Chip resistor fine etching machine

A chip resistor and precision engraving technology, which is applied in the direction of resistors, resistor manufacturing, and resistor manufacturing through photolithography, etc., can solve the problem of large impact on the resistance adjustment accuracy and resistance adjustment pass rate of chip resistors, low efficiency, and grinding Uneven etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

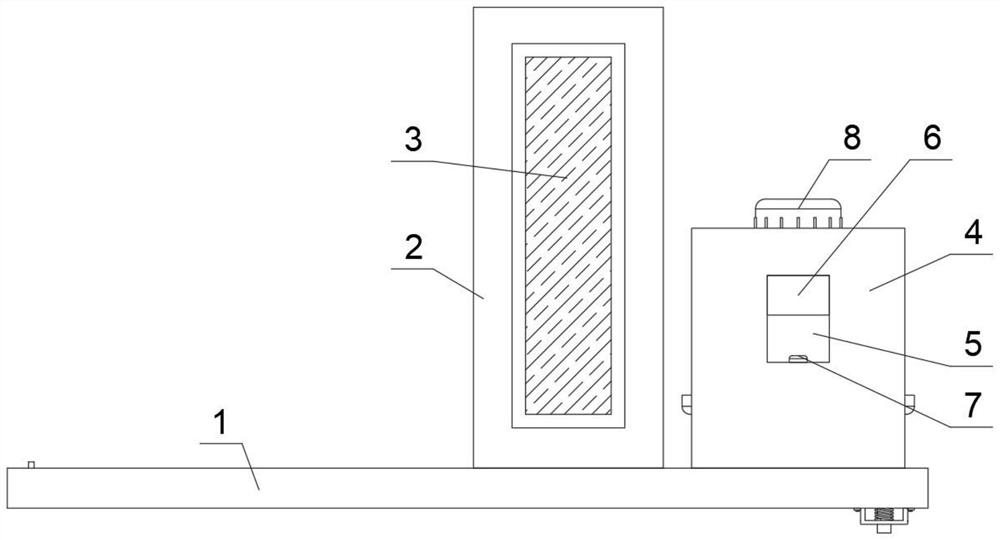

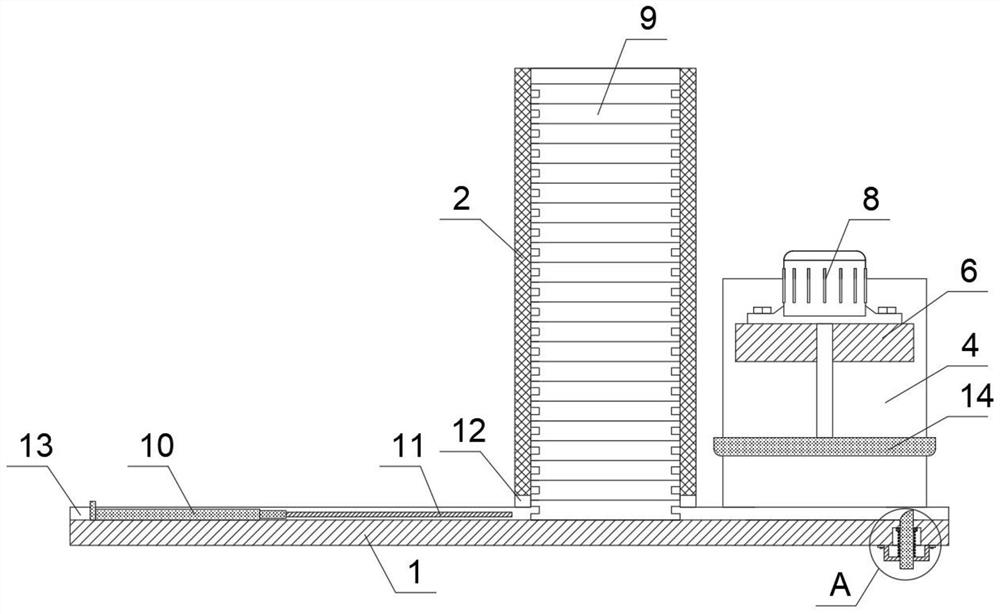

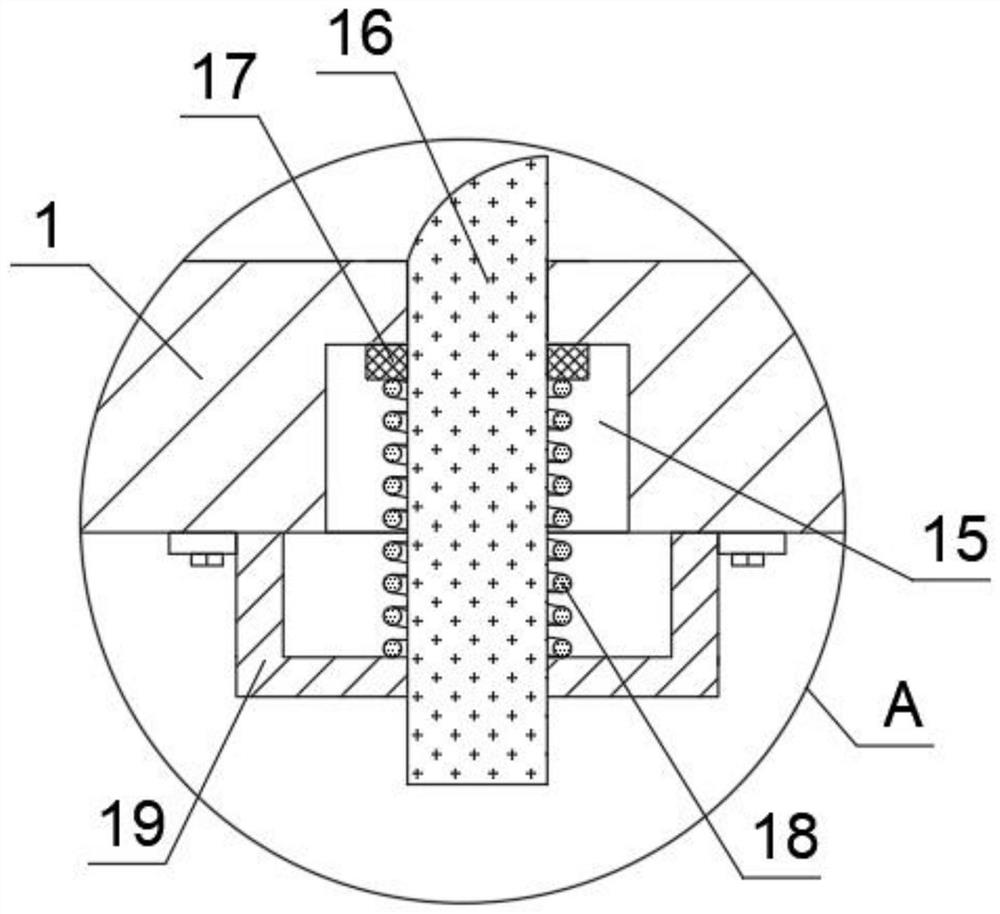

[0036] Examples, see Figure 1-5, the present invention provides a technical solution: a chip resistor precision engraving machine, including a track base plate 1, the inside of the track base plate 1 has a track chute 13, and the top of the track base plate 1 is fixedly connected with two track support plates distributed in parallel 4. A gravity skateboard 6 is slidably connected between the two track support plates 4. The inside of the track support plate 4 has a slide plate groove 5 for the gravity slide plate 6 to slide. The inner bottom of the slide plate groove 5 is equipped with a trigger switch 7. The gravity slide plate 6 A driving motor 8 is installed on the top, and the bottom of the output shaft of the driving motor 8 is fixedly connected with a chip resistor grinding disc 14, and the bottom of the outer end surface of the chip resistor grinding disc 14 is provided with rounded corners, and the top of the track base plate 1 is fixedly connected with a top and a The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com