Method for refining and purifying amorphous boron powder

A technology of amorphous boron powder and zirconia balls, applied in the direction of boron/boride, boron, etc., can solve the problems affecting the physical and chemical properties of boron powder, restrictions on the application of boron powder, low purity of boron powder, etc. Short, the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

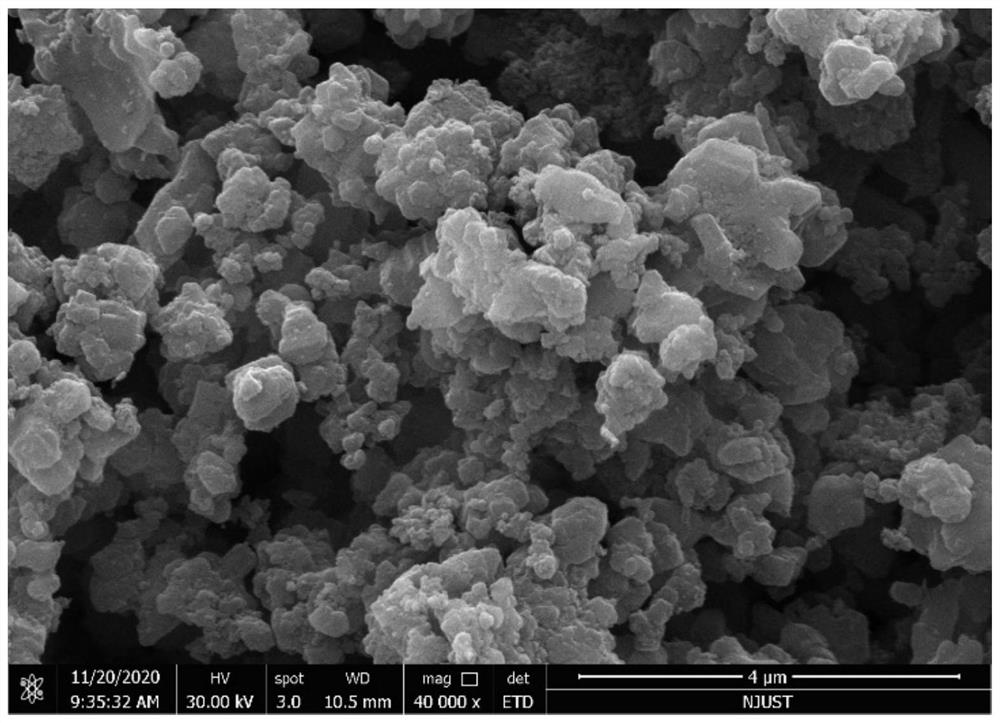

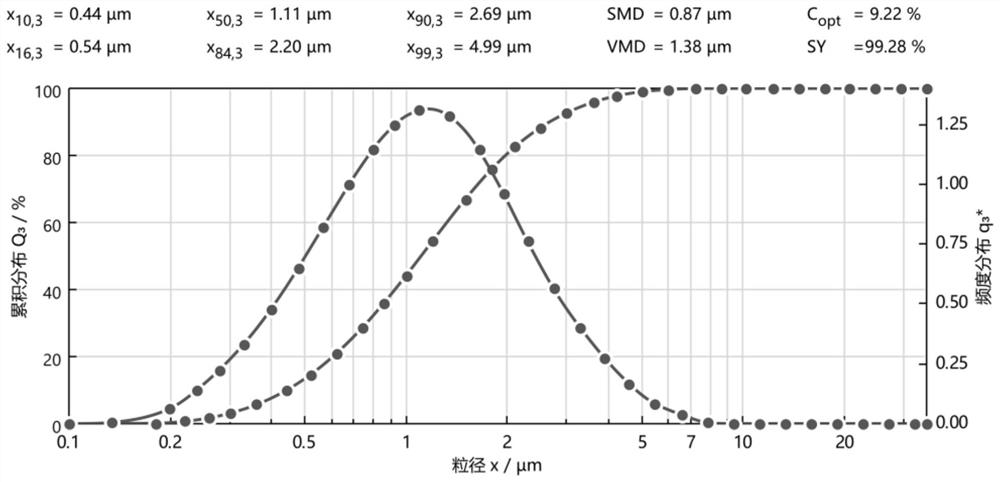

[0027] 1.0kg of commercially available amorphous boron powder, 0.5mol / L hydrochloric acid as the medium of acid ball milling, Φ3mm Al 2 o 3 As a grinding ball, the ball-to-material ratio is 6:1, the liquid-solid ratio is 2:1, and the rotation speed is 300rpm, and the acidic medium ball milling is carried out at 60°C for 4 hours; Wash with water for 20 minutes; after one wash, use 1.0mol / L sodium hydroxide as the medium of alkaline ball milling, Φ3mm Al 2 o 3 For grinding balls, the ball-to-material ratio is 6:1, the liquid-solid ratio is 2:1, and the rotation speed is 300rpm, and the alkaline medium ball milling is carried out at 80°C for 4 hours; 6 times of water washing for 20 minutes; after the second water washing, the filter cake of amorphous boron powder is vacuum-dried at 100° C. for 3 hours. The SEM photo of the amorphous boron powder after vacuum drying shows that its particle size is all below 2.0 μm ( figure 1 ), the particle size measured by laser particle size...

Embodiment 2

[0029] 1.0kg of commercially available amorphous boron powder, 1.0mol / L hydrochloric acid as the medium of acid ball milling, Φ3mm Al 2 o 3 As a grinding ball, the ball-to-material ratio is 6:1, the liquid-solid ratio is 2:1, and the rotation speed is 300rpm, and the acidic medium ball milling is carried out at 60°C for 6h; Wash with water for 20 minutes; after one wash, use 1.2mol / L sodium hydroxide as the medium of alkaline ball milling, Φ3mm Al 2 o 3 For grinding balls, the ratio of ball to material is 6:1, the ratio of liquid to solid is 2:1, and the rotation speed is 300rpm, and the alkaline medium ball milling is carried out at 80°C for 3 hours; after the alkaline medium ball milling, the amorphous boron powder is subjected to 60°C 6 times of water washing for 20 minutes; after the second water washing, the filter cake of amorphous boron powder is vacuum-dried at 100° C. for 3 hours. The boron content of the treated amorphous boron powder measured by the neutralizatio...

Embodiment 3

[0031] 1.0kg of commercially available amorphous boron powder, 1.0mol / L of hydrofluoric acid as the medium of acid ball milling, Φ3mm of Al 2 o 3As a grinding ball, the ball-to-material ratio is 6:1, the liquid-solid ratio is 3:1, and the rotation speed is 300rpm, and the acidic medium ball milling is carried out at 60°C for 8 hours; after the acidic medium ball milling, the amorphous boron powder is subjected to 2 Wash with water for 30 minutes; after one wash, use 1.0mol / L sodium hydroxide as the medium of alkaline ball milling, Φ3mm Al 2 o 3 For grinding balls, the ball-to-material ratio is 6:1, the liquid-solid ratio is 3:1, and the rotation speed is 300rpm, and the alkaline medium ball milling is carried out at 80°C for 4 hours; 6 times of water washing for 20 minutes; after the second water washing, the filter cake of amorphous boron powder is vacuum-dried at 100° C. for 3 hours. The boron content of the treated amorphous boron powder was measured by neutralization ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com