Solid waste-based thermally-induced coagulation 3D printing material and 3D printing forming method thereof

A 3D printing and thermogenic technology, applied in the direction of additive processing, etc., can solve the problems of difficulty in practical application, long setting time, limited materials, etc., and achieve the effects of controllable setting time, expanded application range and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

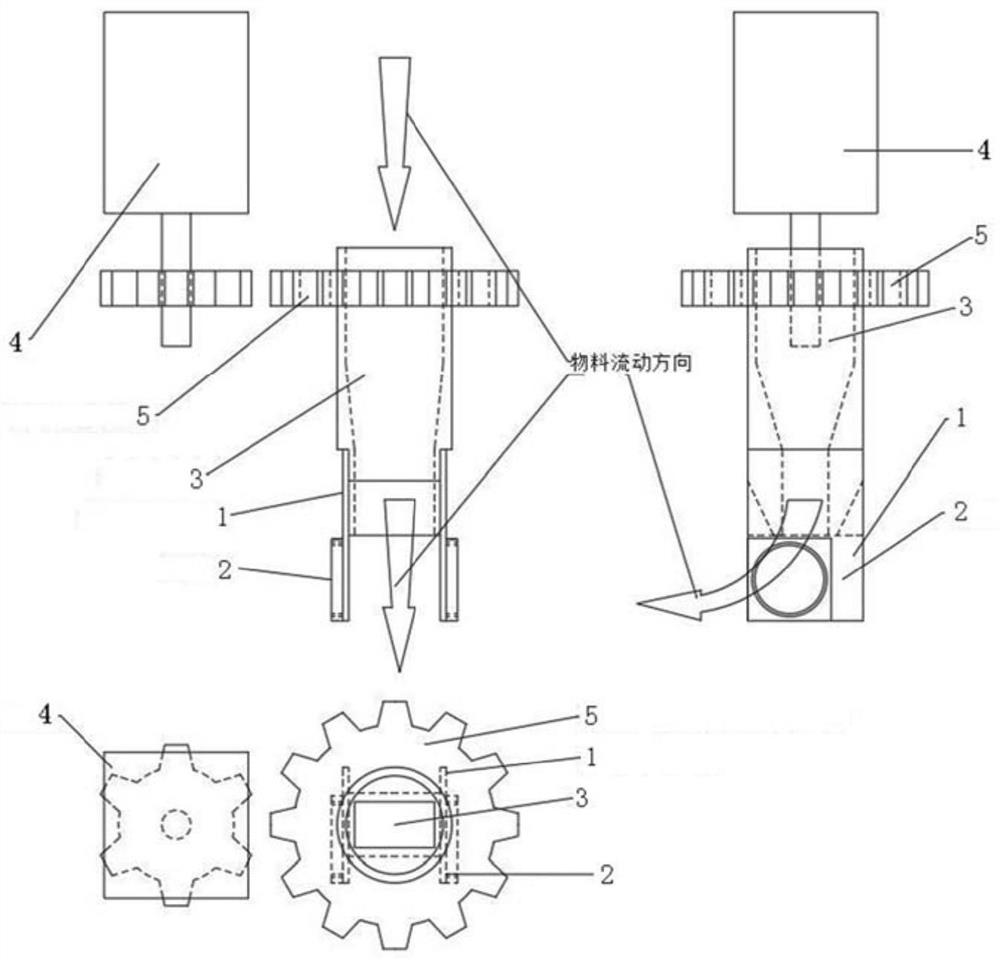

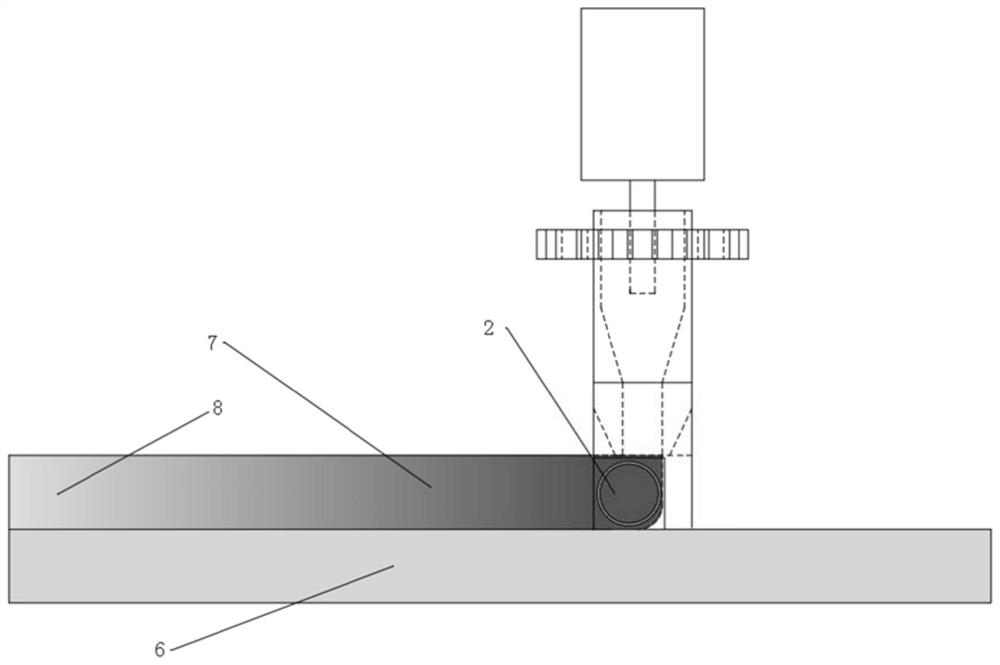

Image

Examples

Embodiment 1

[0030] A solid waste-based heat-induced coagulation-accelerated 3D printing material, the preparation method of which is as follows:

[0031] 1) Prepare material A: mix 600g steel slag, 40g emulsified paraffin, and 45g potassium thiosulfate to obtain material A;

[0032] 2) Prepare material B: mix 500g of water, 20g of polycarboxylate superplasticizer, and 30g of attapulgite to obtain material B;

[0033] 3) Preparation of solid waste-based cementitious material: Add 200g of cement clinker, 100g of silica fume, 400g of slag and 200g of phosphogypsum into the mixer, and stir evenly to obtain solid waste-based cementitious material;

[0034] 4) Add material A prepared in step 1) and material B prepared in step 2) sequentially to the solid waste-based cementitious material obtained in step 3), stir until it is uniform slurry, add 750g of quartz sand fine aggregate and continue stirring, stirring After uniformity, the solid waste-based thermally induced coagulation 3D printing ma...

Embodiment 2

[0037] Using a method similar to Example 1 to prepare solid waste-based thermocoagulant 3D printing materials and print concrete products, the difference between this example and Example 1 is that the rheology modifiers used are 20g starch ether and 10g cellulose ether mixture.

Embodiment 3

[0039] The method similar to Example 1 was used to prepare solid waste-based thermally induced coagulation-accelerated 3D printing materials and print concrete products. The difference between this example and Example 1 is that the phase change material used is 40 g of sodium acetate trihydrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com