Magnetic Fenton catalyst as well as preparation method and application thereof

A catalyst, Fenton's technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor ability to reduce ferric iron, generation of iron sludge and inconvenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: the preparation method of the magnetic Fenton catalyst of the present embodiment, carry out according to the following steps:

[0033] 1. Dissolve 10g of tourmaline and 8g of NaOH in 200mL of ultrapure water, and the flow rate is 600mL min -1 Nitrogen, and the ventilation time is 30min to obtain the mixed solution Ⅰ;

[0034] 2. Add a few drops of concentrated sulfuric acid to 100mL of ultrapure water to make the pH 1, then add 0.25mol of ferrous sulfate and 0.25mol of ferric sulfate in sequence to obtain the acidic mixture II;

[0035] 3. When the nitrogen flow rate is 600mL min -1 Under the condition of -1 Add it dropwise to the mixed solution I at a speed of 300 rpm, and then centrifuge at a speed of 7000 rpm for 3 min to obtain a solid phase;

[0036] 4. Dry the solid phase at 60°C under vacuum for 24 hours, and then grind for 30 minutes to obtain a magnetic Fenton catalyst, which is a surface-loaded Fe 3 o 4 Tourmaline.

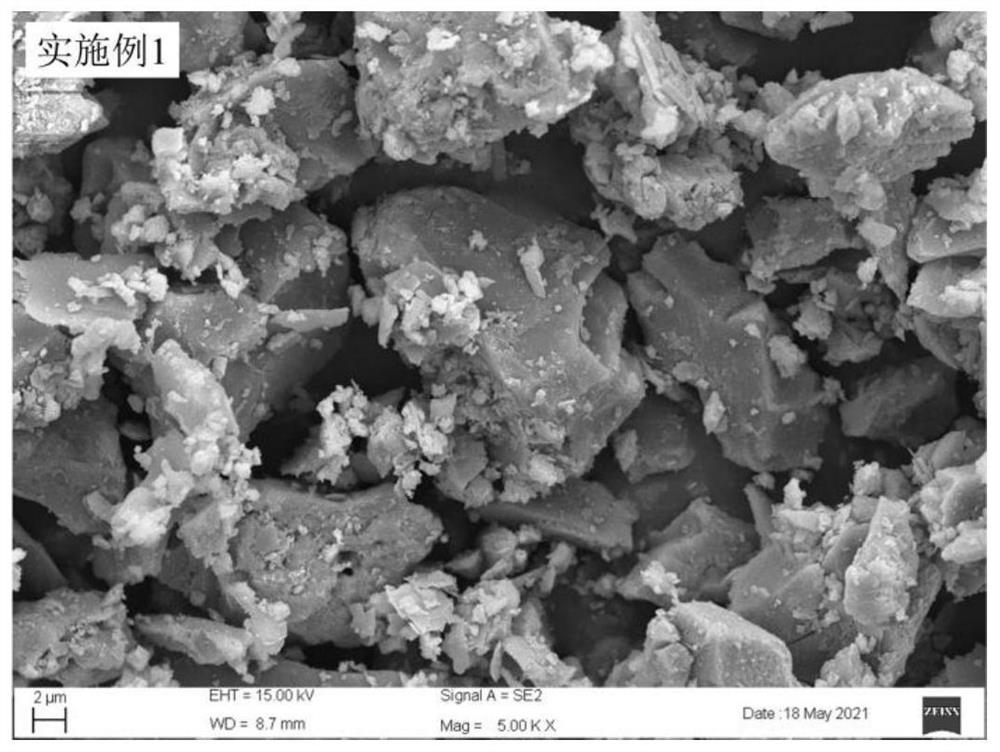

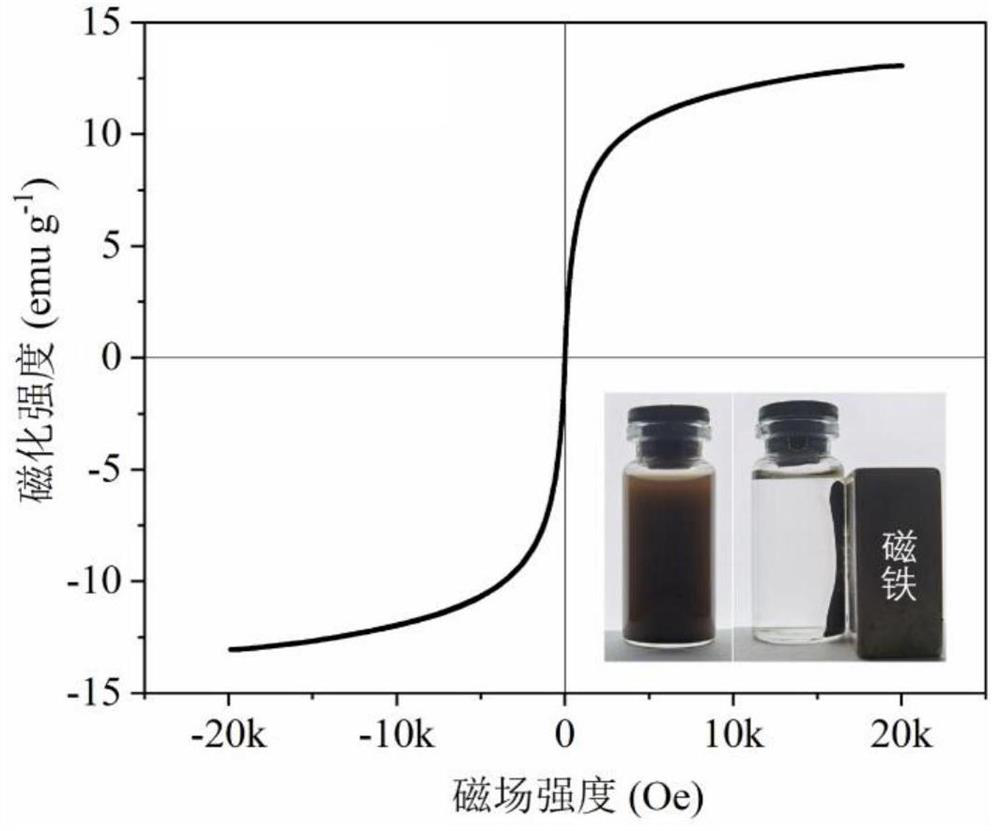

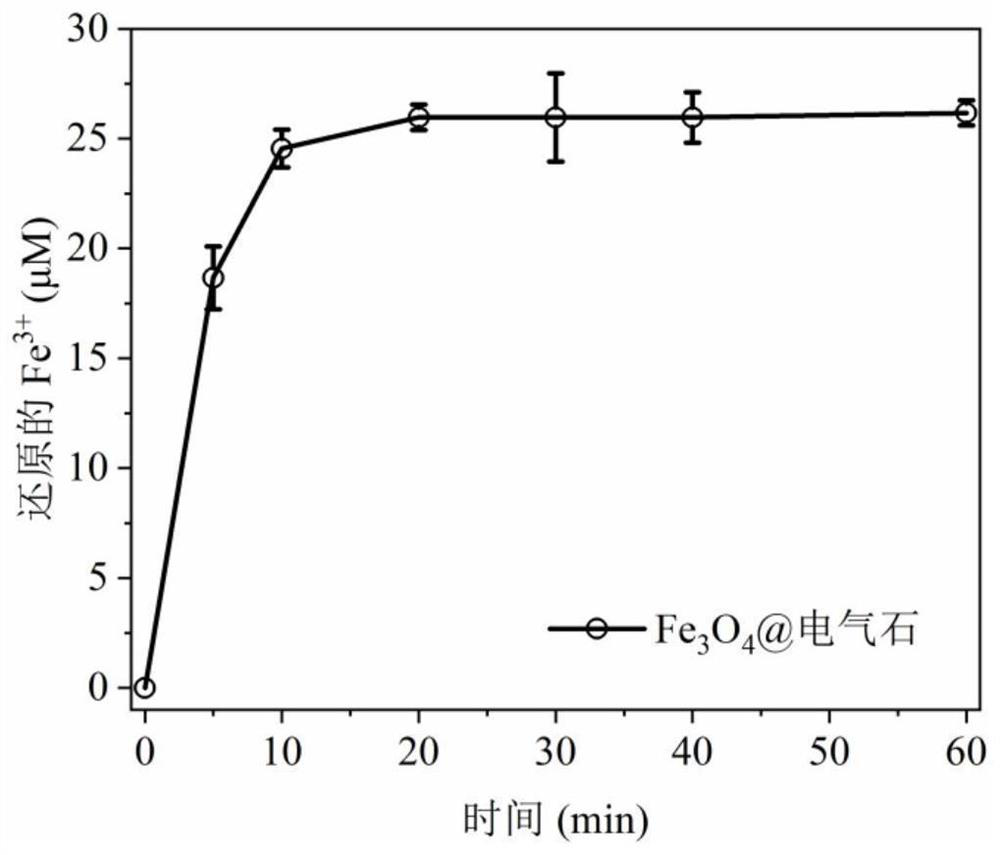

[0037] The scanning ele...

Embodiment 2

[0041] Embodiment 2: the preparation method of the magnetic Fenton catalyst of the present embodiment, carry out according to the following steps:

[0042] 1. Dissolve 5g of tourmaline and 6g of NaOH in 200mL of ultrapure water, and the flow rate is 400mL min -1 Nitrogen, and the ventilation time is 30min to obtain the mixed solution Ⅰ;

[0043] 2. Add a few drops of concentrated sulfuric acid to 100mL of ultrapure water to make the pH 1.5, then add 0.15mol of ferrous sulfate and 0.15mol of ferric sulfate in sequence to obtain the acidic mixture II;

[0044] 3. When the nitrogen flow rate is 400mL min -1 Under the condition of -1 Add it dropwise to the mixed solution I at a speed of 500 rpm, and then continue to stir at 300 rpm for 25 minutes after the dropwise addition, and then centrifuge at 5000 rpm for 5 minutes to obtain a solid phase;

[0045] 4. Dry the solid phase at 80°C under vacuum for 12 hours, and then grind for 30 minutes to obtain a magnetic Fenton catalyst, ...

Embodiment 3

[0049] Embodiment 3: the preparation method of the magnetic Fenton catalyst of the present embodiment, carry out according to the following steps:

[0050] 1. Dissolve 15g of tourmaline and 10g of NaOH in 200mL of ultrapure water, and the flow rate is 1000mL min -1 Nitrogen, and the ventilation time is 30min to obtain the mixed solution Ⅰ;

[0051] 2. Add a few drops of concentrated sulfuric acid to 100mL of ultrapure water to make the pH 2, then add 0.45mol of ferrous sulfate and 0.45mol of ferric sulfate in sequence to obtain the acidic mixture II;

[0052] 3. When the nitrogen flow rate is 1000mL min -1 Under the condition of -1 Add it dropwise to the mixed solution I at a speed of 400 rpm, and then centrifuge at 6000 rpm for 4 min to obtain a solid phase;

[0053] 4. Dry the solid phase at 70°C under vacuum for 24 hours, and then grind for 30 minutes to obtain a magnetic Fenton catalyst, which is a surface-loaded Fe 3 o 4 Tourmaline.

[0054] The scanning electron mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com