A kind of growth method and application of high-temperature phase lanthanum borosilicate crystal

A growth method and crystal growth technology, applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of difficult to obtain high temperature phase, small crystal size, etc., and achieve the effect of wide use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

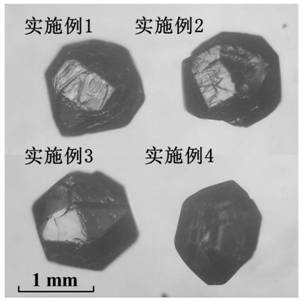

[0037] Example 1: Spontaneous Nucleation Growth of β-La 0.92 Eu 0.08 BSiO 5 crystal

[0038] According to (La 0.92 Eu 0.08 )BO 3 :LiMoO 4 :SiO 2 :B 2 O 3 =0.2:0.75:0.05:0.05(mol) ratio for ingredients, weigh La 2 O 3 , Eu 2 O 3 , H 3 BO 3 , SiO 2 , Li 2 CO 3 and MoO 3 Wait for the raw materials, fully grind and mix the raw materials with a total weight of 20g in an agate mortar and mix them evenly, put them into a platinum crucible, and then transfer them to a high-temperature molten salt furnace. The melt reacted completely, and then dropped to 800°C at a cooling rate of 120°C / day. After the crystal growth was completed, it was rapidly annealed to room temperature, and the crystal was taken out, washed and dried to obtain transparent β-La 0.92 Eu 0.08 BSiO 5 The single crystal is about 1.5mm in size, and its phase can be determined to be a high temperature phase by X-ray diffraction technology.

Embodiment 2

[0039] Example 2: Spontaneous Nucleation Growth of β-La 0.9 Nd 0.1 BSiO 5 crystal

[0040] According to (La 0.9 Nd 0.1 )BO 3 :LiMoO 4 :SiO 2 :B 2 O 3 =0.1:0.8:0.1:0.025(mol) ratio for ingredients, weigh La 2 O 3 , Nd 2 O 3 , H 3 BO 3 , SiO 2 , Li 2 CO 3 and MoO 3 Wait for the raw materials, fully grind and mix the raw materials with a total weight of 30g in an agate mortar and mix them evenly, put them into a platinum crucible, and then transfer them to a high-temperature molten salt furnace. The melt was completely reacted, and then lowered to 750°C at a cooling rate of 240°C / day. After the crystal growth was completed, it was rapidly annealed to room temperature. The crystal was taken out, washed and dried to obtain transparent β-La 0.9 Nd 0.1 BSiO 5 The single crystal is about 1.6mm in size, and its phase can be determined to be a high temperature phase by X-ray diffraction technology.

Embodiment 3

[0041] Example 3: Spontaneous Nucleation Growth of β-La 0.8 Nd 0.2 BSiO 5 crystal

[0042] According to (La 0.8 Nd 0.2 )BO 3 :LiMoO 4 :SiO 2 :B 2 O 3 =0.22:0.7:0.08:0.055(mol) ratio for ingredients, weigh La 2 O 3 , Nd 2 O 3 , H 3 BO 3 , SiO 2 , Li 2 CO 3 and MoO 3 Wait for the raw materials, fully grind and mix the raw materials with a total weight of 25g in an agate mortar and mix them evenly, put them into a platinum crucible, and then transfer them to a high-temperature molten salt furnace. The melt was completely reacted, and then lowered to 850°C at a cooling rate of 360°C / day. After the crystal growth was completed, it was rapidly annealed to room temperature. The crystal was taken out, washed and dried to obtain transparent β-La. 0.8 Nd 0.2 BSiO 5 The single crystal is about 1.8mm in size, and its phase can be determined to be a high temperature phase by X-ray diffraction technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com