Processing method of high aspect ratio metallized blind hole

A technology of metallized blind holes and processing methods, applied in the field of circuit board manufacturing, can solve the problems of poor hole consistency, small bottom of metallized blind holes, unprotected metallized blind holes, etc., to ensure qualified and consistent size sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

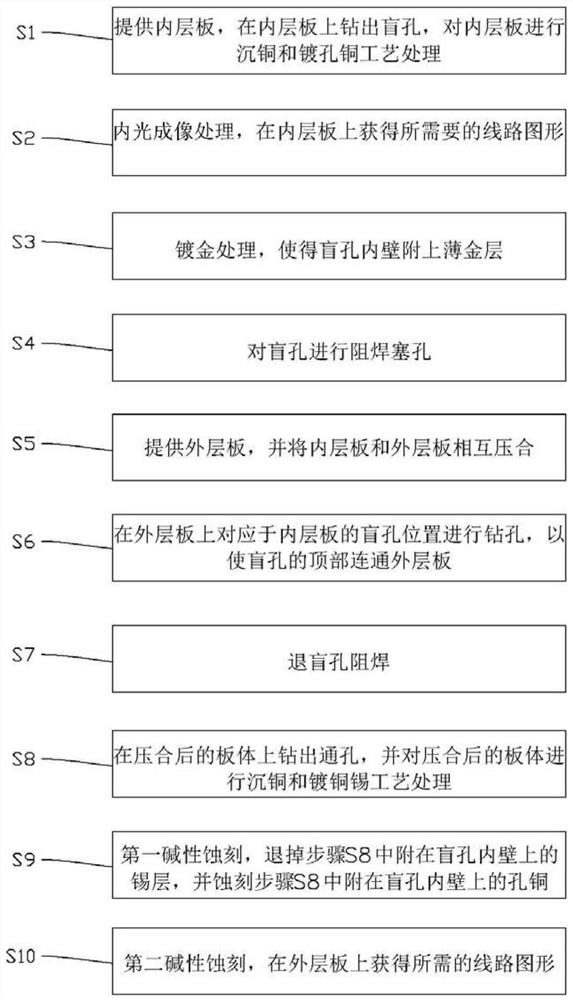

[0017] Embodiments of the present invention are described in detail below, referring to figure 1 , an embodiment of the present invention provides a processing method of a high aspect ratio metallized blind hole, comprising the following steps:

[0018] S1. Provide an inner layer board, and drill blind holes on the inner layer board, and process the inner layer board with copper immersion and plated hole copper, so that the blind hole is plated with copper layer, so that the upper and lower surfaces of the inner layer board can be connected;

[0019] S2, internal light imaging processing, obtain the required circuit pattern on the inner layer board, after the circuit pattern is made, the inner layer board is subjected to AOI inspection, and after the inspection is qualified, the next step is entered;

[0020] S3. Gold plating, so that a thin gold layer is attached to the inner wall of the blind hole to protect the copper layer plated in the blind hole;

[0021] S4. Solder th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com