Preparation method and application of manganese-rich Mn-SAPO-18 molecular sieve catalyst

A mn-sapo-18, molecular sieve technology, applied in molecular sieve catalysts, catalyst activation/preparation, separation methods, etc., can solve the problems of narrow catalyst activity temperature range, low preparation yield, etc., and achieve high solid raw powder yield, Wide temperature window and excellent SCR activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] After mixing 12.45g orthophosphoric acid with a certain amount of deionized water, slowly add 8.88g pseudoboehmite, add 12.02g silica sol after mixing evenly, add a certain mass fraction of manganese acetate solution after mixing evenly, fully After stirring, 15.51g of N,N-diisopropylethylamine was added dropwise;

[0045] Put the fully stirred gel into the hydrothermal reactor and crystallize at 180°C for 24 hours, then cool at room temperature, separate the solid crystallized product from the mother liquor, wash until neutral, and dry at 110°C for 12 hours. Then bake in air at 550°C for 6h, with a heating rate of 1°C / min;

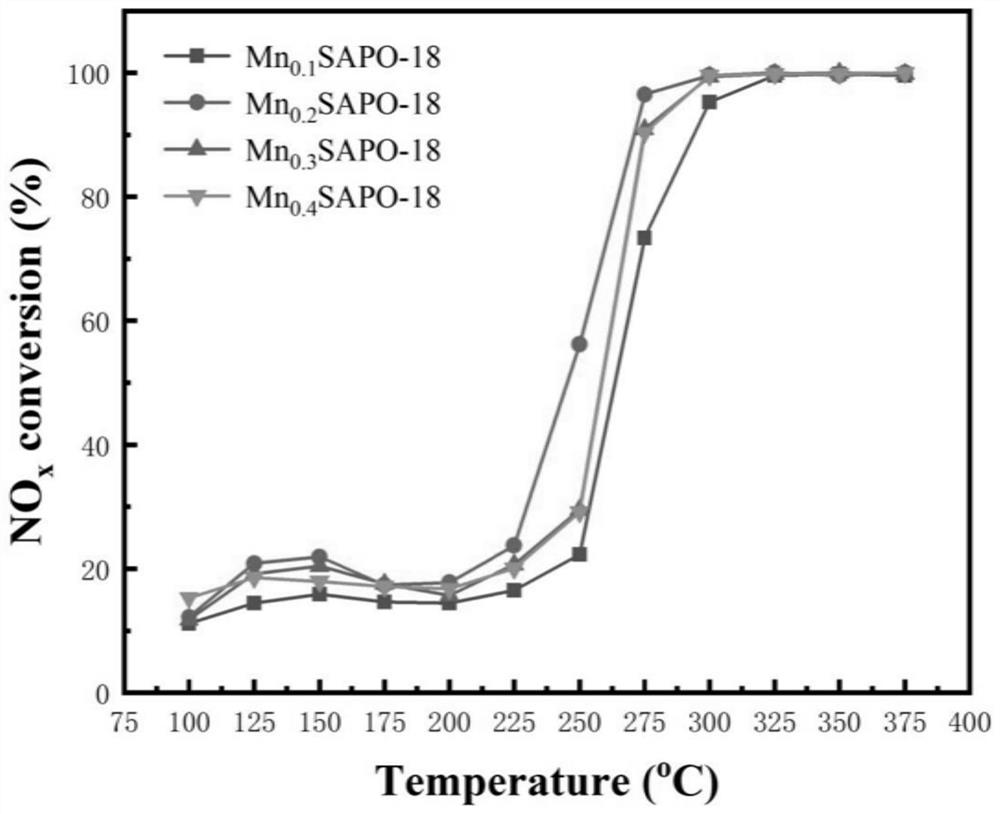

[0046] In this method, the amount of each reactant is controlled so that the reaction system has the following mass ratio relationship, that is, the control of Al 2 o 3 ,P 2 o 5 、H 2 O, SiO 2 , manganese acetate, N,N-diisopropylethylamine molar ratio is 1:0.9:68:1:(0.1-0.4):2.0, wherein manganese acetate and Al 2 o 3 The ratio is controlled...

Embodiment 2

[0052] After mixing 12.45g orthophosphoric acid with a certain amount of deionized water, slowly add 8.88g pseudoboehmite, add 12.02g silica sol after mixing evenly, add a certain mass fraction of manganese acetate solution after mixing evenly, fully Add 15.51g template agent dropwise after stirring;

[0053] Put the fully stirred gel into the hydrothermal reactor and crystallize at 180°C for 24 hours, then cool at room temperature, separate the solid crystalline product from the mother liquor, wash until neutral, and dry at 110°C for 12 hours. Then bake in air at 550°C for 6h, with a heating rate of 1°C / min;

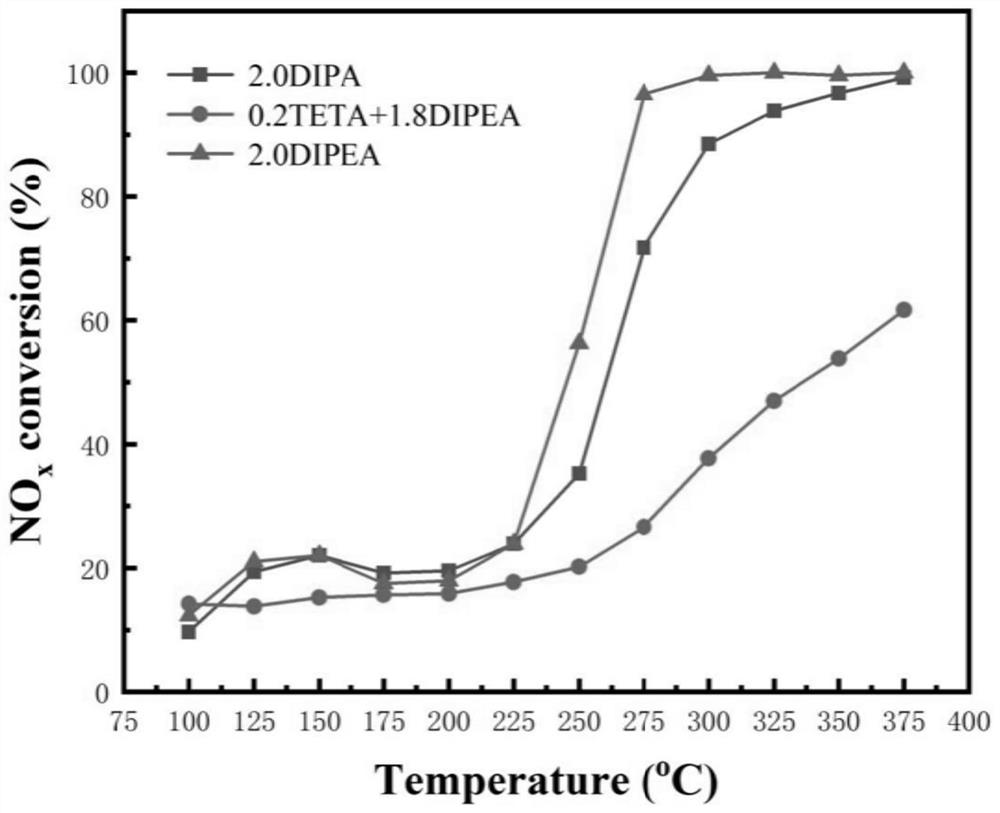

[0054] In this method, the amount of each reactant is controlled so that the reaction system has the following mass ratio relationship, that is, the control of Al 2 o 3 ,P 2 o 5 、H 2 O, SiO 2 The molar ratio of manganese acetate and template agent is 1:0.9:68:1:0.2:2.0, wherein the types of template agent are N,N-diisopropylethylamine (DIPEA), diisopropylamine (DI...

Embodiment 3

[0057] After mixing 12.45g orthophosphoric acid with a certain amount of deionized water, slowly add 8.88g pseudoboehmite, add 12.02g silica sol after mixing evenly, add a certain mass fraction of manganese acetate solution after mixing evenly, fully After stirring, 15.51g of N,N-diisopropylethylamine was added dropwise;

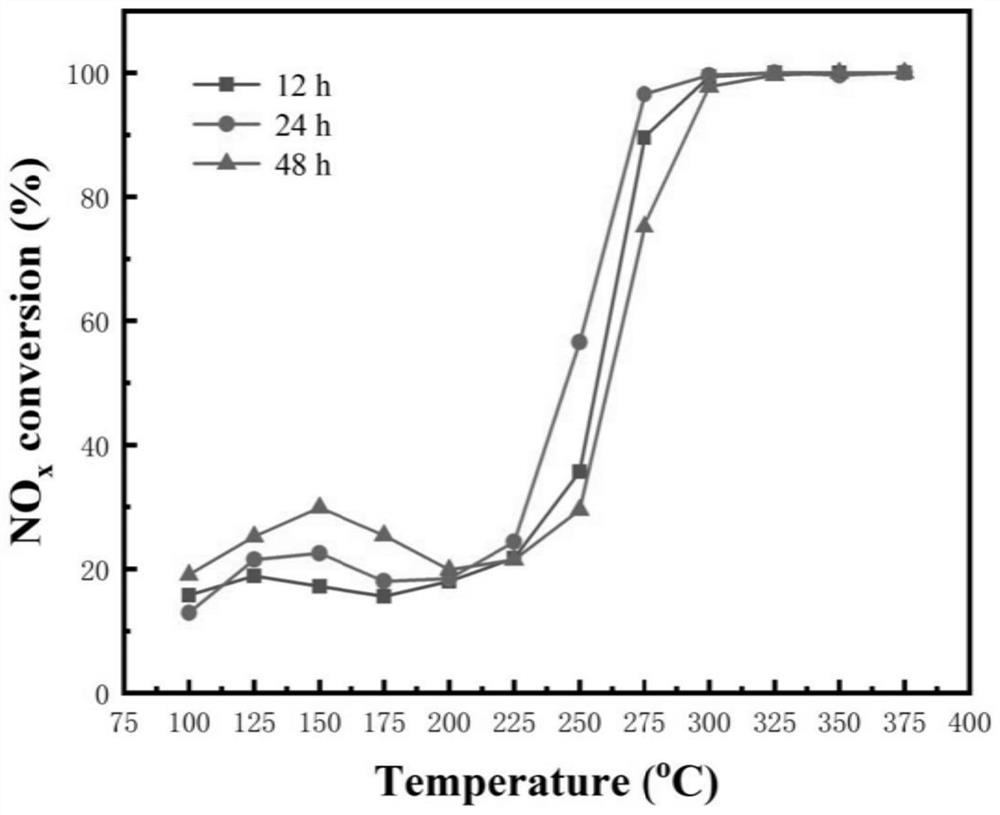

[0058] Put the fully stirred gel into the hydrothermal reactor and crystallize at 180°C for 12-72 hours, then cool at room temperature, separate the solid crystallized product from the mother liquor, wash until neutral, and dry at 110°C 12h, and then roasted in air at 550°C for 6h, with a heating rate of 1°C / min;

[0059] In this method, the hydrothermal crystallization time is controlled, that is, the crystallization time is 12 to 72 hours, among which 12 hours, 24 hours, and 48 hours are used.

[0060] image 3 Shown is to screen the hydrothermal crystallization time required for the preparation of molecular sieve catalysts, by image 3 It can be seen t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com