Iron-silicon composite magnetic powder core with surface coating structure and preparation method of iron-silicon composite magnetic powder core

A surface coating and magnetic powder core technology, which is applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve problems such as unfavorable green development, large air pollution, and cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

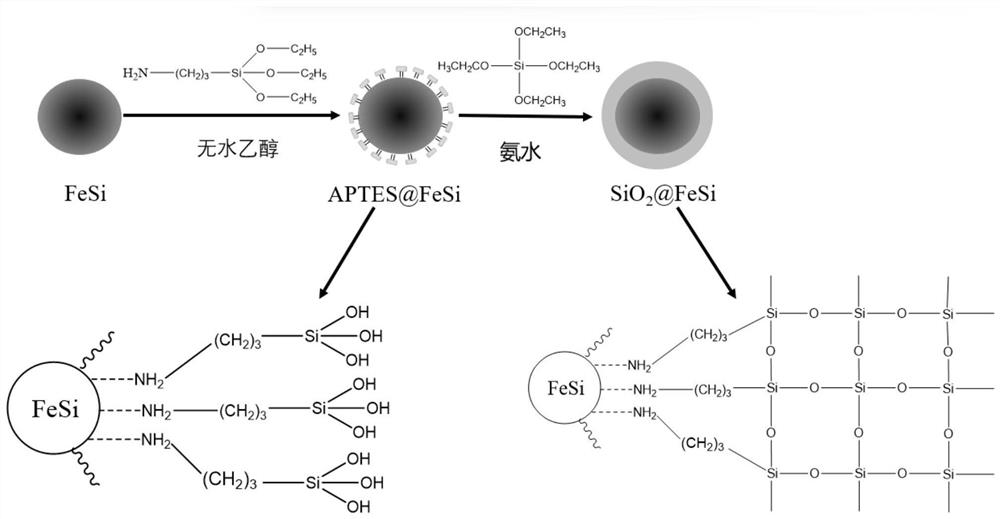

[0038] use as figure 1 The synthetic route shown for the preparation of SiO 2 The Fe-6.5wt% Si magnetic powder core of coating, concrete steps are as follows:

[0039] Add 5gFe-6.5wt%Si magnetic powder into 167mL of absolute ethanol, stir mechanically for 10 minutes at a stirring speed of 200rpm to disperse the magnetic powder evenly, then slowly raise the temperature to 50°C, slowly add 0.6g γ-aminopropyltriethyl Oxysilane (APTES), then mechanically stirred at 50°C for 2h; then slowly warmed up to 60°C, first slowly added 2mL of ammonia water dropwise, and then slowly added 4mL of tetraethoxysilane (orthosilicate) for 2h After the dropwise addition, continue the mechanical stirring reaction for 6h, filter after the reaction, wash with absolute ethanol, and vacuum dry at 50°C for 24h to obtain SiO 2 Coated Fe-6.5wt% Si magnetic powder core. During the experiment, the slow temperature rise rate was 2.5°C / min; the slow drop rate of γ-aminopropyltriethoxysilane (APTES) was 0.2...

Embodiment 2

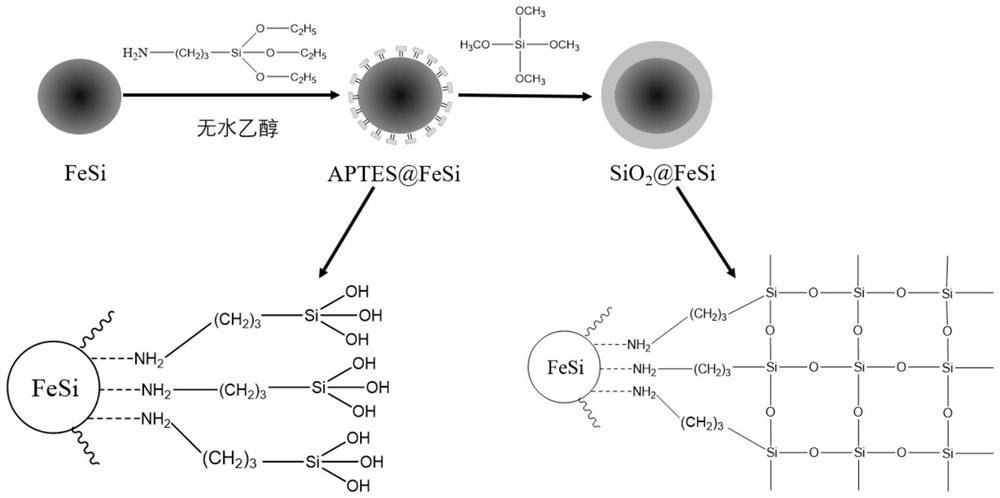

[0046] use as figure 1 The synthetic route shown for the preparation of SiO 2 The Fe-6.5wt% Si magnetic powder core of coating, concrete steps are as follows:

[0047] Add 5gFe-6.5wt%Si magnetic powder into 200mL of absolute ethanol, stir mechanically for 10 minutes at a stirring speed of 200rpm to disperse the magnetic powder evenly, then slowly raise the temperature to 50°C, slowly add 0.6g γ-aminopropyl triethyl Oxysilane (APTES), then mechanically stirred at 50°C for 2h, then slowly warmed up to 60°C, first slowly added 2mL of ammonia water dropwise, and then slowly added dropwise with 4mL tetraethoxysilane (ethyl orthosilicate) for 2h After the dropwise addition, continue the mechanical stirring reaction for 6h, filter after the reaction, wash with absolute ethanol, and vacuum dry at 50°C for 24h to obtain SiO 2 Coated Fe-6.5wt% Si magnetic powder core. During the experiment, the slow temperature rise rate was 2.5°C / min; the slow drop rate of γ-aminopropyltriethoxysila...

Embodiment 3

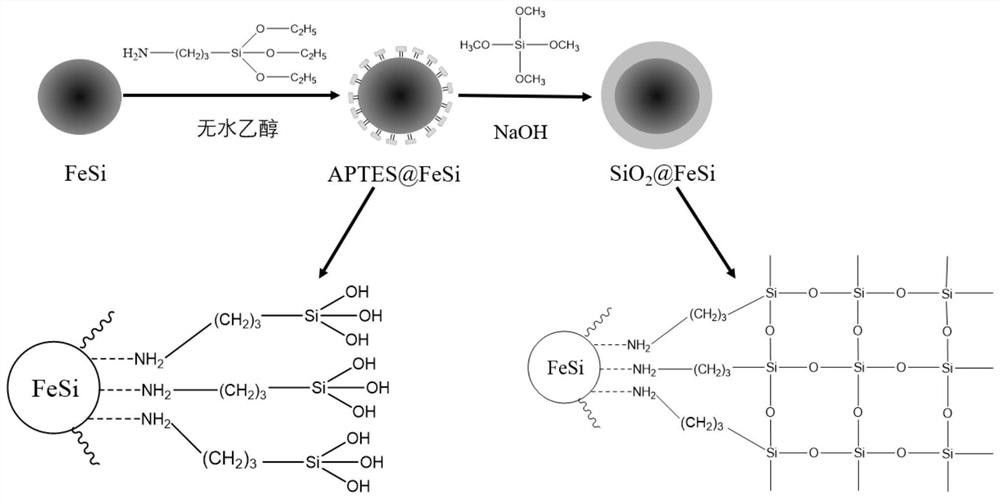

[0054] use as figure 1 The synthetic route shown for the preparation of SiO 2 The Fe-6.5wt% Si magnetic powder core of coating, concrete steps are as follows:

[0055] Add 5gFe-6.5wt%Si magnetic powder into 250mL of absolute ethanol, stir mechanically for 10 minutes at a stirring speed of 200rpm to disperse the magnetic powder evenly, then slowly raise the temperature to 50°C, slowly add 0.6g γ-aminopropyl triethyl Oxysilane (APTES), then mechanically stirred at 50°C for 2h, then slowly warmed up to 60°C, first slowly added 2mL of ammonia water dropwise, and then slowly added dropwise with 4mL tetraethoxysilane (ethyl orthosilicate) for 2h After the dropwise addition, continue the mechanical stirring reaction for 6h, filter after the reaction, wash with absolute ethanol, and vacuum dry at 50°C for 24h to obtain SiO 2 Coated Fe-6.5wt% Si magnetic powder core. During the experiment, the slow temperature rise rate was 2.5°C / min; the slow drop rate of γ-aminopropyltriethoxysila...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com