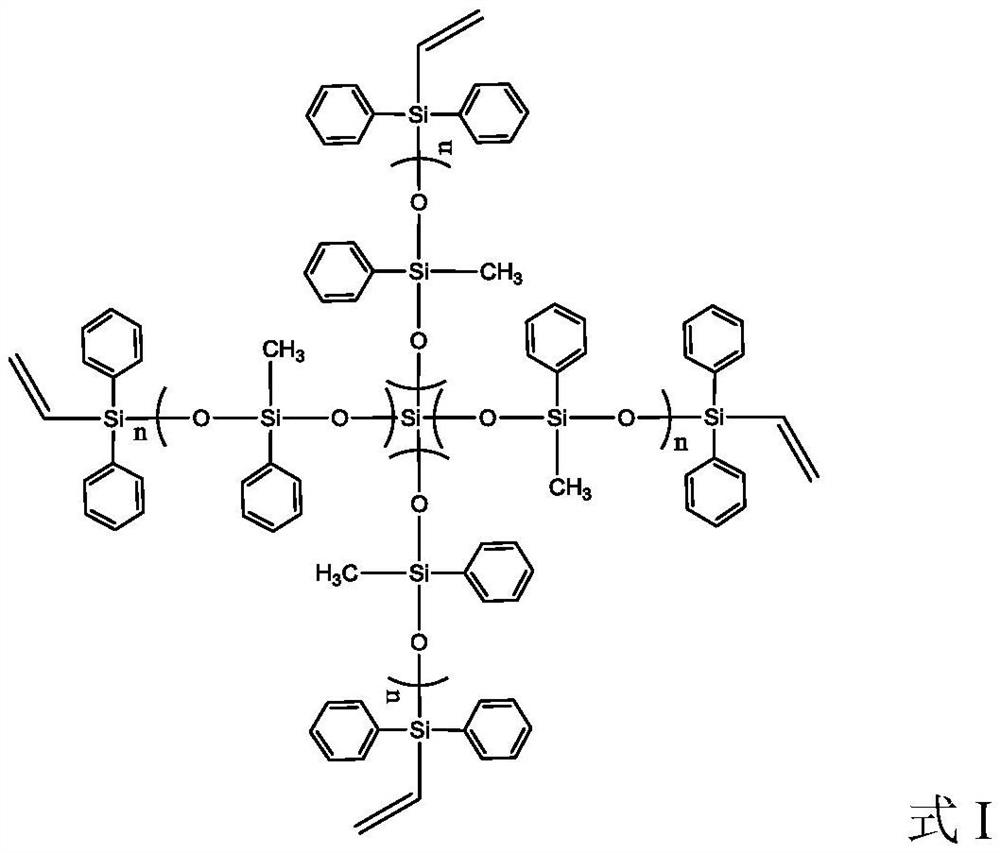

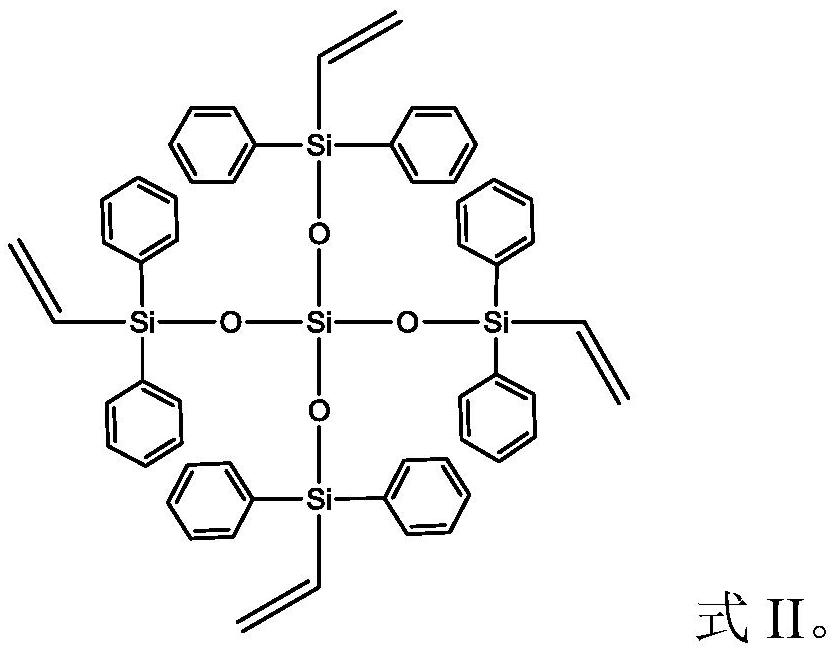

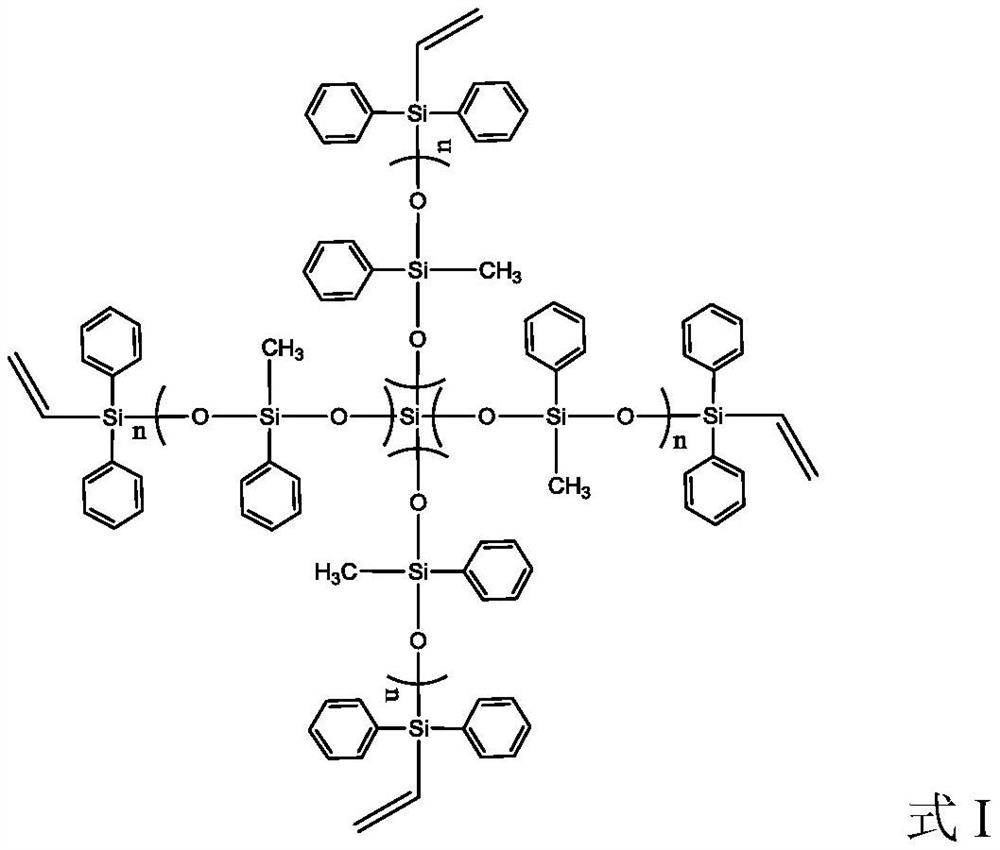

Q-type high-refractive-index phenyl vinyl silicone oil as well as synthesis method and application thereof

A technology of phenylvinyl silicon and synthesis method, which is applied in the direction of adhesives, etc., can solve the problems of difficulty in synthesizing uniform high-refractive silicone oil, poor stability, unfavorable use, etc., and achieve moderate viscosity of the system, good anti-aging performance, suitable for The effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Take a 5000ml three-necked flask, condense and reflux, and protect it with nitrogen. Add 869.36g (2mol) of divinyltetraphenyldimethoxysilane, 208.33g (1mol) of tetraethyl orthosilicate, and 215g of ethanol into the reaction kettle. Slowly add 5.3g of concentrated sulfuric acid dropwise for 30min, raise the temperature to 60°C for equilibrium reaction for 1h, add 45g of deionized water to the reaction system for 30min, continue to react at 60°C for 3h, after the reaction is completed, heat up and steam out the ethanol and excess in the reaction system water until the liquid temperature is 105°C; cool down to 85°C, add 10.42g of acetic acid and 8.69g of divinyltetraphenyldimethoxysilane, continue the reaction for 3h, filter to remove the solid after the reaction, take the filtrate and wash it three times until neutral , and finally 120°C and 10mbar negative pressure to distill out excess water and low volatile matter in the system to obtain vinylmethylphenyl Q-type end-cap...

Embodiment 2

[0082] Take a 5000ml three-neck flask, condense and reflux, protect with nitrogen, add 1086.70g (2.5mol) divinyltetraphenyldimethoxysilane, 208.33g (1mol) tetraethyl orthosilicate, and 388g isopropanol into the reaction kettle, Slowly add 12.95g of concentrated sulfuric acid dropwise at room temperature for 30 minutes, raise the temperature to 70°C for equilibrium reaction for 2 hours, add 36g of deionized water to the reaction system for 30 minutes, and continue to react at 70°C for 5 hours. Ethanol, isopropanol and excess water until the liquid temperature is 105°C, then cool down to 85°C, add 6.2g of acetic acid and 16g of divinyltetraphenyldimethoxysilane, continue the reaction for 3h, filter to remove the solid after the reaction, and take The filtrate was washed three times with water until neutral, and finally excess water and low volatile matter in the system were distilled at 120°C and 10mbar negative pressure to obtain vinylmethylphenyl Q-type end-capping agent. The v...

Embodiment 3

[0084] Take a 5000ml three-necked flask, condense and reflux, and protect it with nitrogen. Add 869.36g (2mol) of divinyltetraphenyldimethoxysilane, 208.33g (1mol) of tetraethyl orthosilicate, and 215g of ethanol into the reaction kettle. Slowly add 5.3g of phosphoric acid for 30 minutes, raise the temperature to 75°C for equilibrium reaction for 1.5h, add 45g of deionized water to the reaction system for 1h, continue to react at 75°C for 4h, after the reaction is completed, heat up and steam out the ethanol and excess in the reaction system water, until the liquid temperature is 105°C, cool down to 80°C, add 14.5g of acetic acid and 8.69g of divinyltetraphenyldimethoxysilane, continue the reaction for 3h, filter to remove the solid after the reaction, take the filtrate and wash it three times until neutral , and finally 120°C and 10mbar negative pressure to distill out excess water and low volatile matter in the system to obtain vinylmethylphenyl Q-type end-capping agent. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com