High-elasticity, repairable, super-durable and harmlessly treatable ionic conductor membrane and preparation method thereof

A technology of harmless treatment and ionic conductors, applied in the field of stretchable ionic conductors, can solve the problems that ionic conductors have not been prepared, and achieve stable and reliable electrical properties, excellent elasticity and fatigue resistance, and good durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

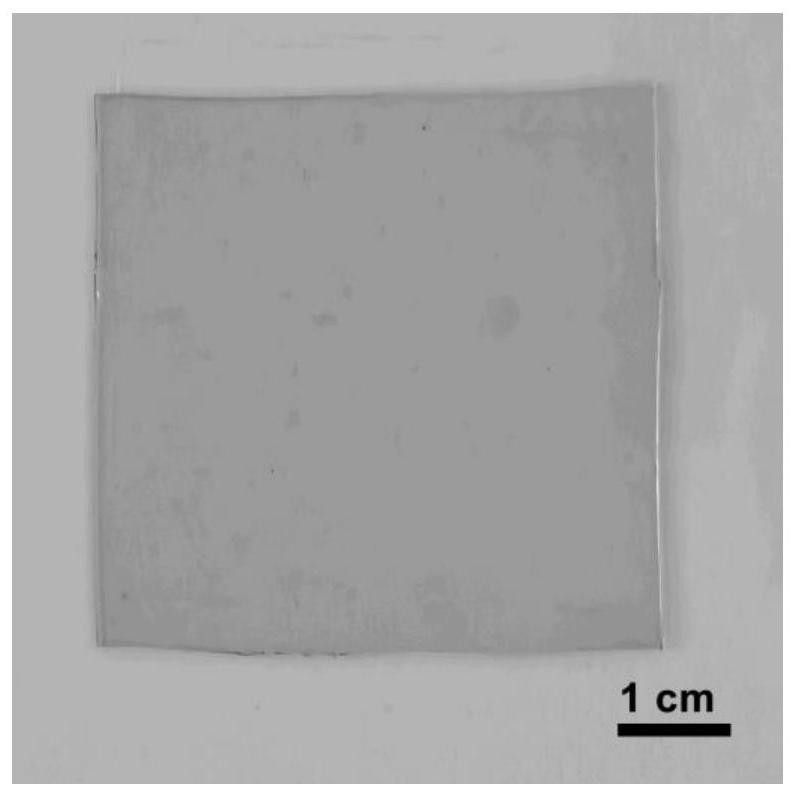

Image

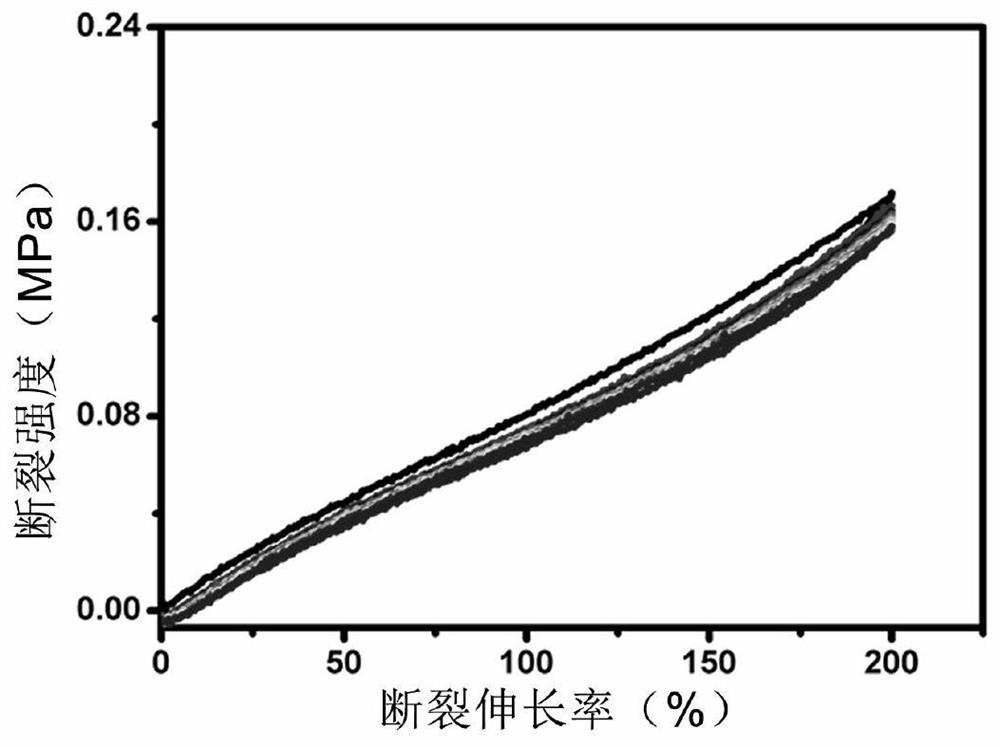

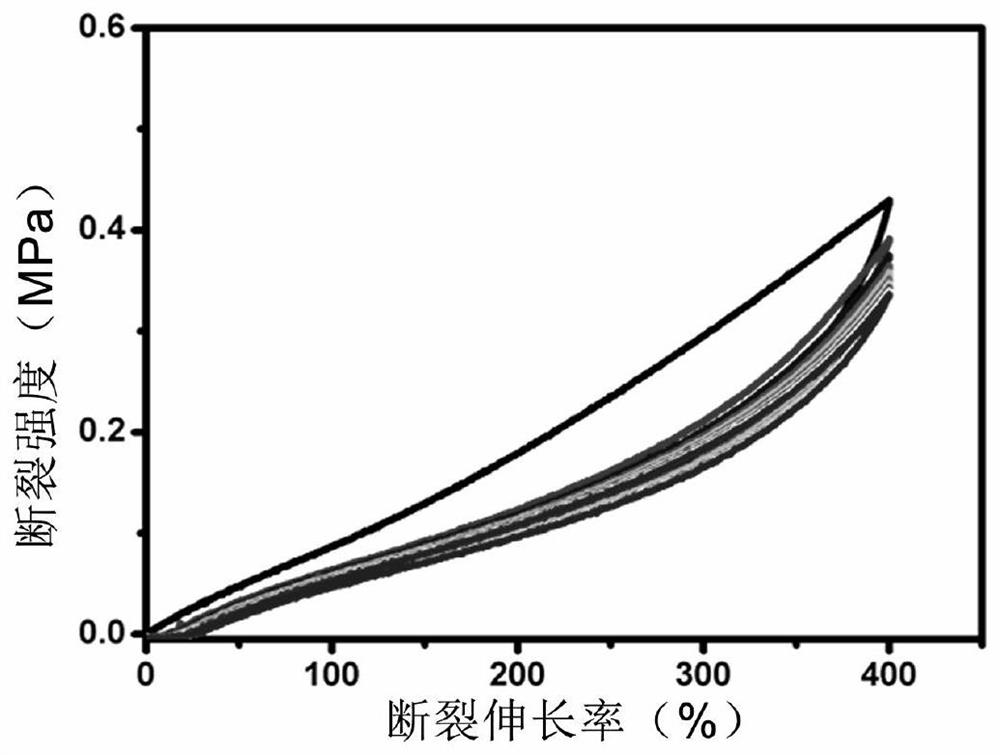

Examples

Embodiment 1

[0026] Example 1: A method for preparing an ion conductor with high elasticity, repairability, ultra-durability and harmless treatment

[0027] Dissolve 5g of PVA (hydrolysis degree above 99%, molecular weight 146k ~ 186k) in 70ml DMSO at 90°C, then add 1M hydrochloric acid (3.3mL, hydrochloric acid 0.12g), and then add 3.45g of B-vanilla to the solution Aldehyde modifier (the molar percentage of grafting is 40%, and the modifier accounts for the repeating structural unit of PVA (ie-C2 h 4 The molar percentage of O-) is 20%); Wherein, the massfraction of PVA is 5.6%, the massfraction of vanillin (modifier) is 3.9%, the massfraction of hydrochloric acid (catalyst) is 0.14%; And at 80 ℃ Stirring and reacting for 8h under the conditions, so that the modifier is covalently grafted onto the polymer to obtain a polymer matrix solution (obtaining 88.87g of a polymer matrix solution, wherein the mass of the polymer matrix is 8.04g, and the mass fraction is 9.0%, Because 1 mole of...

Embodiment 2

[0029] Example 2: A method for preparing an ion conductor with high elasticity, repairability, ultra-durability and harmless treatment

[0030] Dissolve 5g of PVA (hydrolysis degree above 99%, molecular weight 146k~186k) into 70ml of organic solvent DMSO at 90°C, then add 1M hydrochloric acid (3.3mL, 0.12g of hydrochloric acid), and then add modifier to the solution 3.88g B-vanillin (grafting molar percentage is 45%, modifier accounts for the repeating structural unit of PVA (being-C 2 h 4 The molar percentage of O-) is 22.5%), wherein, the massfraction of PVA is 5.6%, the massfraction of vanillin (modifier) is 4.3%, the massfraction of hydrochloric acid (catalyst) is 0.13%; And at 80 ℃ Stirring and reacting for 8h under the condition, thereby the modifying agent is covalently grafted onto the polymer to obtain a polymer matrix solution (obtaining 89.3g of a polymer matrix solution, wherein the mass of the polymer matrix is 8.42g, and the mass fraction is 9.4%, Because 1...

Embodiment 3

[0032] Example 3: A method for preparing an ion conductor with high elasticity, repairability, ultra-durability and harmless treatment

[0033] Dissolve 5g of PVA (hydrolysis degree above 99%, molecular weight 146k~186k) into 70ml of organic solvent DMSO at 90°C, then add 1M hydrochloric acid (3.3mL, 0.12g of hydrochloric acid), and then add modifier to the solution 3.02g B-vanillin (grafting molar percentage is 35%, modifier accounts for the repeating structural unit of PVA (being-C 2 h 4 The molar percentage of O-) is 16.5%), wherein, the massfraction of PVA is 5.7%, the massfraction of vanillin (modifier) is 3.4%, the massfraction of hydrochloric acid (catalyst) is 0.14%; And at 80 ℃ Stirring and reacting for 8h under the condition, thereby modifier covalently grafted on the polymer, obtain polymer matrix solution (obtain polymer matrix solution 88.44g, wherein the quality of polymer matrix is 7.66g, mass fraction is 8.7%, Because 1 mole of vanillin and 1 mole of wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com