Control process for preventing large wood shavings from being damaged through PB board

A shaving and breakage technology, which is applied in the direction of manufacturing tools, flat products, wood processing appliances, etc., can solve the problems of large shavings breakage, long shavings, etc., and achieve the effects of preventing glue cracking, strong viscosity, and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

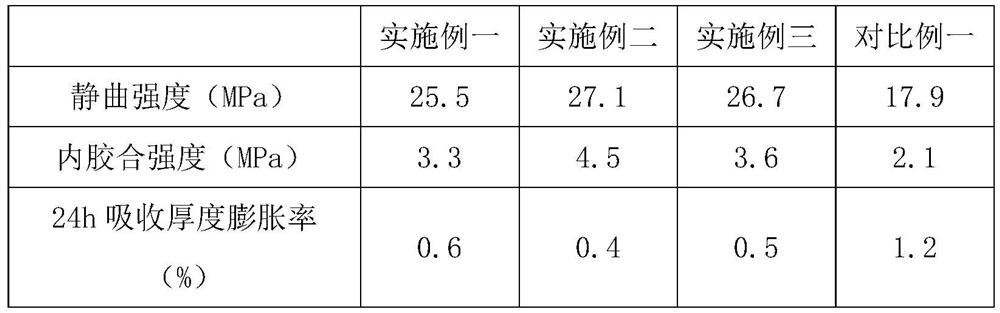

Examples

Embodiment 1

[0022] A kind of PB board that the present invention proposes prevents the control process of large shavings from being damaged, comprising the following steps:

[0023] S1. Prefer fir wood as the main raw material, cut it to obtain a cutting material with a size of 1cm, immerse the cutting material in the treatment solution for soaking treatment, control the temperature of the soaking solution at 38 ° C, control the soaking time at 1 hour, and then dry it for treatment Material, the treatment solution is obtained by compounding ammonium sulfite, trisodium citrate, polyether amine and 30% ethanol aqueous solution with a mass ratio of 2:5:1:12;

[0024] S2. Send the processed material dried in step S1 into a shaving machine to make shavings of the required size, use high-temperature flue gas drying technology, control the drying temperature to 420°C, and dry the shavings until the moisture content is 3%;

[0025] S3. According to the mass ratio of 7:1, the wood shavings obtain...

Embodiment 2

[0028] A kind of PB board that the present invention proposes prevents the control process of large shavings from being damaged, comprising the following steps:

[0029] S1. Prefer fir wood as the main raw material, cut it to obtain a cutting material with a size of 50cm, immerse the cutting material in the treatment solution for soaking treatment, control the temperature of the soaking solution at 48 °C, control the soaking time at 2 hours, and then dry it for treatment Material, the treatment liquid is obtained by compounding ammonium sulfite, trisodium citrate, polyether amine and 40% ethanol aqueous solution with a mass ratio of 2:5:1:12;

[0030] S2. Send the treatment material obtained by drying in step S1 into a shaving machine to make shavings of the required size, use high-temperature flue gas drying technology, control the drying temperature to 440°C, and dry the shavings until the moisture content is 4.5%;

[0031] S3. According to the mass ratio of 8.5:1, the wood...

Embodiment 3

[0034] A kind of PB board that the present invention proposes prevents the control process of large shavings from being damaged, comprising the following steps:

[0035] S1. Cedar wood is preferred as the main raw material, and it is cut to obtain a cutting material with a size of 100 cm. The cutting material is immersed in the treatment solution for soaking treatment. The temperature of the soaking solution is controlled at 58 ° C, the soaking time is controlled at 3 hours, and then dried for treatment. Material, the treatment solution is obtained by compounding ammonium sulfite, trisodium citrate, polyether amine and 50% aqueous ethanol solution with a mass ratio of 2:5:1:12;

[0036] S2. Send the processed material dried in step S1 into a shaving machine to make shavings of the required size, use high-temperature flue gas drying technology, control the drying temperature to 460°C, and dry the shavings until the moisture content is 6%;

[0037] S3. According to the mass rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com