Green color master batch for PPR pipes and pipe fittings and preparation method and application thereof

A green technology for pipe fittings, applied in the field of green color masterbatch for PPR pipe fittings and its preparation, can solve the problems of easy precipitation, poor dispersion, poor weather resistance, etc., and achieve the effects of avoiding agglomeration, difficult precipitation, low temperature brittleness and improved mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

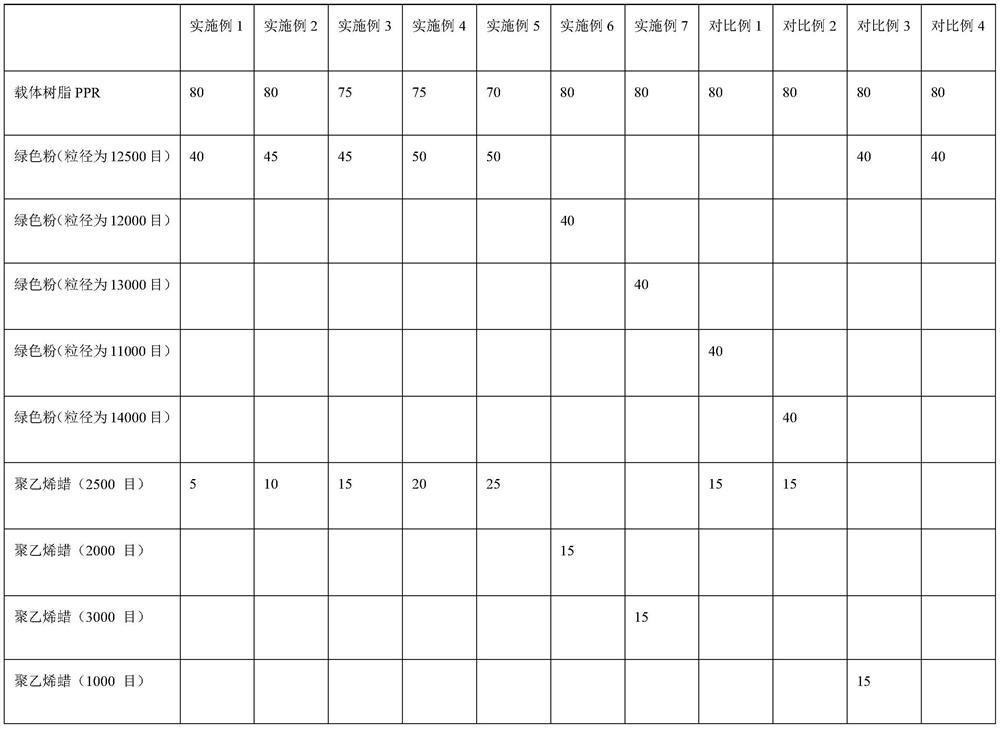

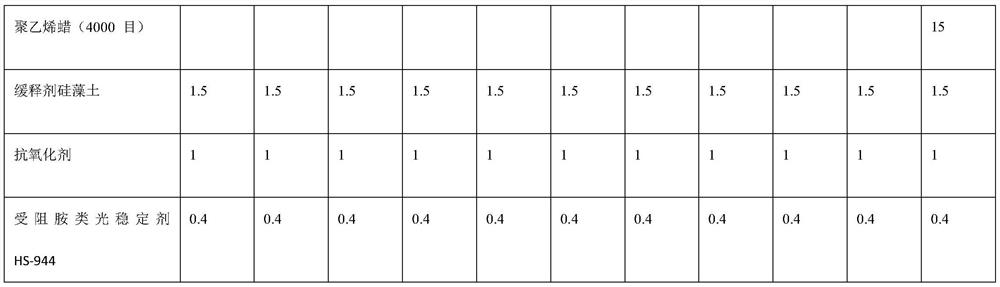

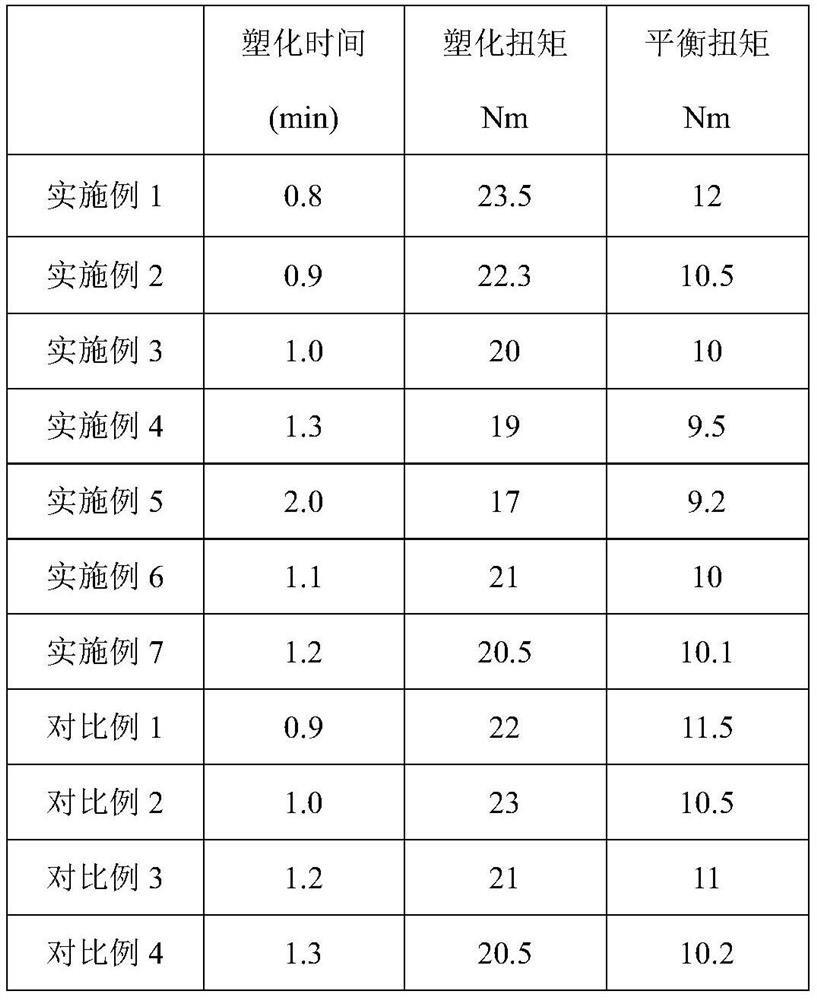

[0047] The green masterbatches for PPR pipes and fittings of Examples 1-5 and Comparative Examples 1-4 include components calculated in parts by weight as shown in Table 1 below, and Examples 2-5 and Comparative Examples 1-4 and Example 1 The difference lies in the replacement of components, and the preparation method is the same.

[0048] Components and consumption (parts) of each embodiment and comparative example of table 1

[0049]

[0050]

[0051] The preparation method of the above-mentioned green color masterbatch for PPR pipe fittings comprises the following steps:

[0052] First, mix the antioxidant, light stabilizer and slow-release agent in proportion, place them in a grinding container, grind them with a high-speed grinder at a speed of 500r / min for 10min, and grind them evenly to obtain the mixed raw materials; add the dispersant and green powder respectively The sand mill disperser grinds at a speed of 2000 rpm, sieves the dispersant grinding particles, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com