Multi-root implant tooth structure and manufacturing method thereof

A technology for dental implants and tooth roots, applied in the directions of dental implants, additive manufacturing, manufacturing tools, etc., can solve the problems of increasing the risk of infection in patients requiring technical operations, affecting the healing process of peri-implant bone, and difficulty in ensuring initial stability, etc. Achieve the effect of reducing technical operation requirements and the risk of postoperative infection of patients, improving the success rate of implantation, and simplifying the clinical treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

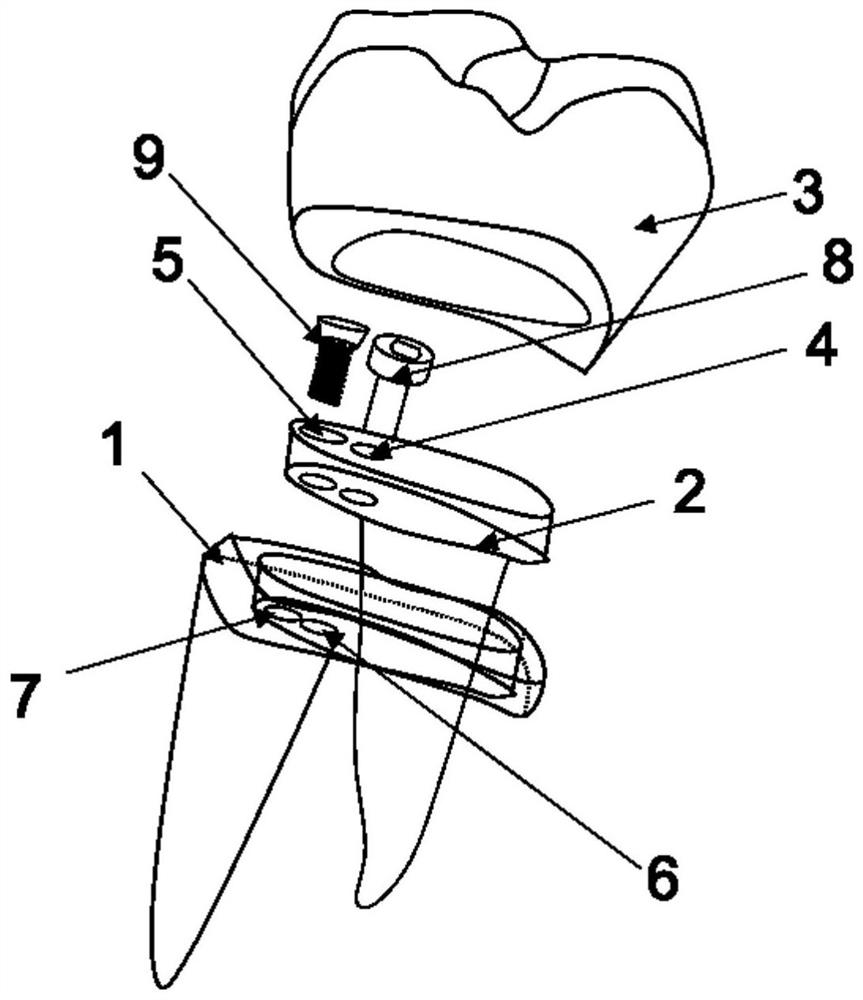

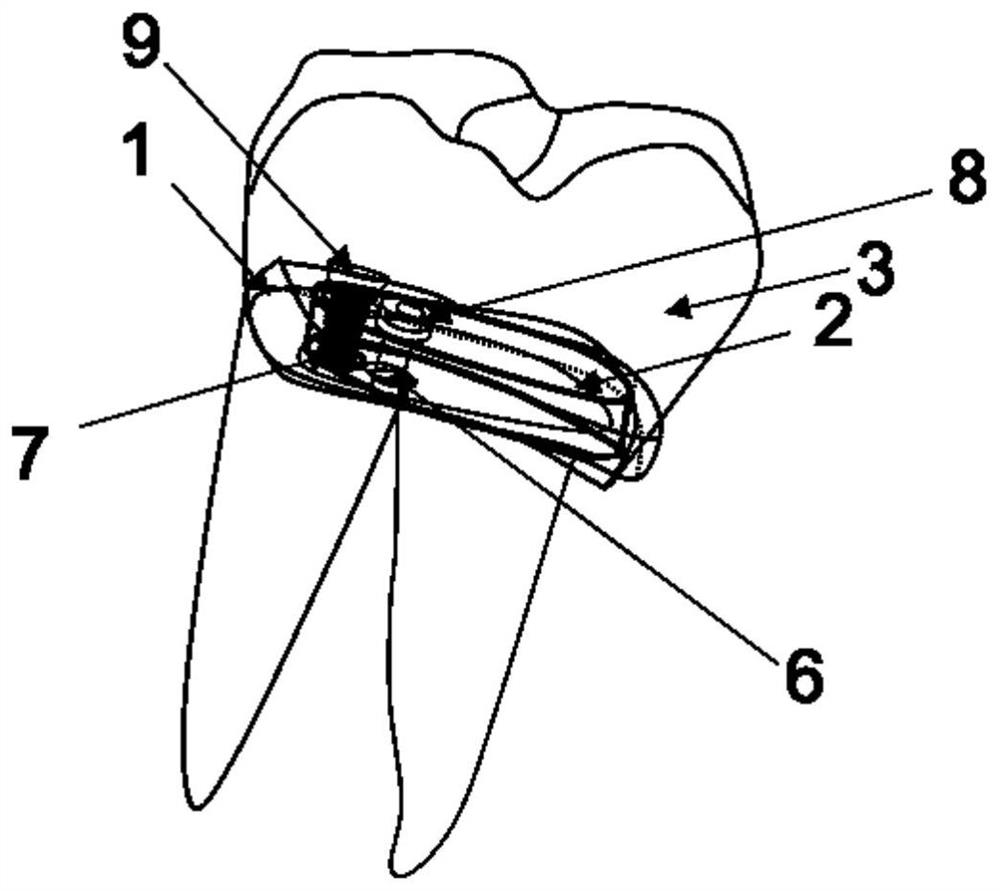

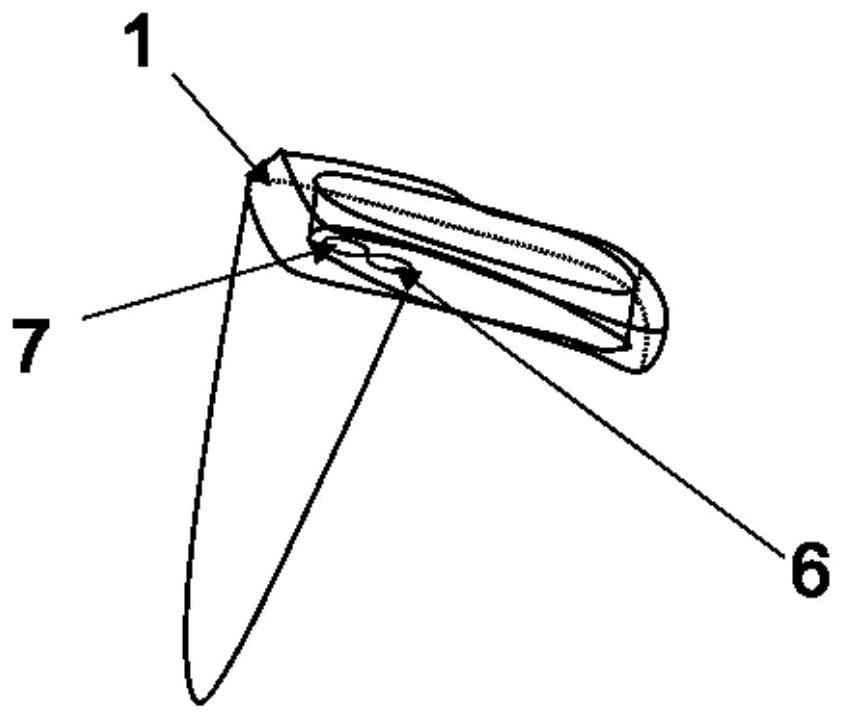

[0042] Such as figure 1 , as shown in 2 and 3, this embodiment provides a plug-type assembled multi-root dental implant structure based on SLM molding, including an integrated structure 1 of the mesial tooth root and the abutment, an integrated structure 2 of the distal tooth root and the abutment, and The crown 3 has three parts; the integrated structure of the distal root and the abutment 2 has a countersunk hole 5 and a first positioning pin hole 4 on the abutment, and the integrated structure of the mesial tooth root and the abutment 1 has a threaded hole 7 on the root And the second positioning pin hole 6 corresponding to the first positioning pin hole; the inverted taper screw 9 is screwed into the threaded hole 7 after passing through the countersunk hole 5, and the positioning is installed between the first positioning pin hole and the second positioning pin hole pin 8. another example Figure 5 , 6, a rectangular groove is set between the countersunk hole 5 and the ...

Embodiment 2

[0044] This embodiment provides the molding method of plug-type assembled multi-root dental implant structure in Embodiment 1. The method is based on SLM molding. The specific method includes the following steps:

[0045] 1. First, it is necessary to establish a personalized implant model according to the patient's teeth.

[0046] First, a CT scan of the patient's teeth is required. After the CT scan, the CT file is layered, and the tooth part and the soft tissue part are divided according to the gray value that cannot be tolerated. After processing the CT image, a model of the entire tooth can be obtained.

[0047] 2. After the tooth model is obtained, the tooth model needs to be divided into the same number of root and abutment integrated structures 1 or 2 and crown 3 according to the number of roots. The root of the integrated structure is used to implant the alveolar socket after the extraction of the affected tooth, which is responsible for fixing the entire tooth, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com