Fireproof treatment process for steel structure

A technology for fire prevention and steel structure, applied in fire prevention, surface pretreatment, building components, etc., can solve problems affecting steel structure performance, fire failure, paint and paint peeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

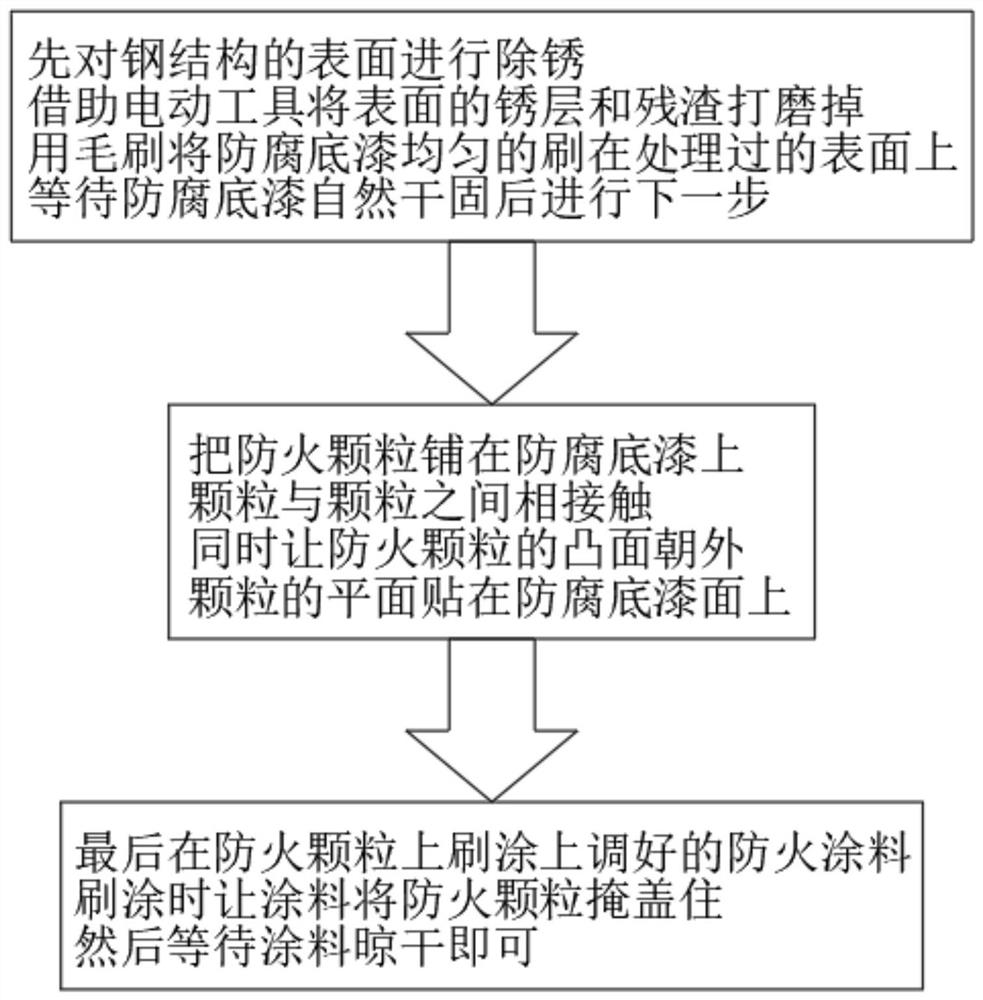

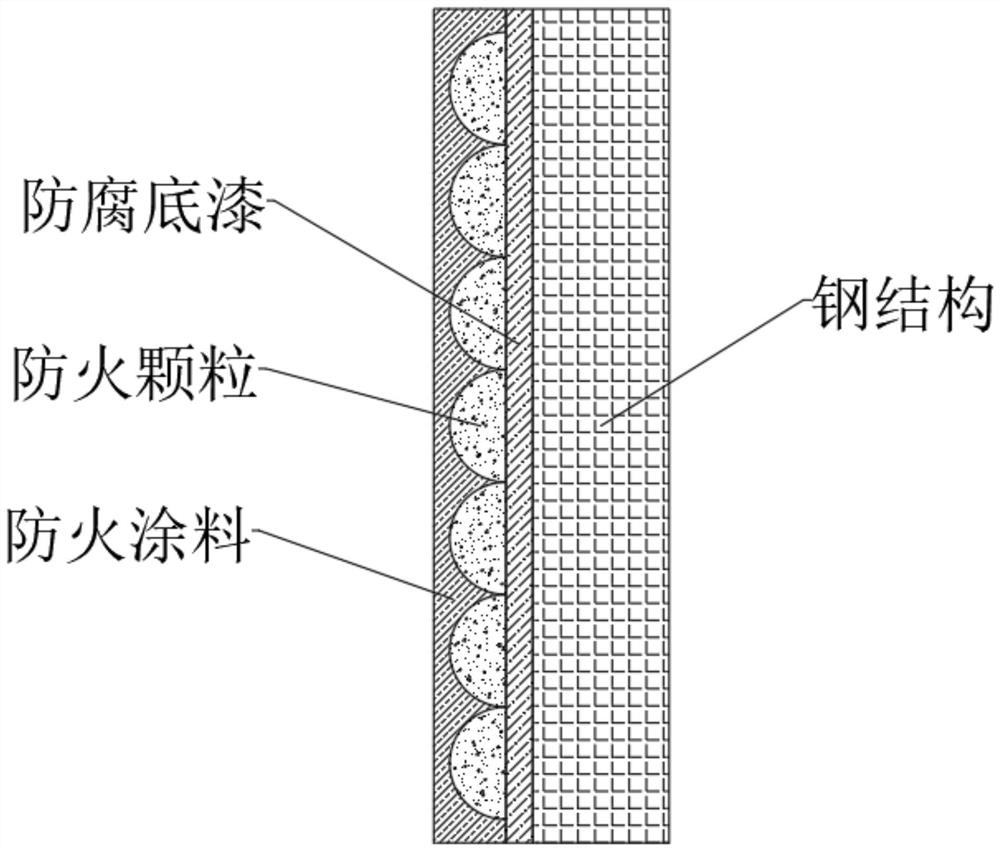

[0048] see Figure 1-6 , a fireproof treatment process for steel structures, please refer to Figure 1-2 , including the following steps:

[0049] S1, first derust the surface of the steel structure, use electric tools to polish off the rust layer and residue on the surface, use a brush to evenly brush the anti-corrosion primer on the treated surface, wait for the anti-corrosion primer to dry naturally proceed to the next step;

[0050] S2, spreading the fireproof particles on the anticorrosion primer, the particles are in contact with each other, and at the same time, let the convex surface of the fireproof particles face outward, and the plane of the particles is attached to the anticorrosion primer surface;

[0051] S3. Finally, brush the adjusted fireproof paint on the fireproof particles, let the paint cover the fireproof particles when brushing, and then wait for the paint to dry.

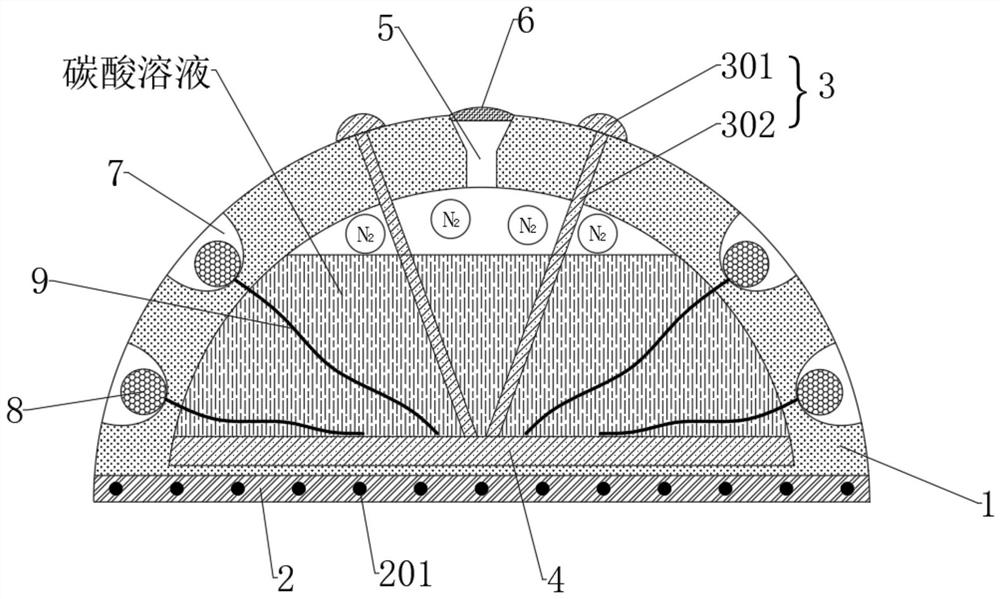

[0052] The laying method of fireproof particle in the described S2 step is:

[0053] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com