A steel cofferdam caulking treatment method in the construction process of a sea-crossing bridge

A treatment method and a technology of the construction process, which are applied in the fields of construction, infrastructure engineering, climate change adaptation, etc., can solve problems such as difficulty in waterproofing and sealing foundation pit protection structures, unsatisfactory practicability, and rubber strips being washed away, etc., so as to avoid disadvantages Influence, reduce drilling resistance, ensure the effect of water blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

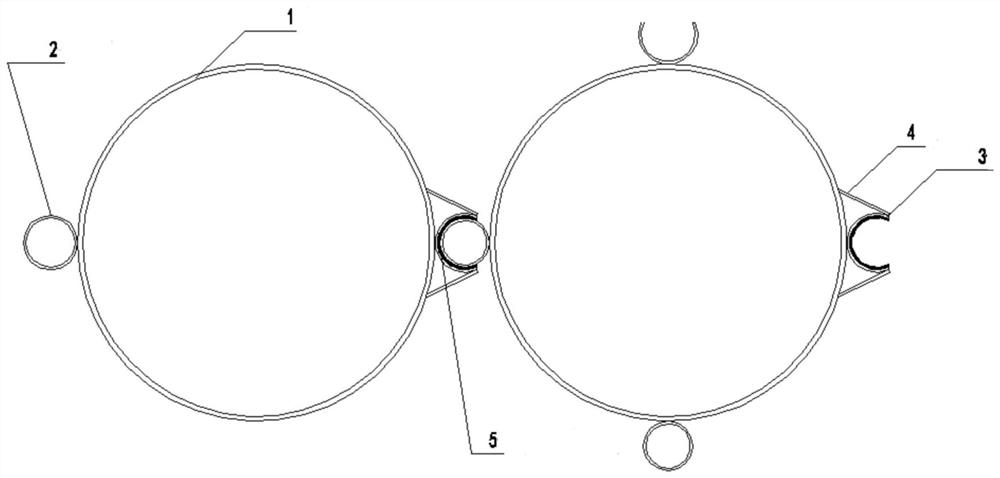

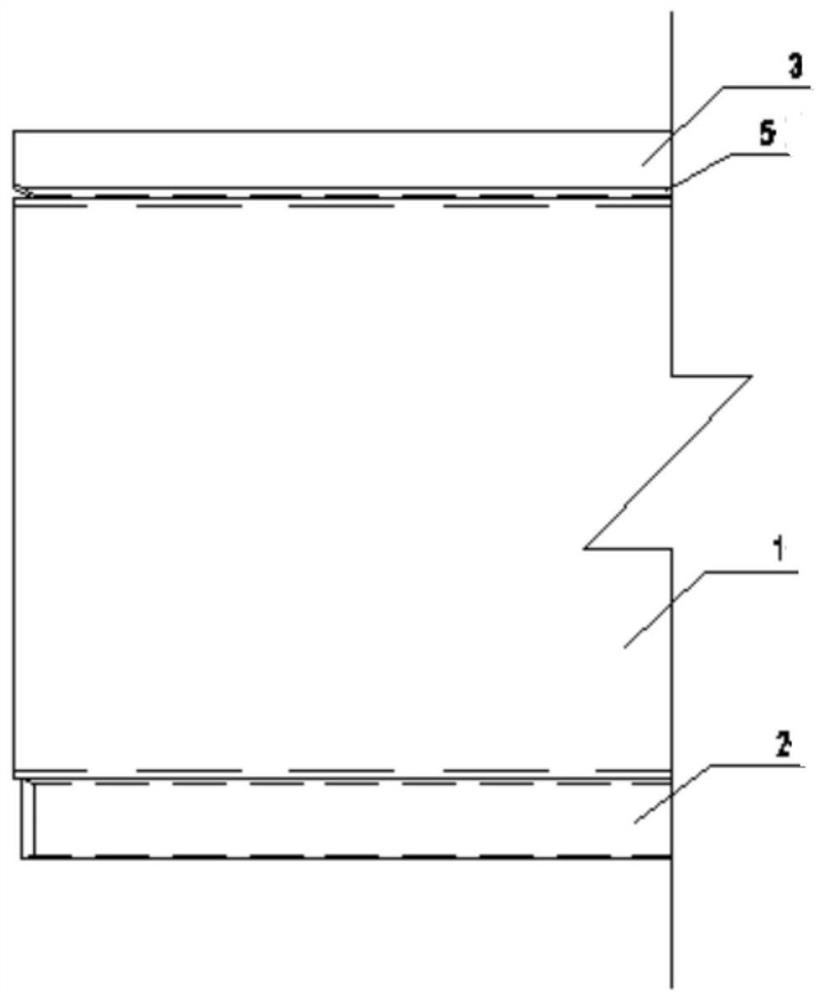

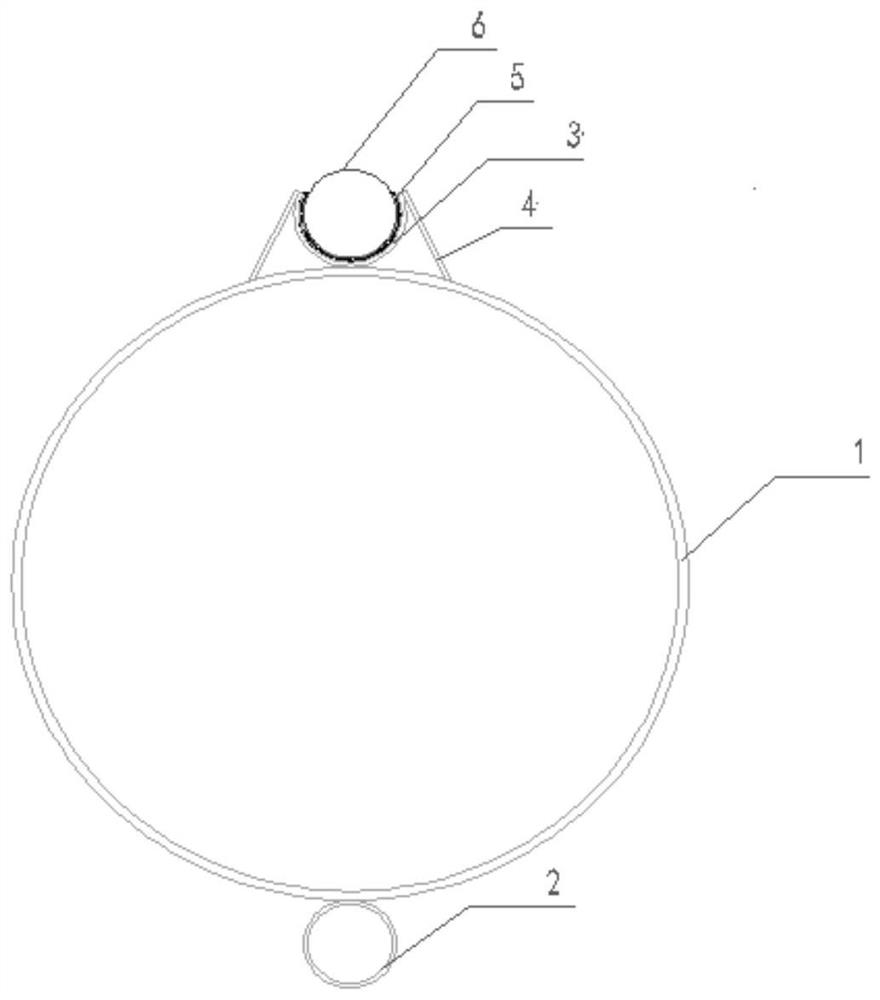

[0031] figure 1 It is a schematic diagram for demonstrating the connection when the locking steel pipe pile is water-proof and plugged, figure 2 It is a schematic diagram showing the positional relationship between the yin and yang locks of the lock steel pipe pile and the elastomer water barrier. The following will combine figure 1 and figure 2 , to specifically explain the entire processing process according to the present invention.

[0032] First, on the opposite side of the outer wall of the steel pipe pile body, such as a threaded welded pipe, an open-type steel pipe as the fem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com