A cleaning device and cleaning method for ceramic tile processing capable of multi-angle edge grinding

A cleaning device and multi-angle technology, applied in the field of ceramic tile processing, can solve the problems of insufficient polishing and cleaning of the surface of ceramic tiles, inability to polish and polish the top of tiles, and insufficient thorough polishing of tiles, so as to ensure cleanliness, increase protection, increase Efficiency and Area Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

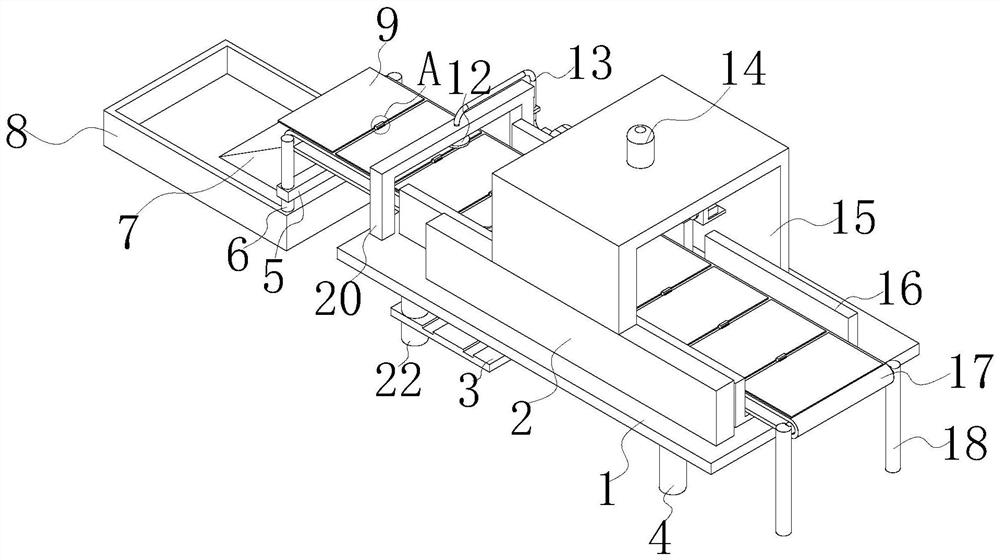

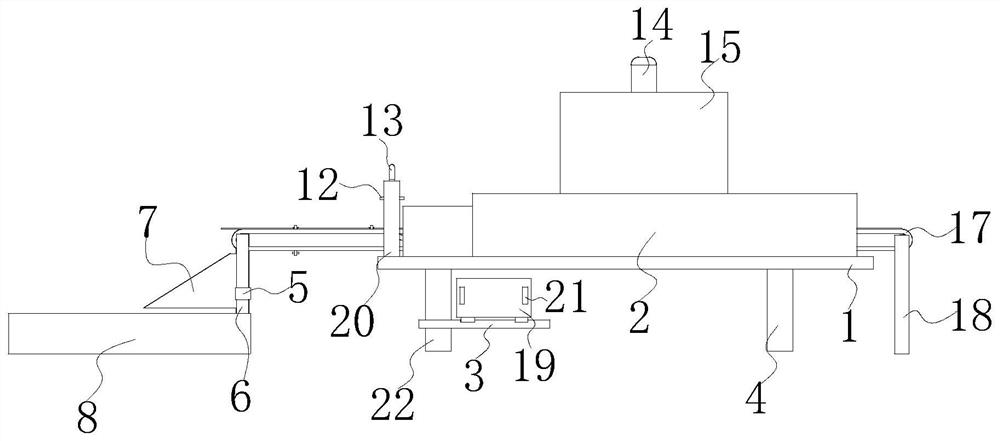

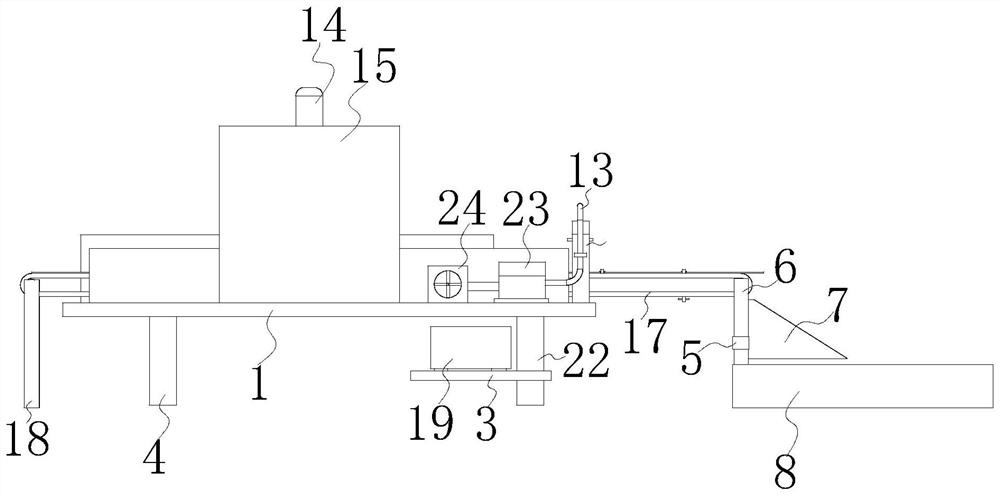

[0037] see Figure 1-7 , the present invention provides a technical solution: a cleaning device for ceramic tile processing capable of multi-angle edging, comprising a bottom plate 1 and a cleaning pool 8, and the cleaning pool 8 is located on one side of the bottom plate 1, and a vertical column is fixed on the top of the bottom plate 1. Plate 2, a support frame 15 is fixedly installed on the top of the vertical plate 2, a hydraulic telescopic rod 29 is fixedly installed in the inner cavity of the top of the support frame 15, a U-shaped frame 30 is fixedly installed at the bottom of the hydraulic telescopic rod 29, and the inside of the U-shaped frame 30 is fixedly installed. A grinding rod 37 is movably installed, a grinding disc 34 is fixedly installed on both sides of the grinding rod 37, a brush plate 36 is fixedly installed on the outer side of the U-shaped frame 30, a brush 35 is fixedly installed at the bottom of the brush plate 36, and the top of the bottom plate 1 is ...

Embodiment 2

[0040] like Figure 1-7 As shown, on the basis of the first embodiment, the present invention provides a technical solution: at least two first support legs 4 are fixedly installed at the bottom of the base plate 1, and at least two second support legs are fixedly installed at the bottom of the base plate 1 22. A support plate 3 is fixedly installed on the outer side of the second support leg 22, and a material trough 19 is movably installed on the top of the support plate 3.

[0041] In this embodiment, the polished tiles 9 continue to move with the conveyor belt 17 , and then the brush 35 slightly cleans the residues on the surface of the tiles 9 , so that the residues are flattened on the surface of the tiles 9 and then pass the inclined rods 28 to the tiles 9 . The residue on the surface is scraped off by the pulling force of the spring 27 to pull the oblique rod 28, and the oblique rod 28 drives the residue to pull out, and falls into the interior of the feeding trough 19...

Embodiment 3

[0043] like Figure 1-7 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a chute is provided inside the support plate 3, a slider is fixedly installed at the bottom of the material chute 19, and the interior of the chute is movably installed There are sliders, and at least two pull rings 21 are fixedly installed on the front surface of the material trough 19 .

[0044] In this embodiment, the function of the support plate 3 facilitates the support of the material chute 19 and facilitates the collection of sundries by the material chute 19 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com