Method for preparing Ti-Al family intermediate phase/Ti-Al-N family MAX phase composite coating on surface of titanium or titanium alloy

A technology of composite coating and mesophase layer, applied in metal material coating process, coating, superimposed layer plating and other directions, can solve the problem of performance mismatch between coating and substrate, to ensure performance and improve bonding degree, the effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

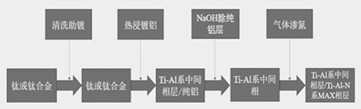

[0028] Such as figure 1 Shown, the preparation method of the present embodiment comprises the following steps:

[0029] Step 1. Use a metal cleaning agent to degrease and clean the surface of the TC4 titanium alloy round rod, and then immerse it in a saturated K 2 ZrF 6 Flux for 2 minutes, take it out and put it in the drying box to dry;

[0030] Step 2. Immerse the TC4 titanium alloy round bar covered with fluxing agent in step 1 in the pure aluminum liquid protected by covering agent KCl:NaCl:NaF=4:3:1 (molar ratio), and control the hot-dip plating temperature to 700°C, keep warm for 3 minutes, and quickly put out water quenching. Form the TiAl required above 3 The thickness of the phase layer is 50 microns;

[0031] Step 3. Immerse the TC4 titanium alloy round rod after hot-dip plating in step 2 in a 10wt.% NaOH hot solution heated in a water bath at 75°C to dissolve the pure aluminum layer and expose TiAl 3 mesophase layer;

[0032] Step 4. Before nitriding, use HF:...

Embodiment 2

[0034] Such as figure 1 Shown, the preparation method of the present embodiment comprises the following steps:

[0035] Step 1. Use a metal cleaning agent to degrease and clean the surface of the TC4 titanium alloy round rod, and then immerse it in a saturated K 2 ZrF 6 Flux for 2 minutes, take it out and put it in the drying box to dry;

[0036] Step 2. Immerse the TC4 titanium alloy round bar covered with fluxing agent in step 1 in the pure aluminum liquid protected by covering agent KCl:NaCl:NaF=4:3:1 (molar ratio), and control the hot-dip plating temperature to 750°C, keep warm for 6 minutes, and quickly put out water quenching. Form the TiAl required above 3 The thickness of the phase layer is 100 microns;

[0037] Step 3. Immerse the TC4 titanium alloy round rod after hot-dip plating in step 2 in a 10wt.% NaOH hot solution heated in a water bath at 75°C to dissolve the pure aluminum layer and expose TiAl 3 mesophase layer;

[0038] Step 4. Before nitriding, use HF...

Embodiment 3

[0040] Such as figure 1 Shown, the preparation method of the present embodiment comprises the following steps:

[0041] Step 1. Use a metal cleaning agent to degrease and clean the surface of the TC4 titanium alloy round rod, and then immerse it in a saturated K 2 ZrF 6 Flux for 2 minutes, take it out and put it in the drying box to dry;

[0042] Step 2. Immerse the TC4 titanium alloy round bar covered with fluxing agent in step 1 in the pure aluminum liquid protected by covering agent KCl:NaCl:NaF=4:3:1 (molar ratio), and control the hot-dip plating temperature to 800°C, keep warm for 9 minutes, and quickly put out water quenching. Form the TiAl required above 3 The thickness of the phase layer is 150 microns;

[0043] Step 3. Immerse the TC4 titanium alloy round rod after hot-dip plating in step 2 in a 10wt.% NaOH hot solution heated in a water bath at 75°C to dissolve the pure aluminum layer and expose the TiAl 3 mesophase layer;

[0044] Step 4. Before nitriding, us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com