Heat-conducting gasket and preparation method thereof

A technology of thermally conductive gaskets and thermally conductive fillers is applied in the fields of thermal management materials, thermally conductive interface materials, and thermally conductive and heat-dissipating materials. high coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

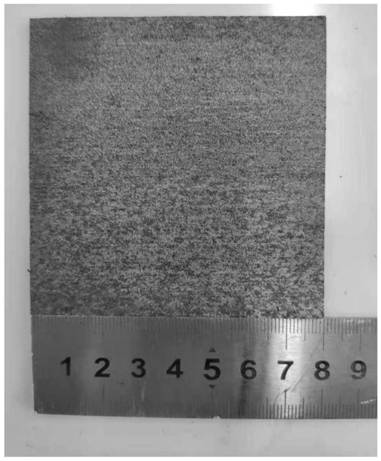

[0047] Such as Figure 7 As shown, 95wt.% graphite sheet and 5wt.% reinforcing material, wherein the reinforcing material is a polymer filament, can still be directly pressed and formed without a binder, and the formability is good.

Embodiment 2

[0055] In this embodiment, graphene accounts for 50wt.%, polymer filaments account for 0.3wt.%, and liquid silica gel accounts for 49.7wt.%.

[0056] The ratio of graphene sheet size distribution between 10-100 μm and 100-1000 μm is 0.1;

[0057] The high molecular polymer used for wire drawing is PE;

[0058] Liquid silicone is polydimethylcyclosiloxane;

[0059] High speed shear drawing rate 50000r / min; shear time 0.5min;

[0060] After adding liquid silica gel and mixing thoroughly, the thickness of the prepared sheet is 0.2mm;

[0061] The curing temperature is 150°C;

[0062] After testing, the thermal conductivity of the sample is 15.4W / (m K), and the application thermal resistance and compression resilience results of samples with different thicknesses are shown in Table 1:

[0063] Table 1

[0064] Thickness (mm) Applied Thermal Resistance (K in 2 / W)

Embodiment 3

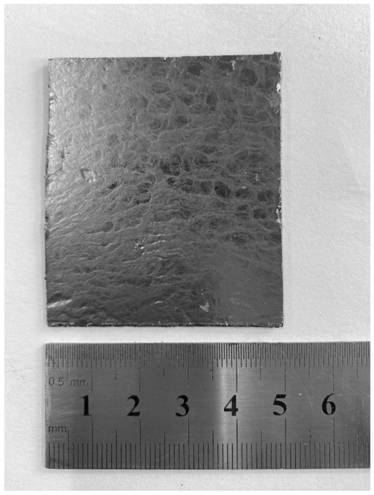

[0066] In this embodiment, graphene accounts for 90wt.%, polymer filaments account for 2wt.%, and liquid silica gel accounts for 8wt.%.

[0067] The ratio of graphene sheet size distribution between 10-100μm and 100-1000μm is 9.0;

[0068] The high molecular polymer used for wire drawing is PP;

[0069] Liquid silicone is polydimethylsiloxane;

[0070] High-speed shearing machine shearing and drawing speed 1000r / min; shearing time 6min;

[0071] After adding liquid silica gel and mixing thoroughly, the thickness of the prepared sheet is 3mm;

[0072] The curing temperature is 120°C;

[0073] After testing, the thermal conductivity of the sample is 47.3W / (m K), and the application thermal resistance and compression resilience results of samples with different thicknesses are shown in Table 2:

[0074] Table 2

[0075]

[0076]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com