Corn kernel string production line

A production line and corn kernel technology, applied in food forming, food science, application, etc., can solve the problems of increased cost, decreased freshness of corn kernels, long slowing time, etc., to increase production quantity and speed, and nutritional value The effect of not losing and increasing the freshness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is further described below through specific examples, but the present invention is not limited only to the following examples. Within the scope of the present invention or without departing from the content, spirit and scope of the present invention, changes, combinations or substitutions to the present invention are obvious to those skilled in the art and are included in the scope of the present invention Inside.

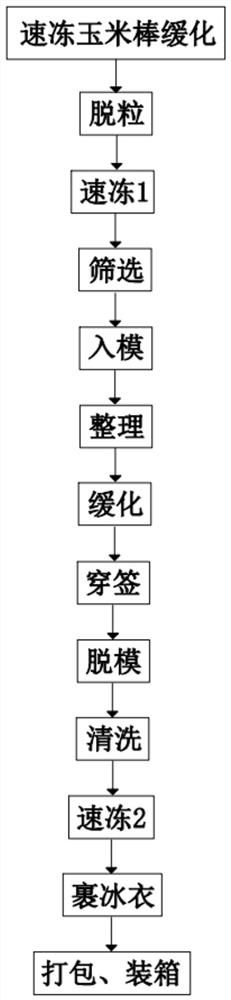

[0026] A production line for corn kernel strings, comprising the following steps:

[0027] (1) Mitigation of quick-frozen corn cobs: mitigation temperature: 15-40°C, mitigation time: 3-8 hours;

[0028] (2) threshing: use a thresher to thresh the corn cobs slowed down in step (1);

[0029] (3) Quick-freezing 1: enter the quick-freezing chamber after threshing, quick-freezing temperature: minus 18°C to minus 34°C, quick-freezing time: 2-8 hours;

[0030] (4) Screening: use a screening machine to carry out hierarchical screening of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com