Polydimethylsiloxane-based liquid metal bridged spherical boron nitride heat-conducting composite material as well as preparation method and application thereof

A polydimethylsiloxane-based, thermally conductive composite material technology, applied in the field of thermal interface materials, can solve problems such as environmental protection, short circuit of electronic components, and reduce gallium usage, achieving high thermal conductivity, good mechanical properties, The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

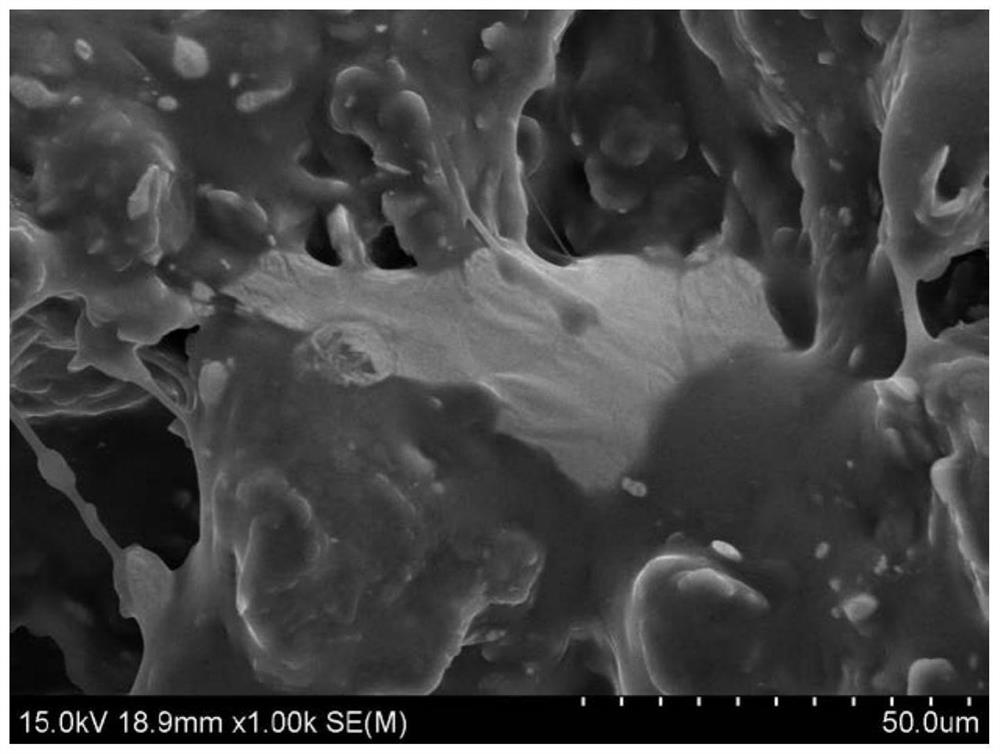

Image

Examples

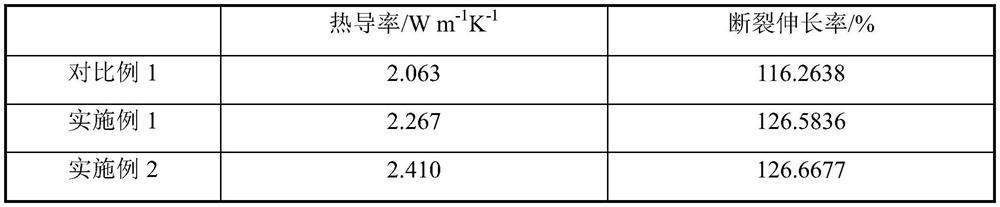

Embodiment 1

[0030] A polydimethylsiloxane-based liquid metal bridged spherical boron nitride heat-conducting composite material, comprising the following components:

[0031] Silicone oil 14.97g

[0032] Spherical boron nitride 15g

[0033] Gallium Indium Alloy 5g

[0034] Catalyst 0.03g;

[0035] Wherein, the silicone oil is composed of vinyl silicone oil, hydrogen-containing silicone oil and inhibitor in a mass ratio of 2500:500:1, and the vinyl silicone oil is selected from RH-100 of Zhejiang Runhe Organic Silicon New Material Co., Ltd.; The hydrogen-containing silicone oil is selected from RH-35 and RH-H6 of Zhejiang Runhe Silicone New Material Co., Ltd., wherein the mass ratio of RH-35 and RH-H6 is 4:5; the inhibitor is 2-phenyl-3 -butyn-2-ol;

[0036] The average particle size of the spherical boron nitride is 90 μm;

[0037] The gallium-indium alloy is a Ga:In mass ratio of 3:1;

[0038] The catalyst is CAT-PL-56.

[0039] The preparation process of the polydimethylsiloxane-...

Embodiment 2

[0044] A polydimethylsiloxane-based liquid metal bridged spherical boron nitride heat-conducting composite material, comprising the following components:

[0045] Silicone oil 14.97g

[0046] Spherical boron nitride 15g

[0047] Gallium Indium Alloy 10g

[0048] Catalyst 0.03g;

[0049] Wherein, the silicone oil is composed of vinyl silicone oil, hydrogen-containing silicone oil and inhibitor in a mass ratio of 2500:500:1, and the vinyl silicone oil is selected from RH-100 of Zhejiang Runhe Organic Silicon New Material Co., Ltd.; The hydrogen-containing silicone oil is selected from RH-35 and RH-H6 of Zhejiang Runhe Silicone New Material Co., Ltd., wherein the mass ratio of RH-35 and RH-H6 is 4:5; the inhibitor is 2-phenyl-3 -butyn-2-ol;

[0050] The average particle size of the spherical boron nitride is 90 μm;

[0051] The gallium-indium alloy is a Ga:In mass ratio of 3:1;

[0052] The catalyst is CAT-PL-56.

[0053] The preparation process of the polydimethylsiloxane...

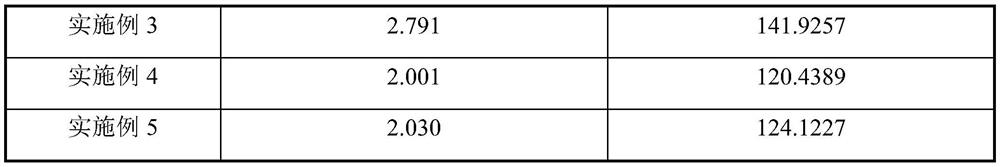

Embodiment 3

[0058] A polydimethylsiloxane-based liquid metal bridged spherical boron nitride heat-conducting composite material, comprising the following components:

[0059] Silicone oil 14.97g

[0060] Spherical boron nitride 15g

[0061] Gallium Indium Alloy 15g

[0062] Catalyst 0.03g;

[0063] Wherein, the silicone oil is composed of vinyl silicone oil, hydrogen-containing silicone oil and inhibitor in a mass ratio of 2500:500:1, and the vinyl silicone oil is selected from RH-100 of Zhejiang Runhe Organic Silicon New Material Co., Ltd.; The hydrogen-containing silicone oil is selected from RH-35 and RH-H6 of Zhejiang Runhe Silicone New Material Co., Ltd., wherein the mass ratio of RH-35 and RH-H6 is 4:5; the inhibitor is 2-phenyl-3 -butyn-2-ol;

[0064] The average particle size of the spherical boron nitride is 90 μm;

[0065] The gallium-indium alloy is a Ga:In mass ratio of 3:1;

[0066] The catalyst is CAT-PL-56.

[0067] The preparation process of the polydimethylsiloxane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com