Radionuclide decontaminant, and preparation method and application thereof

A radionuclide, detergent technology, applied in chemical instruments and methods, surface active detergent compositions, detergent compounding agents, etc., can solve the problems of uncertainty, waste of materials, complexity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0053] In Examples 1-6, three detergents with different components were respectively prepared by using the preparation method provided by the present invention.

[0054] See Table 1 and Table 2 for the raw material composition of detergent in each embodiment of 1kg.

[0055] Concrete preparation method is as follows:

[0056] Prepare each component according to weight percentage: chelating agent, nuclide removing agent, surfactant, complex enzyme, pH regulator and water;

[0057] Then add water first in the container with stirrer; Add described chelating agent, nuclide removing agent, tensio-active agent and complex enzyme successively to described container under agitation;

[0058] Utilize a stirrer to stir the solution in the container, the stirring speed is 800r / min, and the stirring time is 40min;

[0059] Add an appropriate amount of the pH regulator into the container to adjust the pH value of the solution to 9.0, continue to stir for 15 minutes, mix well, test, and p...

Embodiment 1

[0078] The decontamination effect of the decontamination agents in Examples 1-6 on radioactive contamination can reach more than 83.6%, far exceeding the cleaning effect of clear water. Among them, the decontamination effect of the decontamination agents in Embodiment 1, Embodiment 2 and Embodiment 3 on the radioactive contamination on the surface of the sling is as high as 97%, and has a very strong effect of removing radionuclides.

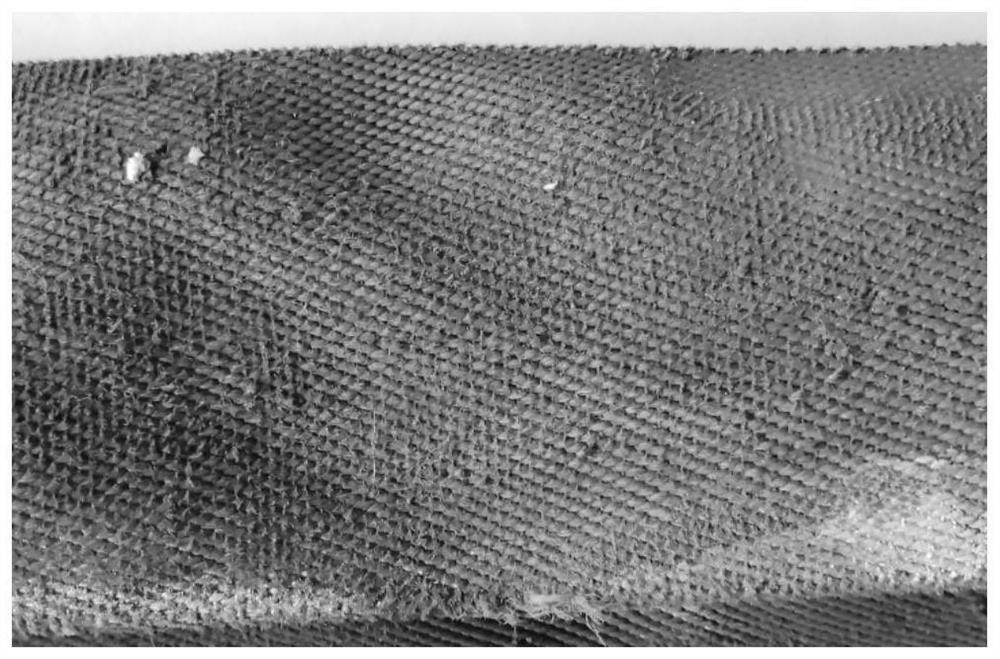

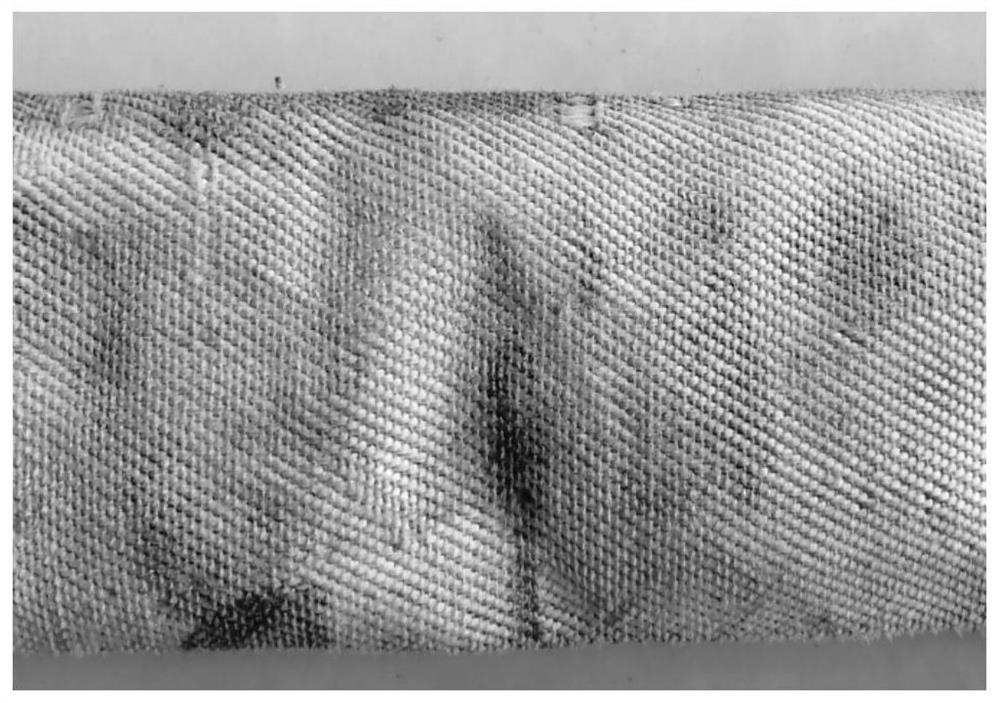

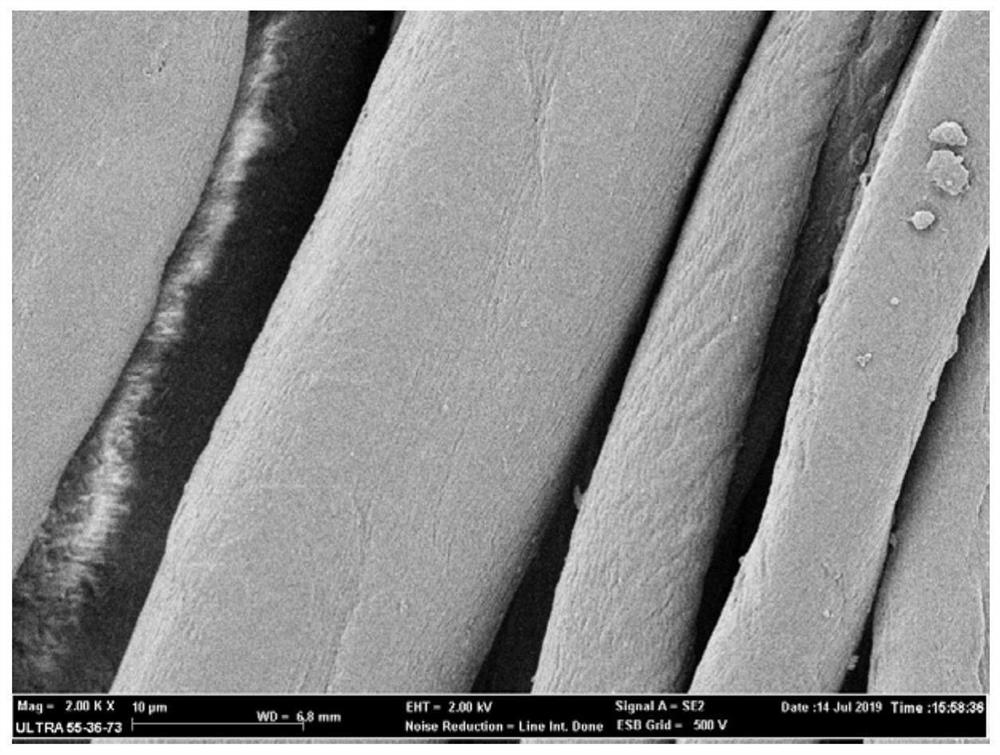

[0079] figure 1 For the photo of the sling before decontamination, figure 2 It is a photo of the sling after the decontamination treatment with the detergent in Example 3. It can be clearly found that the oil stain on the surface of the sling is smoother after the decontamination treatment. image 3 It is the SEM photo of the sling after the decontamination treatment by the detergent in Example 3, which further proves that the decontamination agent in Example 3 has an excellent decontamination effect on the sling without destroying the sling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com