3D printing individualized customized bionic micropore acetabulum mortise and tenon patch and manufacturing method

A 3D printing and patch technology, applied in the field of acetabular reconstruction patch, can solve the problems of increasing the bone volume around the hip, collapse, and the defect of the acetabulum cannot be well matched, etc., to increase the strength of mechanical support, improve the structural design, The effect of good human compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

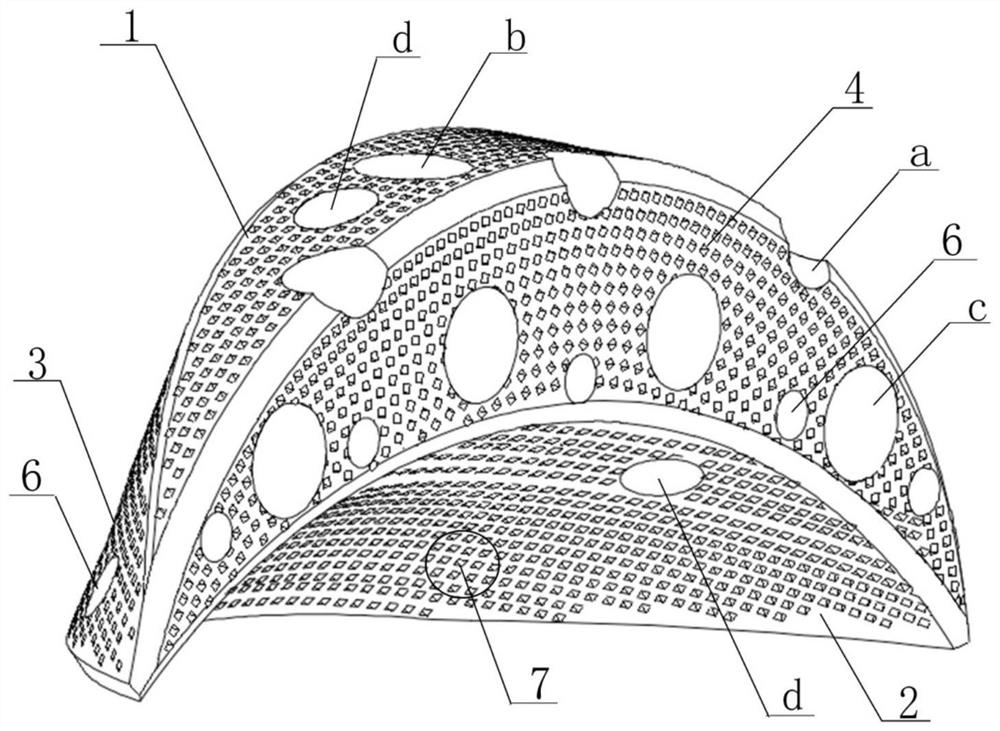

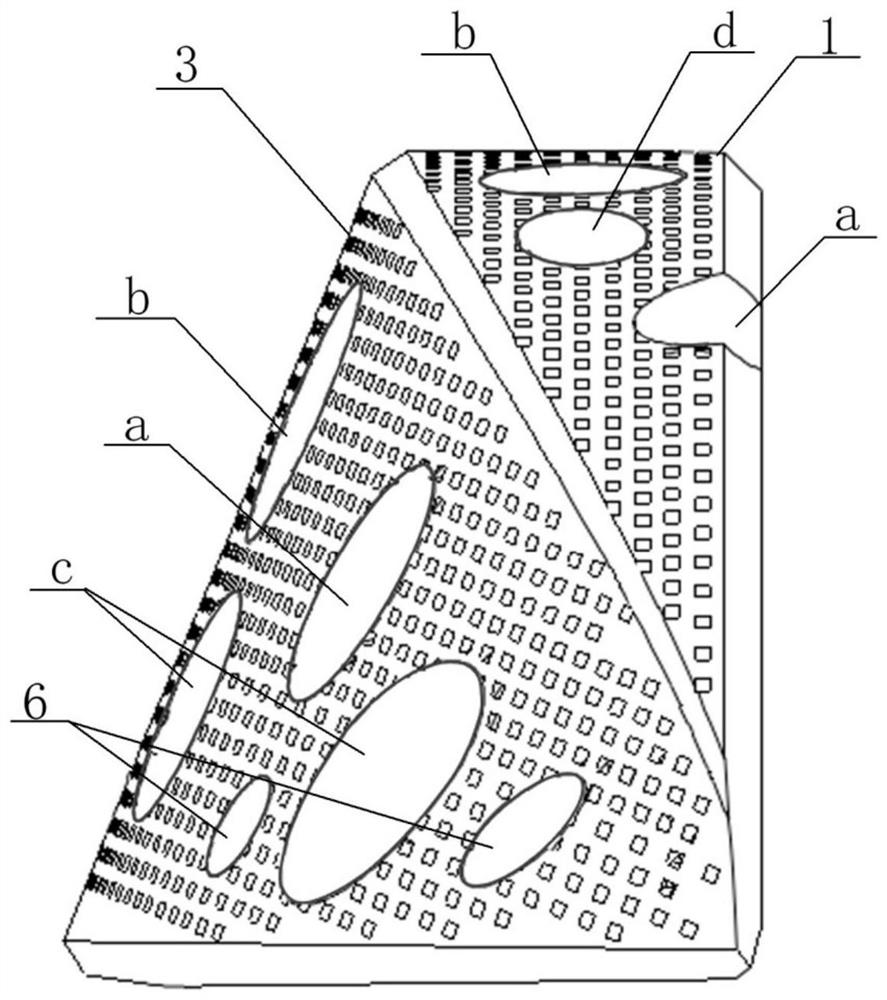

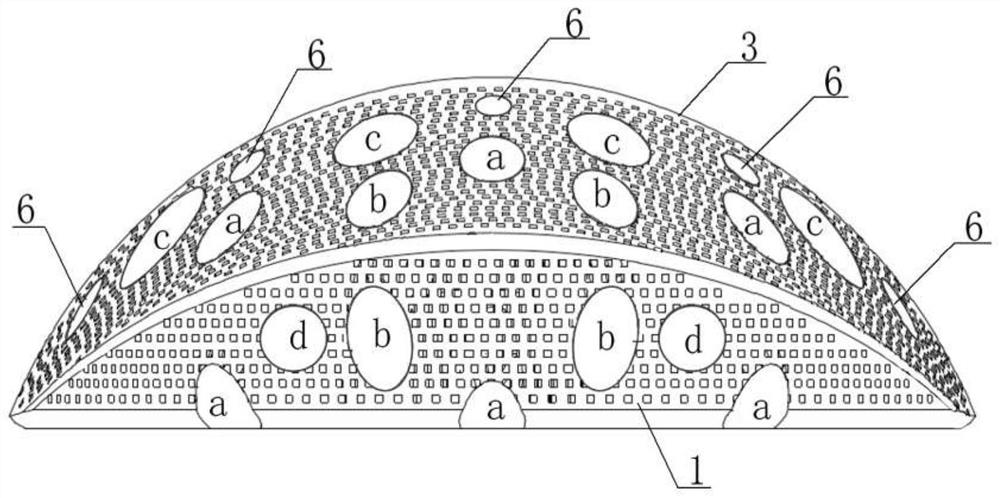

[0041] see Figure 1-6 Shown:

[0042] The present invention provides a 3D printed individualized customized bionic microporous acetabular mortise and tenon patch. The mortise and tenon patch is a 3D printed solid structure, and the outer surface includes an upper surface 1, a lower surface 2, an outer surface 3 and an inner surface. Side 4, wherein the upper and lower edges of the inner side 4 are in contact with one side of the upper surface 1 and the lower surface 2 respectively, and the angle between the upper surface and the inner side is 75° or 90° or 105° or 120° , forming a mortise and tenon structure embedded in the acetabular bone defect; the upper and lower edges of the outer surface 3 are respectively connected to the other side of the upper surface 1 and the lower surface 2, and are surrounded by an integral mortise and tenon patch structure; this embodiment The inner surface 4 of the mortise and tenon patch is a crescent-shaped structure, and the lower surface 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com