Poultry egg protein gel particle and production method and application thereof

A technology of protein gel and production method, applied in application, dairy products, food science, etc., can solve problems such as darkening of color, swelling of water absorption, softening of gel, etc., so as to inhibit gel softening, improve bad properties, and nutrition rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

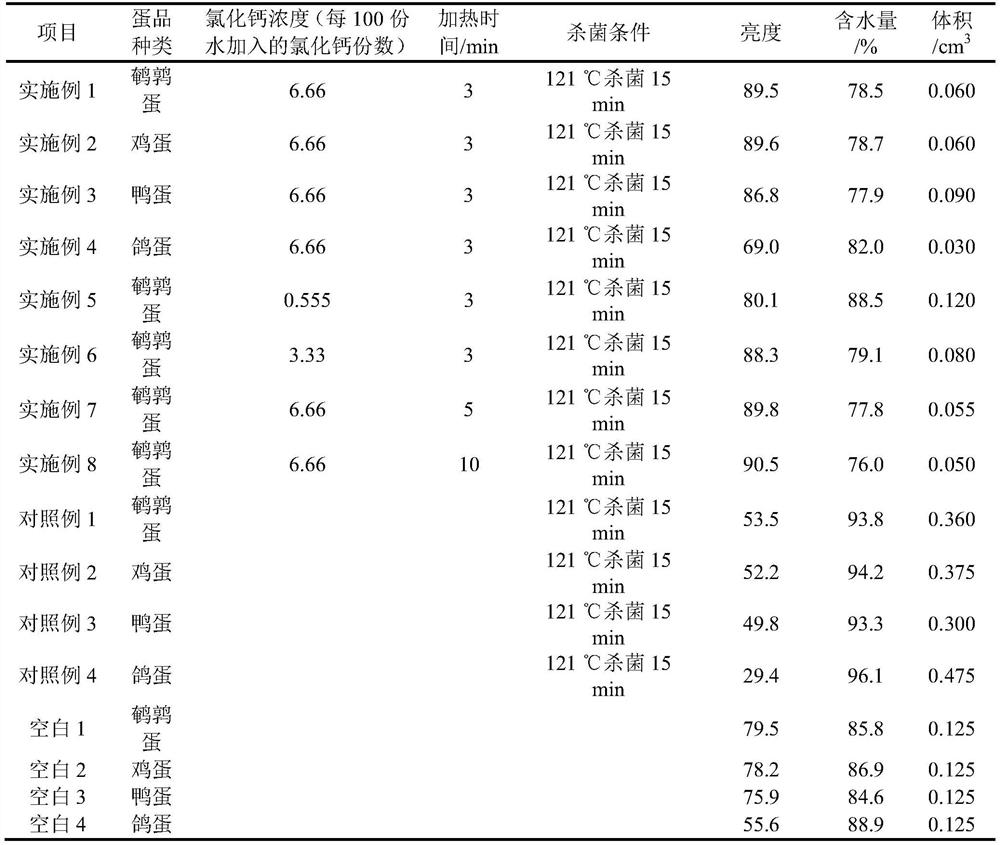

[0037] A production method of poultry egg protein gel particles, comprising the following steps:

[0038] (1) Put the egg white of quail eggs in a 90°C water bath for 30 minutes to incubate to obtain a protein gel, and cut it into small particles;

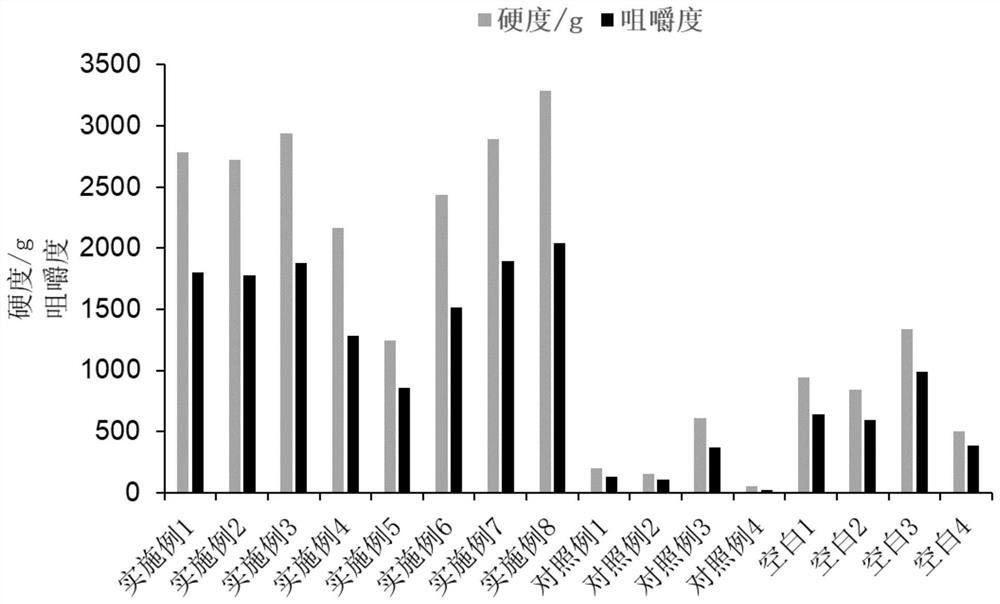

[0039]In step (1), the egg white is uniform egg white stirred by an electromagnetic stirrer at a stirring speed of 1500r / min for 10 minutes, and the obtained protein gel particles have a hardness of 940.4g, a chewiness of 642.6, a water content of 85.8%, a brightness of is 79.5 and the volume is 0.125cm 3 .

[0040] (2) Dissolve 6.66 parts (parts by mass; the same below) of calcium chloride in 100 parts of water and heat to 100°C;

[0041] (3) Place the protein gel particles obtained in step (1) in the calcium chloride solution obtained in step (2) and keep heating for 3 minutes and then place them in ice water to cool for 5 minutes;

[0042] In step (3), the material ratio of the added protein gel particles to the calcium chlor...

Embodiment 2

[0047] A kind of production method of poultry egg protein gel particle, the difference between this embodiment and embodiment 1 is:

[0048] Chicken eggs adopt chicken eggs. The obtained egg protein gel particles had a hardness of 840.9g, a chewiness of 596.1, a water content of 86.9%, a brightness of 78.2, and a volume of 0.125cm 3 .

[0049] Egg protein gel particles heated by calcium chloride solution with a specific gravity of 6.66:100 were sterilized at 121°C for 15 minutes, the gel hardness became 2721.6g, the chewiness became 1776.4, and the water content became 78.7 %, the brightness becomes 89.6, and the volume becomes 0.06cm 3 .

[0050] For the production of a high-protein milk drink, the protein gel particles obtained in this embodiment are added to milk in a proportion of 32% of the total weight of the drink, and pasteurized to make a milk drink with granular solids. The hardness of the protein gel particles in the obtained milk drink is 1485.1g, the chewiness...

Embodiment 3

[0052] A kind of production method of poultry egg protein gel particle, the difference between this embodiment and embodiment 1 is:

[0053] Poultry eggs adopt duck eggs. The hardness of the obtained duck egg protein gel particles is 1338.7g, the chewiness is 987.8, the water content is 84.6%, the brightness is 75.9, and the volume is 0.125cm 3 .

[0054] However, after the egg protein gel particles heated by calcium chloride solution were sterilized at 121°C for 15 minutes, the gel hardness became 2936.3g, the chewiness became 1880.5, the water content became 77.9%, and the brightness became 86.8. The volume becomes 0.09cm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com