3 hours at a vacuum degree of -0.07MPaG to obtain a modified silane coupling agent. Sexual wollastonite.

[0056] (2) Get 1000g silane coupling agent modified wollastonite, 30g (1R, 2S)-1-amino-2-vinylcyclopropanecarboxylic acid, 15g benzoin dimethyl ether and join in the dehydrated alcohol of 10kg, then Place it in an environment irradiated by an ultraviolet lamp and heat it for reaction. The reaction conditions are: 30° C., stirring speed...

Embodiment 2

[0066] Prepare the modified polypropylene material according to the following steps:

[0067] (1) Add 1000g of wollastonite JY-1250 and 30g of (3-mercaptopropyl)triethoxysilane into 12kg of absolute ethanol, heat and stir at 65°C for reaction, the stirring speed is 150rpm, the stirring time is 2h, and the end reaction. Centrifuge the reaction solution at 20,000 rpm for 5 minutes, take the solid and wash it with absolute ethanol, then centrifuge, repeat twice to obtain the solid, and dry it in a drying oven at -0.08MPaG for 2 hours at a vacuum degree of -0.08MPaG to obtain a modified silane coupling agent. Sexual wollastonite.

[0068] (2) Take 1000g of silane coupling agent modified wollastonite, 40g of 1-amino-2-vinylcyclopropanecarboxylic acid, 20g of benzoin dimethyl ether and add them to 12kg of dehydrated ethanol, then place them in an ultraviolet lamp irradiation environment Heating reaction under low temperature, the reaction conditions are: 40°C, stirring speed 80rpm...

Embodiment 3

[0078] Prepare the modified polypropylene material according to the following steps:

[0079] (1) Add 1000g of wollastonite JY-6000 and 50g of (3-mercaptopropyl)triethoxysilane into 15kg of absolute ethanol, heat and stir at 70°C for reaction, the stirring speed is 200rpm, the stirring time is 3h, and the end reaction. Centrifuge the reaction solution at 30,000 rpm for 2 minutes, take the solid and wash it with absolute ethanol, then centrifuge, repeat twice to obtain the solid, dry it in a vacuum degree of -0.1MPaG, and dry it in a 70°C drying oven for 1 hour to obtain a modified silane coupling agent. Sexual wollastonite.

[0080] (2) Get 1000g silane coupling agent modified wollastonite, 50g (1R, 2S)-1-amino-2-vinyl cyclopropane carboxylic acid, 30g benzoin dimethyl ether and join in the dehydrated alcohol of 15kg, then Place it in an environment irradiated by an ultraviolet lamp and heat it for reaction. The reaction conditions are: 40° C., the stirring speed is 100 rpm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com