Dyeing process of cyclically regenerated high-density polyamide cool fabric

A technology of recycling and craftsmanship, applied in the field of textile printing and dyeing, can solve the problems of low fiber linear density, fast adsorption speed, easy to produce color flowers, etc., achieve good absorption effect, good effect, and delay the effect of dyeing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Fabric gray fabric: recycled high-density nylon fabric made of recycled 20D / 24F nylon filament and low elastic yarn.

[0024] The regenerated nylon used in the fabric comes from waste nylon screens, carpets, etc., which are obtained through depolymerization and repolymerization processes, regenerated granulation, slicing, and spinning.

[0025] After the above-mentioned fabric gray cloth passes through the pretreatment process, it enters the dyeing process stage.

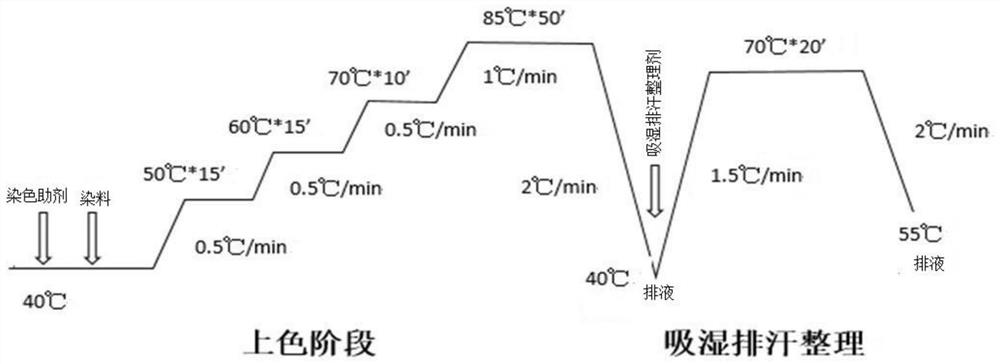

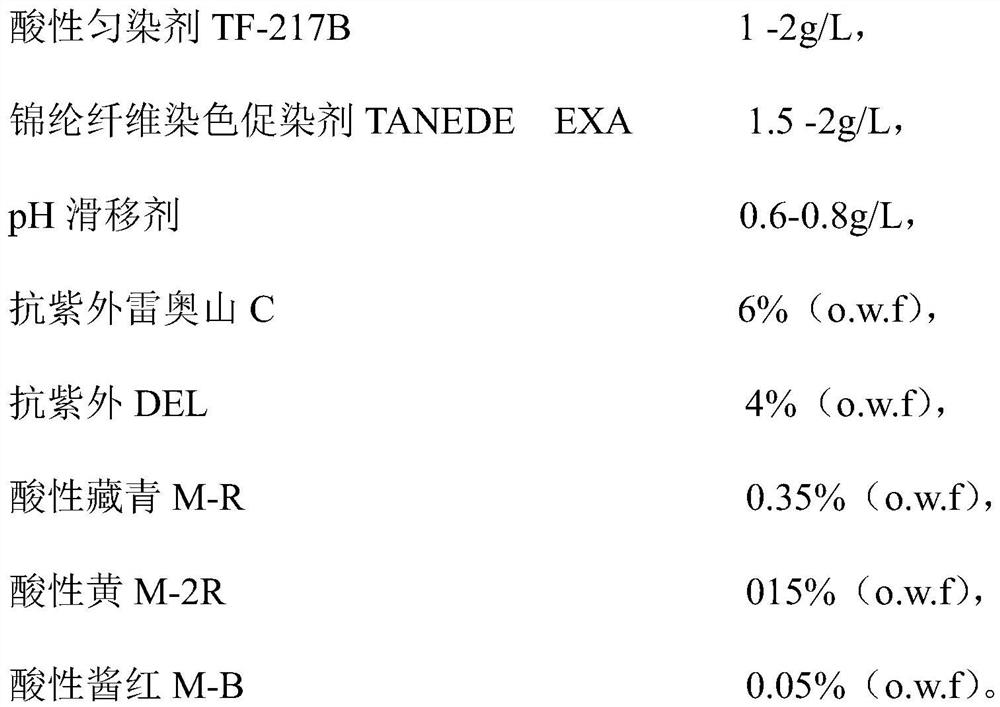

[0026] The dyeing process of recycled high-density nylon cool fabric includes a coloring stage and a moisture-wicking finishing stage; the dyeing agent used in the coloring stage includes dyeing auxiliaries and acid dyes; after the coloring stage is completed, the liquid is drained, and then moisture-wicking finishing is added moisture absorption and perspiration finishing; the dyeing auxiliaries include acid leveling agent TF-217B, nylon fiber dyeing accelerator TANEDE EXA, pH slip agent, anti-ultraviolet Le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com