A kind of acrylate rubber material and preparation method thereof, heat shrinkable sleeve

A rubber material and acrylate technology, applied in the field of materials, can solve the problems of oil resistance, high/low temperature resistance, poor softness, etc., and achieve the effect of low cost, excellent oil resistance, and rich application types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

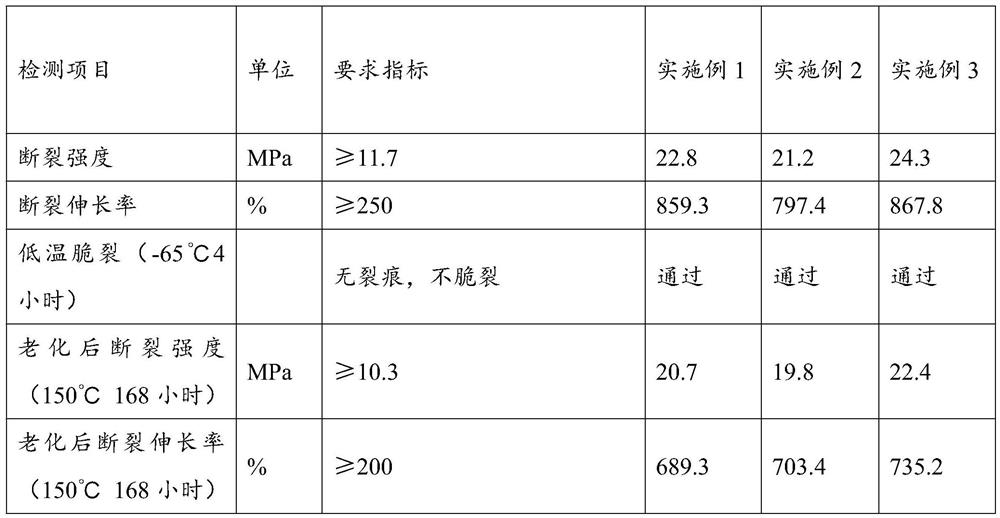

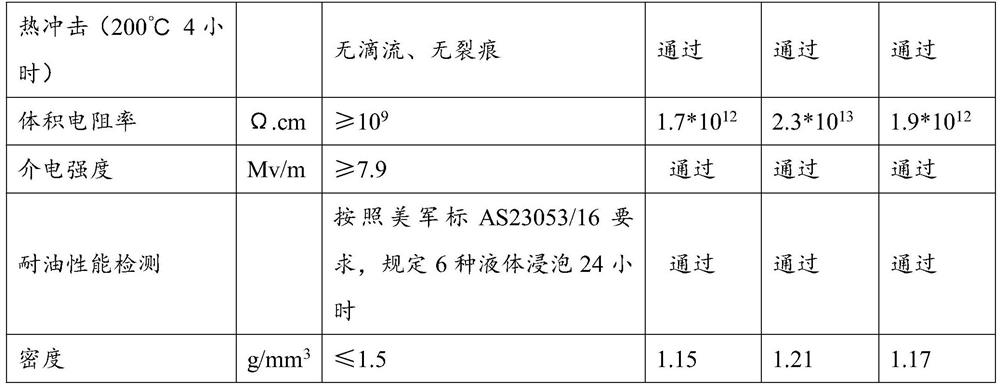

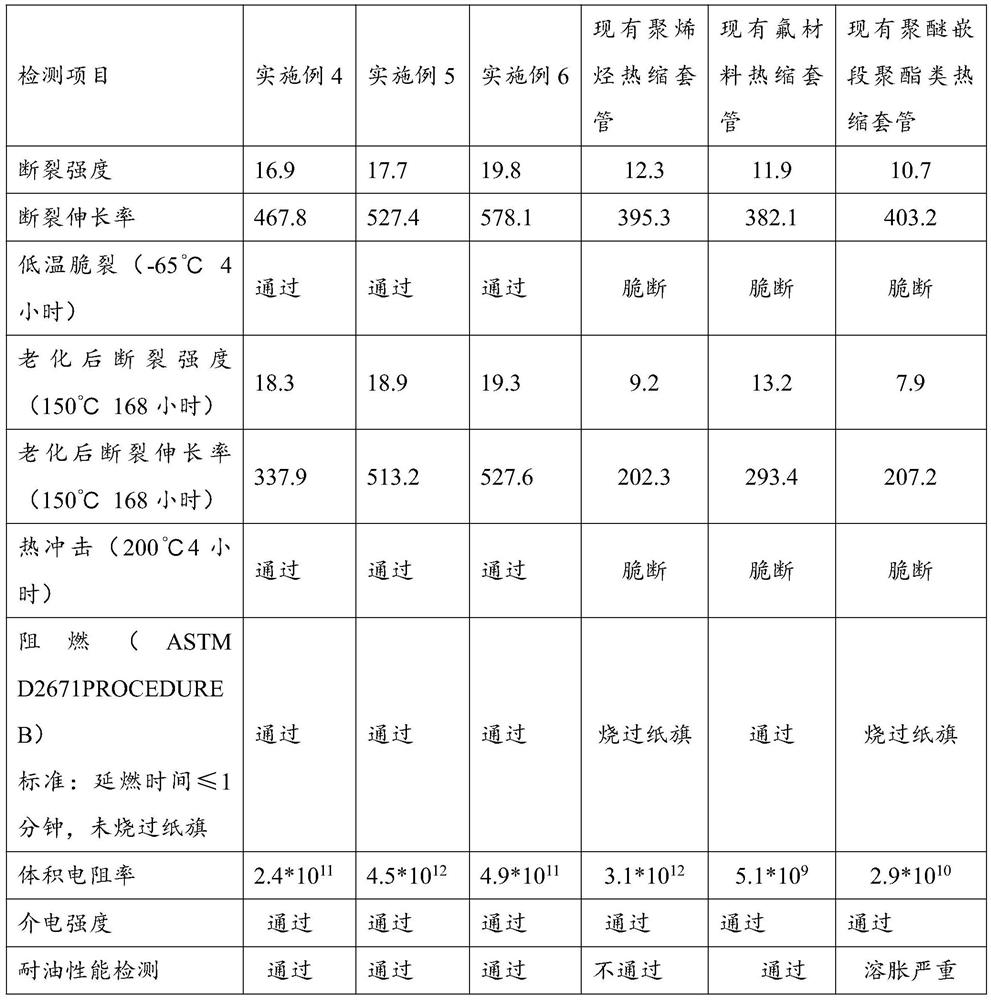

Examples

preparation example Construction

[0030] The preparation method of the acrylate rubber material provided by the embodiment of the present invention comprises the following steps:

[0031] Step S1: Weigh each raw material according to the above-mentioned formula of the acrylate rubber material, and set aside.

[0032] Step S2: put the polyacrylate rubber, polyvinyl acetate rubber, metal ion polymer resin, lubricant, anti-aging agent and reinforcing agent into an internal mixer for pressure kneading treatment to obtain a mixed rubber.

[0033] In the embodiment of the present invention, when it is necessary to impart flame retardant properties and / or antibacterial properties to the material, the flame retardant and / or flame retardant synergist and / or antibacterial agent with flame retardant properties can be put into the corresponding Pressurized kneading is carried out in the internal mixer; similarly, when the material needs to be given pigment, the corresponding toner is added according to the actual material...

Embodiment 1

[0042] The acrylate rubber material in this embodiment is made up of the following raw materials:

[0043]Polyacrylate rubber 85Kg (specifically, VAMAC series DP 35Kg and DHC 50Kg of DUPONT), 5Kg polyvinyl acetate rubber (specifically, 5Kg of Levapren series 500 of LANXESS company), metal ion polymer resin 10Kg (specifically, DUPONT's surlyn series 1706 brand 10Kg), lubricant 1Kg (specifically take octadecyl primary amine ARMEEN D, polyoxyethylene octadecyl ether phosphate VAM each 0.5Kg), anti-aging agent 1Kg (specifically take 4010, KY405 each 0.5Kg) and Reinforcing agent 10Kg (specifically take white carbon black 10Kg).

[0044] Preparation process of acrylate rubber material:

[0045] According to the formula of the above-mentioned acrylate rubber material, each raw material is weighed for subsequent use; polyacrylate rubber, polyvinyl acetate rubber, metal ion polymer resin, lubricant, anti-aging agent and reinforcing agent are respectively put into the internal mixer, ...

Embodiment 2

[0047] The acrylate rubber material in this embodiment is made up of the following raw materials:

[0048] Polyacrylate rubber 75Kg (specifically take ZEON's HyTemp series AR14 brand 45Kg, AR12 brand 30Kg), polyvinyl acetate rubber 10Kg (specifically take LANXESS company Levapren series 500, 600 brand each 5Kg), metal ion polymer resin 15Kg (specifically Take DUPONT's surlyn series 1706 brand 15Kg), lubricant 4Kg (specifically take octadecyl primary amine ARMEEN D, polyoxyethylene octadecyl ether phosphate VAM each 2Kg), anti-aging agent 4Kg (specifically take 4010, KY405 each 2Kg) and reinforcing agent 30Kg (specifically take white carbon black 30Kg).

[0049] Preparation process of acrylate rubber material:

[0050] According to the formula of the above-mentioned acrylate rubber material, each raw material is weighed for subsequent use; polyacrylate rubber, polyvinyl acetate rubber, metal ion polymer resin, lubricant, anti-aging agent and reinforcing agent are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com