High-voltage motor non-electric quantity protection measurement and control device and protection measurement and control method

A non-electricity protection, measurement and control device technology, applied in the direction of motor generator testing, electrical testing/monitoring, testing/monitoring control systems, etc., can solve the problem that non-electricity monitoring and protection have not kept up, are not absolutely safe and reliable, and cannot be achieved and other issues, to achieve safe and reliable long-term operation, ensure safe and reliable operation, and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

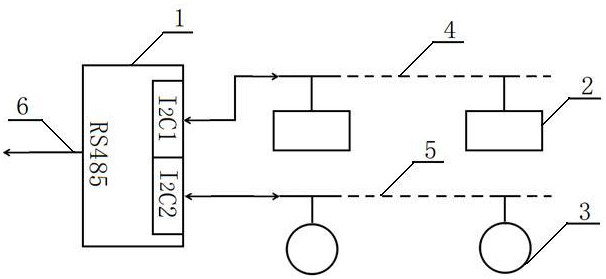

[0025] A high-voltage motor non-electrical protection measurement and control device, which consists of: a display terminal 2, the number of the display terminal and the local terminal 3 are each in a group, and there is a one-to-one correspondence, each of the display terminals and the The local terminals each have a unique address code, and the control terminal 1 is connected with the display terminal and the local terminal through this unique address code and transmits instructions or data, and the control terminals are connected through the relay I2C The bus A4 and the relay I2C bus B5 are sequentially connected to a group of display terminals and a group of local terminals, and the control terminal is connected to the remote distributed control system through the RS485 bus 6 .

Embodiment 2

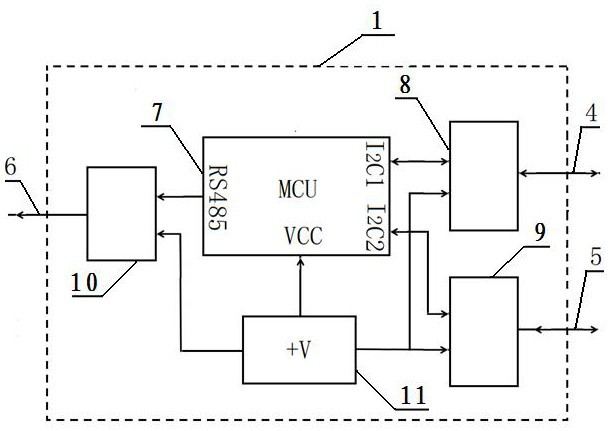

[0027] According to the high-voltage motor non-electrical protection measurement and control device described in Embodiment 1, the control terminal includes a control terminal microprocessor 7, and the control terminal microprocessor is respectively connected with the control-local I2C bus repeater 8, the control -On-site I2C bus repeater 9, DC power supply 11, RS485 communicator 10 are connected, and described RS485 communicator is respectively connected with described DC power supply, described RS485 bus line, and described DC power supply is respectively connected with described The control-local I2C bus repeater, the control-local I2C bus repeater is connected, the control-local I2C bus repeater is connected with the relay I2C bus A, the The control-local I2C bus repeater is connected with the repeater I2C bus B.

Embodiment 3

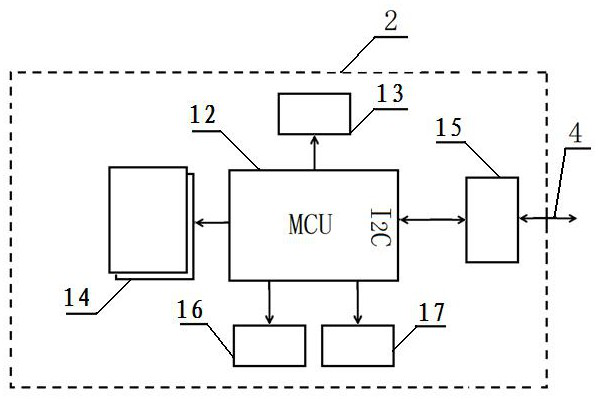

[0029] According to the high-voltage motor non-electrical protection measurement and control device described in Embodiment 1, the display terminal includes a display terminal microprocessor 12, and the display terminal microprocessor is connected with the Bluetooth module 13, the liquid crystal display screen 14, and the display-control I2C bus repeater 15, audio device 16, protection outlet 17 is connected, and described display-control I2C bus repeater is connected with described relay I2C bus A, and described local terminal comprises local terminal microprocessor 18. The on-site terminal microprocessor is connected with on-site-control I2C bus repeater 19, infrared imaging I2C bus repeater 22, audio preamplifier 27, instrument amplifier 20, bearing vibration sensor 25 respectively, so The instrumentation amplifier described above is connected with the stator winding temperature sensor 23 and the bearing temperature sensor 24 respectively, the described local-control I2C bus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com