Preparation method of Co25Cr5W5Mo alloy spherical fine powder

A spherical, fine powder technology, applied in the field of powder alloys, can solve the problems of non-concentrated particle size distribution, coarse powder, etc., and achieve obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

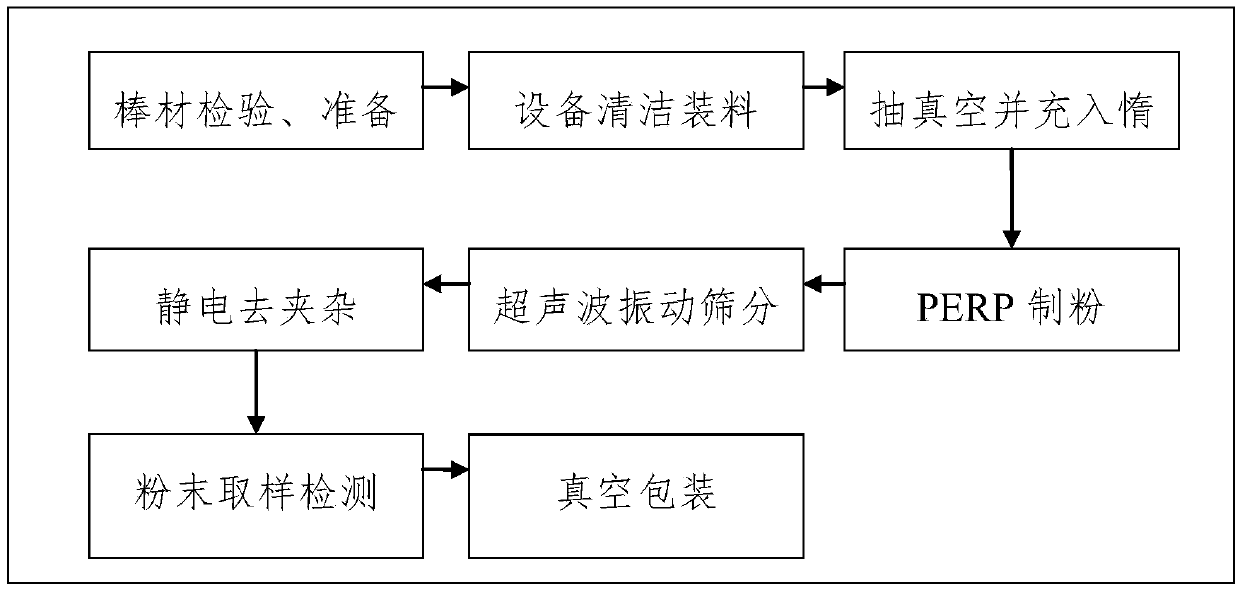

[0020] A kind of preparation method of Co25Cr5W5Mo alloy spherical fine powder of the present invention, as figure 1 As shown, the specific operation process includes the following steps:

[0021] Step 1, using the Co25Cr5W5Mo master alloy secondary smelting ingot-shaped blank obtained by secondary vacuum self-consumption smelting, the obtained master alloy secondary smelting ingot-shaped blank is machined by numerical control and lathe to obtain a powder that meets the requirements of plasma rotating electrode atomization. Required Co25Cr5W5Mo alloy rods;

[0022] The composition of the Co25Cr5W5Mo alloy rod obtained in step 1 is: Cr is 20.7-26.7%; W is 3.4-7.4%; Mo is 3.0-6.0%; Si is ≤ 1.5%, and the rest is Co; the specification of the Co25Cr5W5Mo alloy rod is : The diameter is 50mm-80mm, the length is 500mm-700mm, the surface roughness is 0.9μm-1.0μm, and the straightness is 0.010mm-0.020mm;

[0023] Step 2, put the Co25Cr5W5Mo alloy rod obtained in step 1 into the whole ...

Embodiment 1

[0041]Step 1, adopt the Co25Cr5W5Mo master alloy secondary smelting ingot-like billet obtained by secondary vacuum self-consumption smelting, and the obtained master alloy secondary smelting ingot-like billet is processed by numerical control and lathe to obtain a powder that meets the requirements of plasma rotating electrode atomization powder production. Co25Cr5W5Mo alloy bar, Co25Cr5W5Mo alloy bar composition includes Co as balance; Cr is 24.56%; W is 4.57%; Mo is 4.27%; Si is 0.48%; the specifications of Co25Cr5W5Mo alloy bar are: diameter 55mm, length is 700mm, the surface roughness is 0.946μm, and the straightness is 0.020mm;

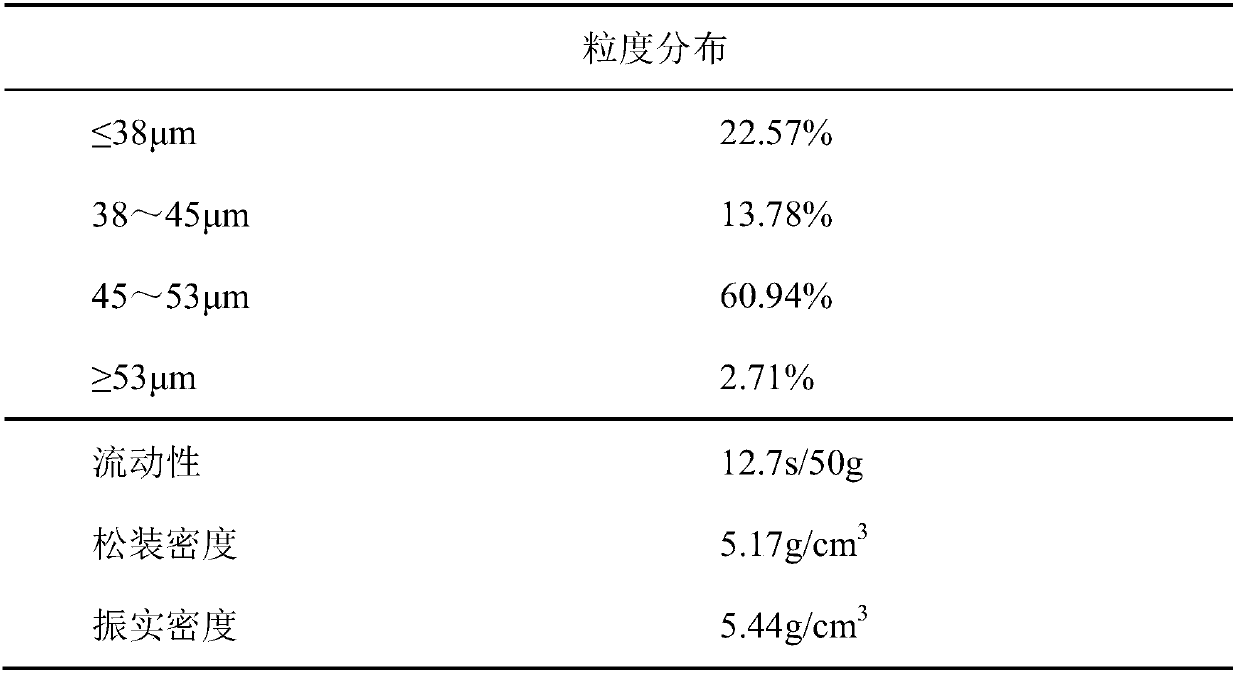

[0042] Step 2, place the Co25Cr5W5Mo alloy bar obtained in step 1 in the complete set of powder milling equipment for vacuum treatment, and fill with 35% argon and 65% helium mixed inert gas, the working pressure is 0.12MPa, and start the powder milling equipment. Atomization function, ignite the plasma generator at the same time, adjust the rota...

Embodiment 2

[0051] Step 1, adopt the Co25Cr5W5Mo master alloy secondary smelting ingot-like billet obtained by secondary vacuum self-consumption smelting, and the obtained master alloy secondary smelting ingot-like billet is processed by numerical control and lathe to obtain a powder that meets the requirements of plasma rotating electrode atomization powder production. The Co25Cr5W5Mo alloy bar, the composition of the Co25Cr5W5Mo alloy bar includes Cr 24.50%; W 4.60%; Mo 4.32%; Si 0.49%; is 500mm, the surface roughness is 0.98μm, and the straightness is 0.010mm;

[0052] In step 2, the Co25Cr5W5Mo alloy bar obtained in step 1 is placed in a complete set of powder milling equipment for vacuum treatment, and filled with 35% argon and 65% helium mixed inert gas, the working pressure is 0.15MPa, and the powder milling equipment is started. Atomization function, ignite the plasma generator at the same time, adjust the rotation speed of the Co25Cr5W5Mo alloy bar to 30000r / min, use the plasma g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com