Brush-assisted ball screw force rheological polishing method

A ball screw and brush technology, used in grinding/polishing equipment, surface-polished machine tools, and parts of grinding machine tools, etc., can solve problems such as poor rigidity, high surface thread requirements, complex mechanism shapes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

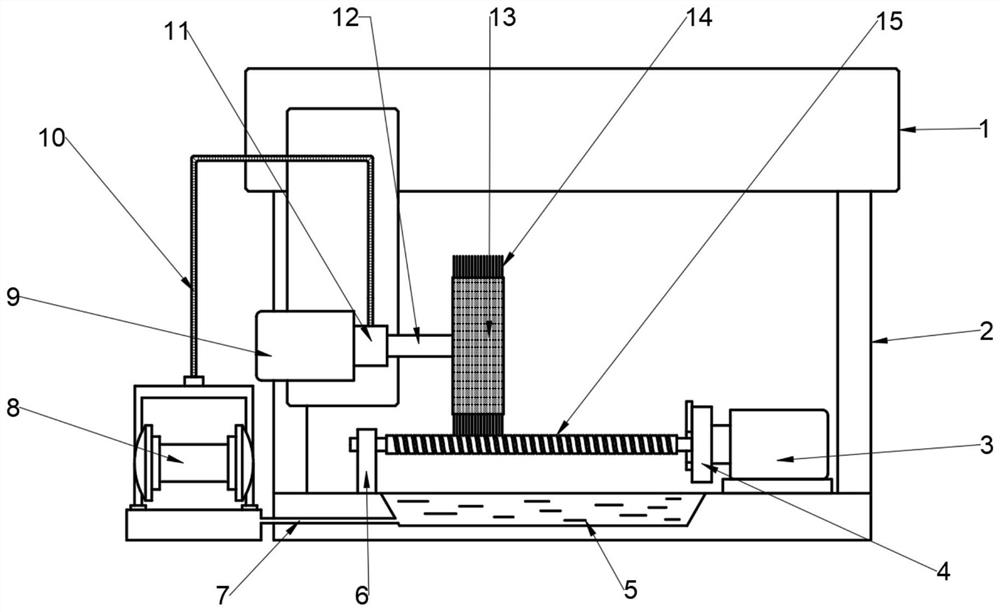

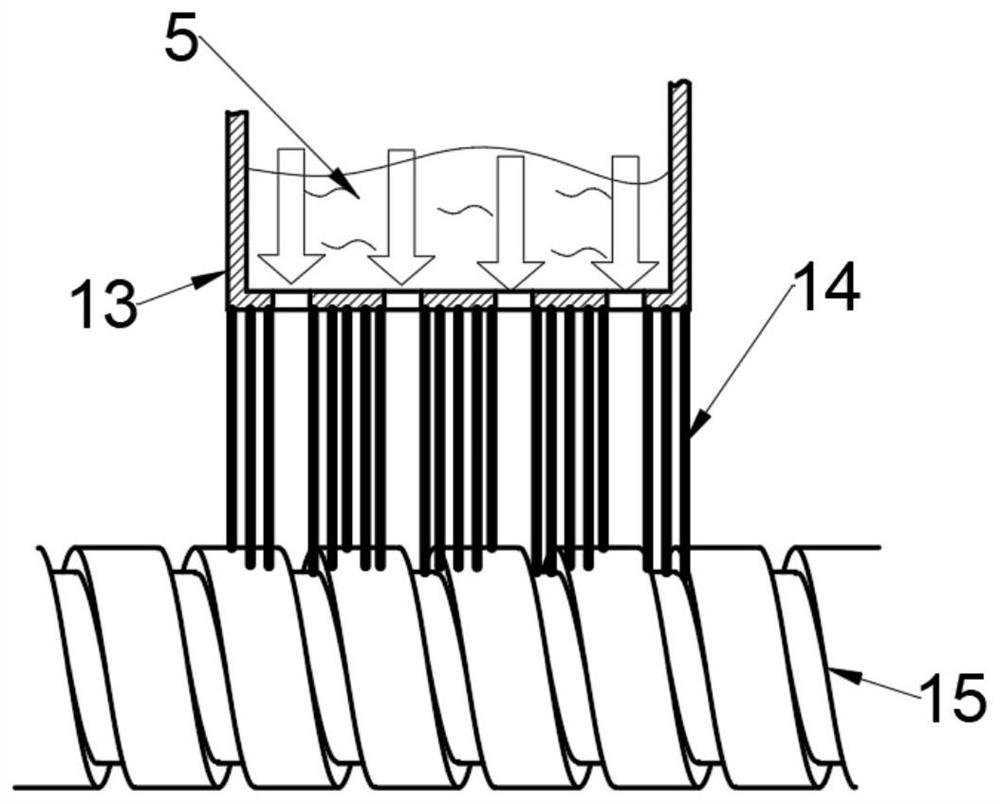

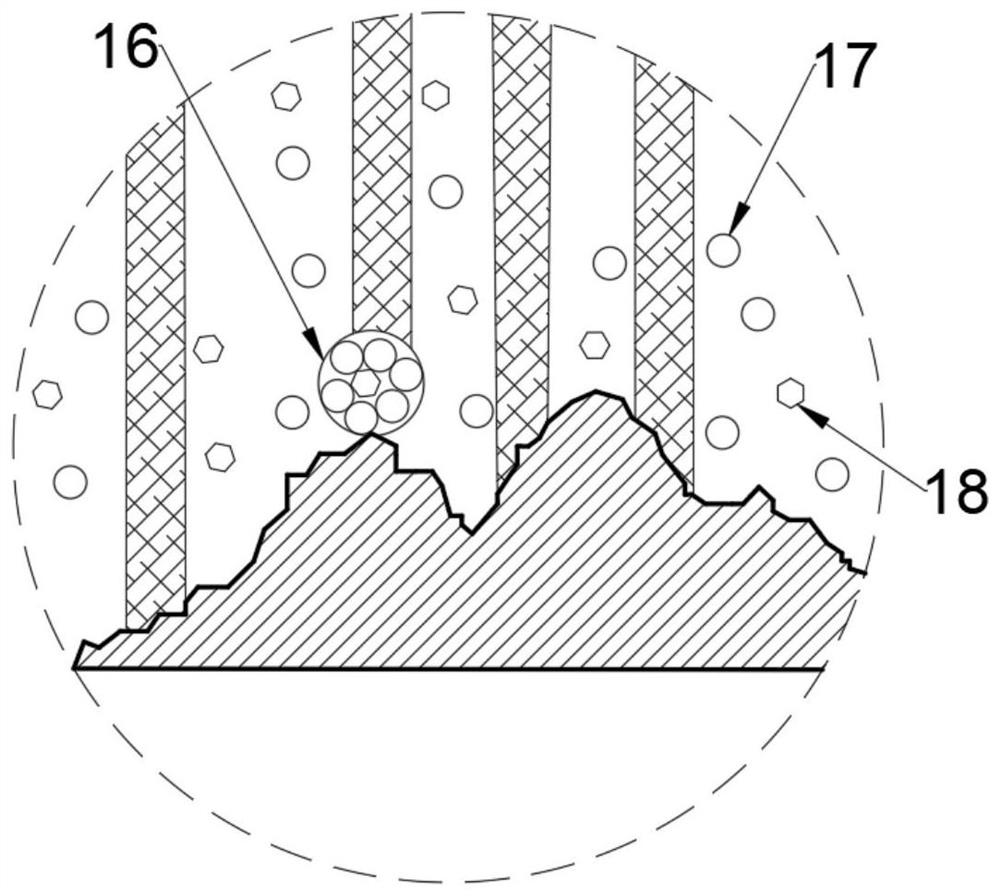

[0024] refer to Figure 1 ~ Figure 3 , a method of force-rheological polishing using a brush-assisted ball screw, said method comprising the following steps:

[0025] 1) Adding the mechano-rheological polishing fluid prepared by non-Newtonian fluid and abrasive grains in the polishing fluid tank;

[0026] 2) Clamp one end of the ball screw on the three-jaw chuck, and install the other end on the rotating bracket. Adjust the lifting system to make the brush on the polishing head contact the workpiece, turn on the diaphragm pump, and inject the polishing liquid into the hollow cavity of the polishing head through the flexible hose;

[0027] 3) During the processing, the polishing liquid is sprayed from the hollow cavity of the polishing head to the surface of the workpiece, and then the polishing liquid and the workpiece move relative to each other at a set speed, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com