Radiative Cooling Self-Cleaning Coatings

A radiation cooling and self-cleaning technology, applied in the direction of reflective/signal coatings, conductive coatings, coatings, etc., can solve the problems of unsatisfactory long-term effect, decline of radiation cooling effect, dust pollution on the coating surface, etc., to achieve good self-cleaning Cleaning effect, long-term stable cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

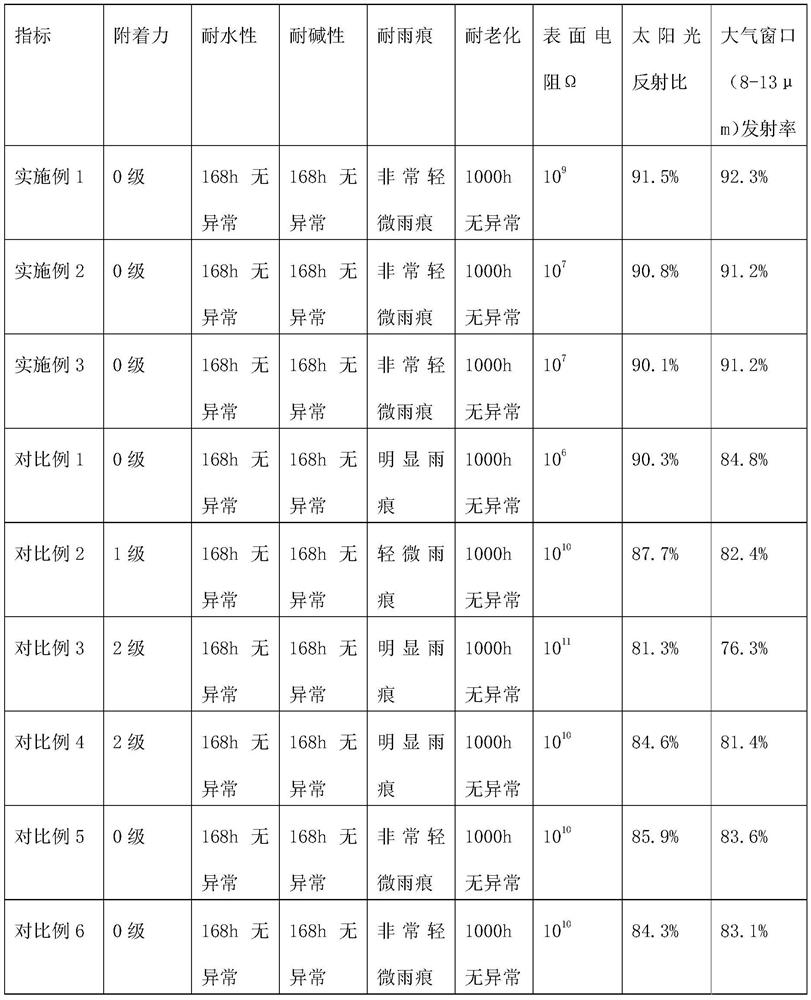

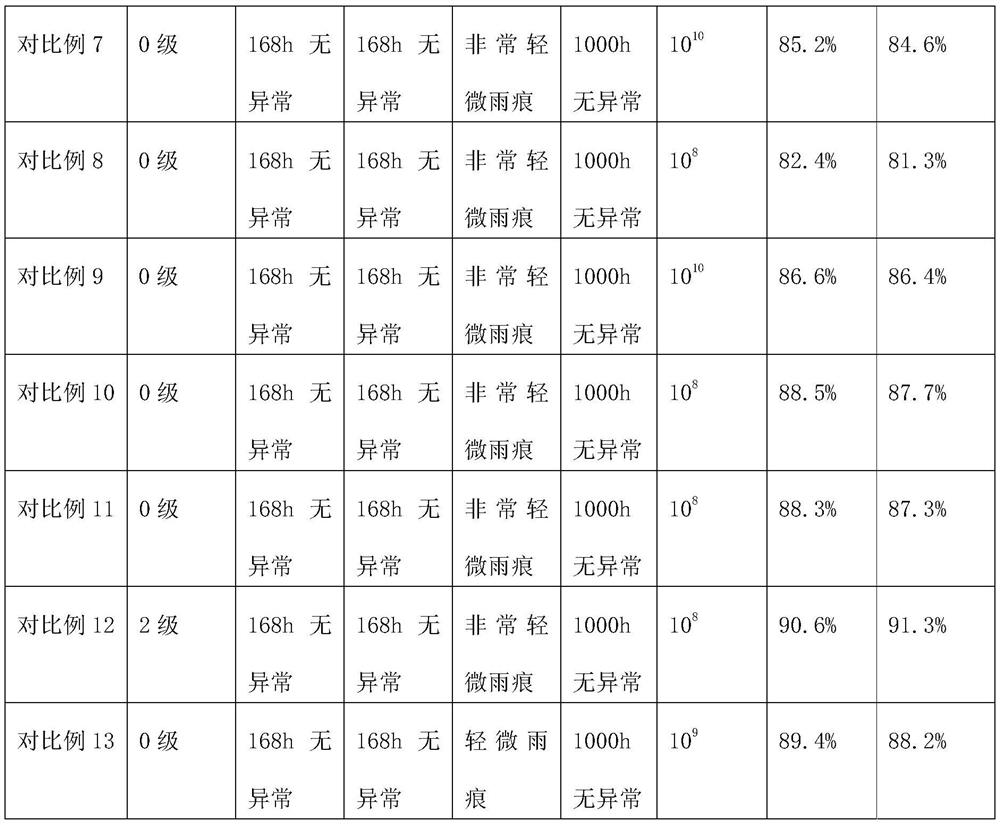

Examples

Embodiment 1

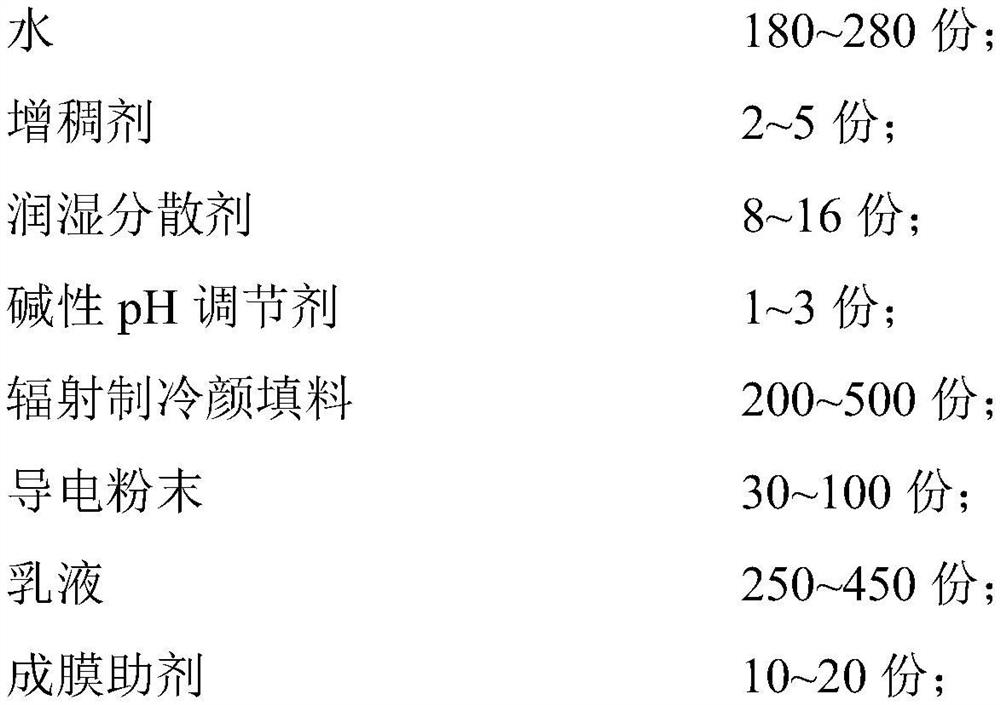

[0073] This example provides a high-performance radiant cooling self-cleaning coating, including a primer layer and an upper layer coating, and the raw materials are prepared according to the following ratios:

[0074] (1) Primer coating: water 180Kg, thickener 2Kg, defoamer 6Kg, wetting and dispersing agent 16Kg, PH regulator 1Kg, radiation refrigeration filler 500Kg, conductive powder 30Kg, emulsion 250Kg, film-forming aid 15Kg.

[0075] The thickener is associative polyurethane thickener: associative alkali swelling thickener: hydroxyethyl cellulose ether in a ratio of 2:1:2.

[0076] The radiation refrigeration filler is high infrared reflectivity titanium dioxide: nano-alumina is 1:1.

[0077] The conductive powder is conductive titanium dioxide.

[0078] The emulsion is silicone-acrylic emulsion.

[0079] Among them, the film-forming aid alcohol ester twelve: propylene glycol butyl ether: dipropylene glycol dimethyl ether is 8:4:3.

[0080] (2) Upper coating: water 25...

Embodiment 2

[0085] This example provides a high-performance radiant cooling self-cleaning coating, including a primer layer and an upper layer coating, and the raw materials are prepared according to the following ratios:

[0086] (1) Primer coating: water 220Kg, thickener 3Kg, defoamer 4Kg, wetting and dispersing agent 12Kg, PH regulator 2Kg, radiation refrigeration filler 280Kg, conductive powder 49Kg, emulsion 320Kg, film-forming aid 10Kg, curing agent 100Kg.

[0087] Wherein the thickener is preferably associative polyurethane thickener: water-based bentonite is 3:2.

[0088] Among them, the radiative refrigeration filler nano-alumina: nano-zinc oxide: ceramic powder is 4:4:1.

[0089] Among them, the conductive powder conductive titanium dioxide: tin oxide powder is 6:1.

[0090] The emulsion is preferably a hydroxy acrylic emulsion (hydroxyl value≤100): the curing agent is 3.2:1.

[0091] Coalescent agent alcohol ester twelve: propylene glycol diacetate: dipropylene glycol dimeth...

Embodiment 3

[0097] This example provides a high-performance radiant cooling self-cleaning coating, including a primer layer and an upper layer coating, and the raw materials are prepared according to the following ratios:

[0098] (1) Primer coating: water 280Kg, thickener 5Kg, defoamer 3Kg, wetting and dispersing agent 8Kg, PH regulator 3Kg, radiation refrigeration filler 200Kg, conductive powder 90Kg, emulsion 400Kg, film-forming aid 11Kg.

[0099] Wherein the thickener is preferably associative polyurethane thickener: water-based bentonite: associative alkali swelling thickener in a ratio of 3:2:1.

[0100] Among them, the radiation refrigeration filler high infrared reflection titanium dioxide: ceramic powder is 8:1.

[0101] Among them, the conductive powder conductive titanium dioxide: conductive mica powder: tin oxide powder is 1:2:1.

[0102] The emulsion is an acrylic emulsion.

[0103] Coalescent agent alcohol ester twelve: propylene glycol butyl ether is 4:1.

[0104] (2) Up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com